Question: Consider a single-pump circuit that transports a process fluid containing some solids from a storage tank to a pressurized tank. A heat exchanger heats the

Consider a single-pump circuit that transports a process fluid containing some solids from a storage tank to a pressurized tank. A heat exchanger heats the fluid, and a control valve regulates the rate of flow into the pressurized tank to 80 cubic meters per hour or 350 gallons per minute (gpm). The process is depicted in Figure 6.8. The plant engineer is experiencing problems with a fluid control valve (FCV) that fails due to erosion caused by cavitations. The valve fails every 10 to 12 months at a cost of $4,000 per repair. A change in the control valve is being considered: Replace the existing valve with one that can resist cavitations. Before the control valve is repaired again, the project engineer wants to look at other options and perform an LCCA on alternative solutions.

Engineering Solution Alternatives The first step is to determine how the system is currently operating and why the control valve fails. Then the engineer can see what can be done to correct the problem. The control valve currently operates between 15 and 20% open and with considerable cavitation noise from the valve. It appears that the valve was not sized properly for the application. After reviewing the original design calculations, it was discovered that the pump was oversized: (485 gpm) instead of (350 gpm). This resulted in a larger pressure drop across the control valve than was originally intended. As a result of the large differential pressure at the operating rate of flow, and because the valve is showing cavitation damage at regular intervals, the engineer determines that the control valve is not suitable for this process. The following four options are suggested:

• Option A. A new control valve can be installed to accommodate the high pressure differential.

• Option B. The pump impeller can be trimmed so that the pump does not develop as much head, resulting in a lower pressure drop across the current valve.

• Option C. A variable-frequency drive (VFD) can be installed and the flow control valve removed. The VFD can vary the pump speed and thus achieve the desired process flow.

• Option D. The system can be left as it is, with a yearly repair of the flow control valve to be expected.

For each option, the major cost elements identified are as follows:

• Option A. The cost of a new control valve that is properly sized is $5,000. The cost of modifying the pump’s performance by reducing the diameter of the impeller is $2,250. The process operates at for 6,000 h/year. The energy cost is $0.08 per kWh and the motor efficiency is 90%.

• Option B. By trimming the impeller to 375 mm, the pump’s total head is reduced to 42.0 m (138 ft) at This drop in pressure reduces the differential pressure across the control valve to less than 10 m (33 ft), which better matches the valve’s original design intent. The resulting annual energy cost with the smaller impeller is $6,720 per year. It costs $2,250 to trim the impeller. This cost includes the machining cost as well as the cost to disassemble and reassemble the pump.

• Option C. A 30-kW VFD costs $20,000 and an additional $1,500 to install. The VFD will cost $500 to maintain each year. It is assumed that it will not need any repairs over the project’s eight-year life.

• Option D. The option to leave the system unchanged will result in a yearly cost of $4,000 for repairs to the cavitating flow control value.

Given: Financial data as summarized in Table 6.1. Find: Which design option to choose. Assumptions:

• The current energy price is $0.08/kWh.

• The process is operated for 6,000 hours/year.

• The company has a cost of $500 per year for routine maintenance of pumps of this size, with a repair cost of $2,500 every second year.

• There is no decommissioning cost or environmental disposal cost associated with this project.

• The project has an eight-year life.

• The interest rate for new capital projects is 8%, and an inflation rate of 4% is expected

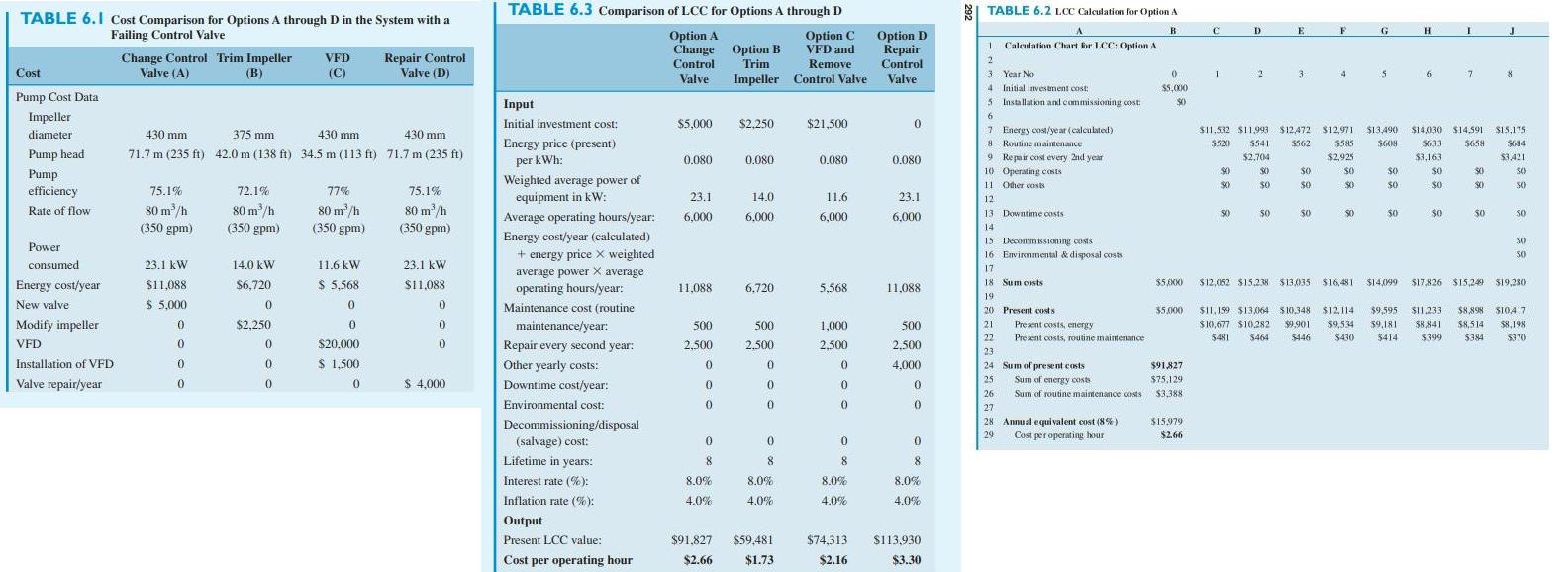

TABLE 6.l Cost Comparison for Options A through D in the System with a TABLE 6.3 Comparison of LCC for Options A through D 8I TABLE 6.2 LCC Calculation for Option A E G Failing Control Valve Option A Change Option B Control Option C VFD and Option D Repair Control 1 Calculation Chart for LCC: Option A Change Control Trim Impeller Valve (A) VFD Repair Control Valve (D) Trim Remove Cost t (B) (C) 3 Year No 4 Initial investment cost: 5 Installation and commissioning cost 2 3 4 6 Valve Impeller Control Valve Valve $5,000 Pump Cost Data Input So Impeller 6 Initial investment cost: $5,000 $2,250 $21,500 7 Energy cost/year (calculated) 8 Routine maintenance 9 Repair cost every 2nd year 10 Operating costS 11 Oher costs diameter 430 mm 375 mm 430 mm 430 mm S11,532 $11,993 $12472 $12,971 $13,490 $14,030 $14,591 S15,175 Energy price (present) per kWh: Weighted average power of equipment in kW: $520 $541 $562 S585 $608 $633 $658 S684 Pump head 71.7 m (235 ft) 42.0 m (138 ft) 34.5 m (113 ft) 71.7 m (235 ft) $2,704 $2,925 $3,163 $3,421 0.080 0.080 0.080 0.080 $0 $0 $0 Pump efficiency $0 $0 S0 $0 $0 $0 75.1% 72.1% 77% 75.1% 23.1 14.0 11.6 23.1 12 80 m/h (350 gpm) 80 m/h (350 gpm) 80 m/h (350 gpm) 80 m'/h (350 gpm) Rate of flow 13 Downtime costs $0 50 $0 $0 Average operating hours/year: 6,000 6.000 6,000 6,000 14 Energy cost/year (calculated) + energy price X weighted 15 Decommissioning costs 16 Envirnmental & disposal costs Power 50 consumed 23.1 kW 14.0 kW 11.6 kW 23.1 kW 17 average power X average $ 5,568 $11,088 $6,720 18 Sum costs $5.000 $12,052 $15,238 $13035 $16,481 S17,826 S15,249 S19,280 $14,(99 Energy cost/year SI1,088 operating hours/year: 11,088 6,720 5,568 11,088 19 $ 5,000 New valve Maintenance cost (routine 20 Present costs $5.000 S11, 159 S13.064 S10.348 S12.114 $9,595 S11.233 $8898 S10417 Modify impeller $2,250 maintenance/year: 500 500 1,000 500 Present costs, energy S10,677 S10.282 9.901 $9,534 21 59,181 $8,841 S8,5 14 S8,198 22 Present costs, routine maintenance $481 $464 5446 $430 $414 $399 $384 $370 VFD $20,000 Repair every second year: 2,500 2,500 2,500 2,500 23 Installation of VFD S 1.500 Other yearly costs: 4,000 24 Sum of pre sent costs $91,827 25 $75,129 Valve repair/year $ 4,000 Downtime cost/year: Sum of energy costs Sum of routine maintenance costs 26 $3,388 Environmental cost: 27 28 Annual equivalent cost (8%) $15,979 Decommissioning/disposal (salvage) cost: Lifetime in years: 29 Cost per operating hour $2.66 8 8 8 8. Interest rate (%): 8.0% 8.0% 8.0% 8.0% Inflation rate (%): 4.0% 4.0% 4.0% 4.0% Output Present LCC value: $91,827 $59,481 $74,313 S113,930 Cost per operating hour $2.66 $1.73 $2.16 $3.30

Step by Step Solution

3.34 Rating (163 Votes )

There are 3 Steps involved in it

Assumptions The current energy price is 008kWh The process is operated for 6000 hoursyear The company has a cost of 500 per year for routine maintenan... View full answer

Get step-by-step solutions from verified subject matter experts