Question: Consider a hardware supply warehouse that is contractually obligated to deliver 2,000 units of a specialized fastener to a local manufacturing company each week. Each

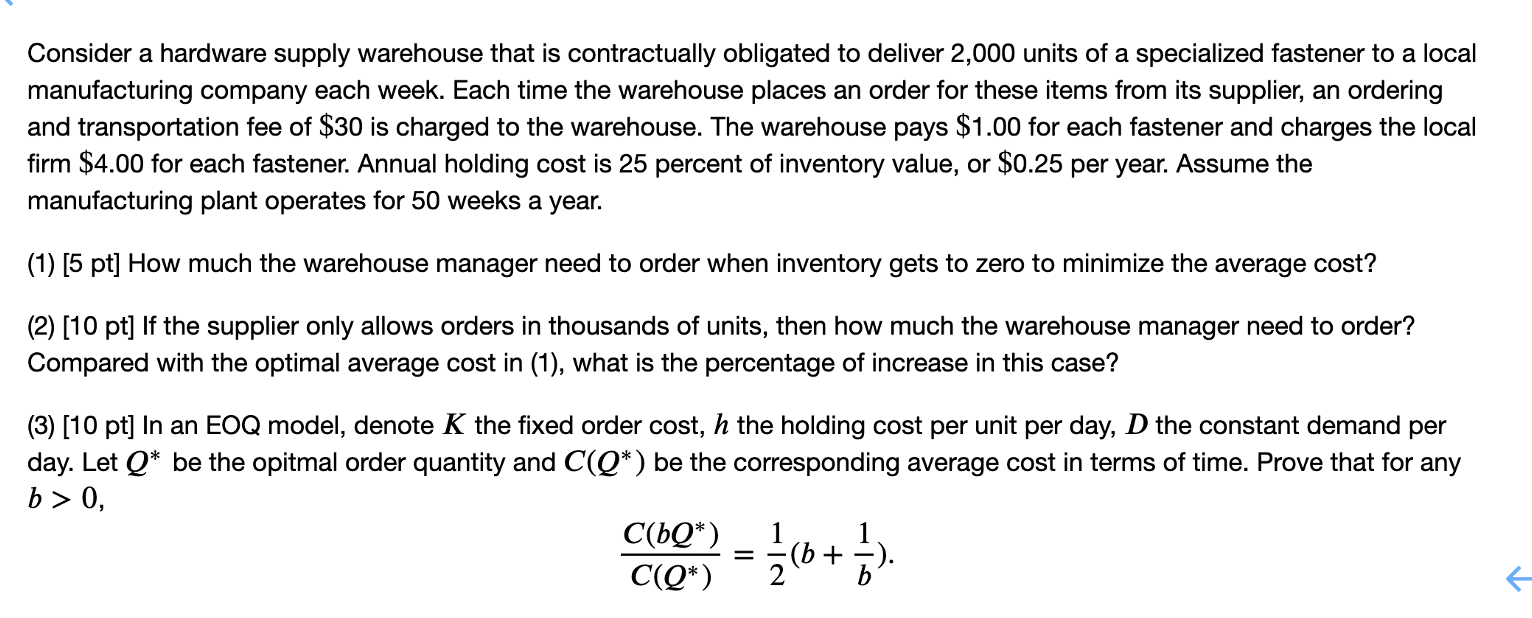

Consider a hardware supply warehouse that is contractually obligated to deliver 2,000 units of a specialized fastener to a local manufacturing company each week. Each time the warehouse places an order for these items from its supplier, an ordering and transportation fee of $30 is charged to the warehouse. The warehouse pays $1.00 for each fastener and charges the local firm $4.00 for each fastener. Annual holding cost is 25 percent of inventory value, or $0.25 per year. Assume the manufacturing plant operates for 50 weeks a year. (1) [5 pt] How much the warehouse manager need to order when inventory gets to zero to minimize the average cost? (2) [10 pt] If the supplier only allows orders in thousands of units, then how much the warehouse manager need to order? Compared with the optimal average cost in (1), what is the percentage of increase in this case? (3) [10 pt] In an EOQ model, denote K the fixed order cost, h the holding cost per unit per day, D the constant demand per day. Let Q be the opitmal order quantity and C(Q) be the corresponding average cost in terms of time. Prove that for any b>0 C(Q)C(bQ)=21(b+b1)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts