Question: EXAMPLE 2 - 4 Recall the hardware supply warehouse from the previous example. Now, rather than delivering 1 , 0 0 0 units of a

EXAMPLE

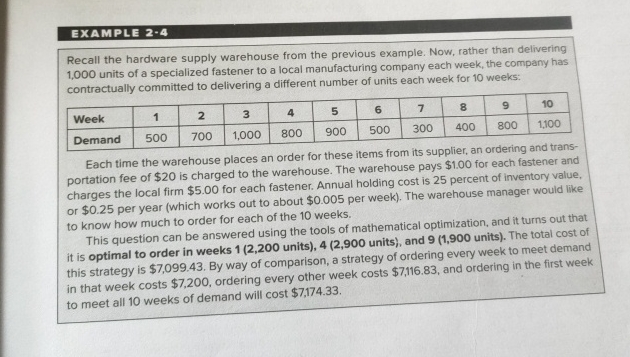

Recall the hardware supply warehouse from the previous example. Now, rather than delivering units of a specialized fastener to a local manufacturing company each week, the company has contractually committed to delivering a different number of units each week for weeks:

tableWeekDemand

Each time the warehouse places an order for these items from its supplier, an ordering and transportation fee of $ is charged to the warehouse. The warehouse pays $ for each fastener and charges the local firm $ for each fastener. Annual holding cost is percent of inventory value. or $ per year which works out to about $ per week The warehouse manager would like to know how much to order for each of the weeks.

This question can be answered using the tools of mathematical optimization, and it turns out that it is optimal to order in weeks units units and units The total cost of this strategy is $ By way of comparison, a strategy of ordering every week to meet demand in that week costs $ ordering every other week costs $ and ordering in the first week to meet all weeks of demand will cost $

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock