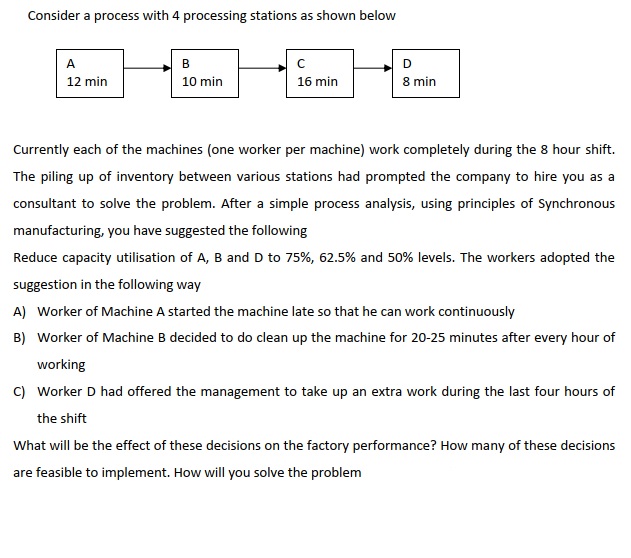

Question: Consider a process with 4 processing stations as shown below 12 min 10 min 16 min 3min Currently each of the machines [one worker per

Consider a process with 4 processing stations as shown below 12 min 10 min 16 min 3min Currently each of the machines [one worker per machine] work completely during the 8 hour shift. The piiing up of inventory between various stations had prompted the company to hire you as a consultant to solve the problem. After a simple process analysis, using principles of Synchronous ma nufacturing, you have suggested the following Reduce capacity utilisation of A, B and D to 75%, 52.5% and 50% ievels. The workers adopted the suggestion in the following way A} Worker of Machine A started the machine late so that he can work continuously B] Worker of Machine B decided to do clean up the machine for 2025 minutes after every hour of working [2} Worker D had offered the management to take up an extra work during the last four hours of the shift What will be the effect of these decisions on the factory performance? How many of these decisions are feasibie to implement. How will you solve the

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts