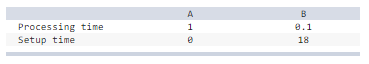

Question: Consider the following two-step process: Processing time 3.1 Setup time 18(a) Suppose units are produced in batches of 14 (Le., after each set of 14

Consider the following two-step process:

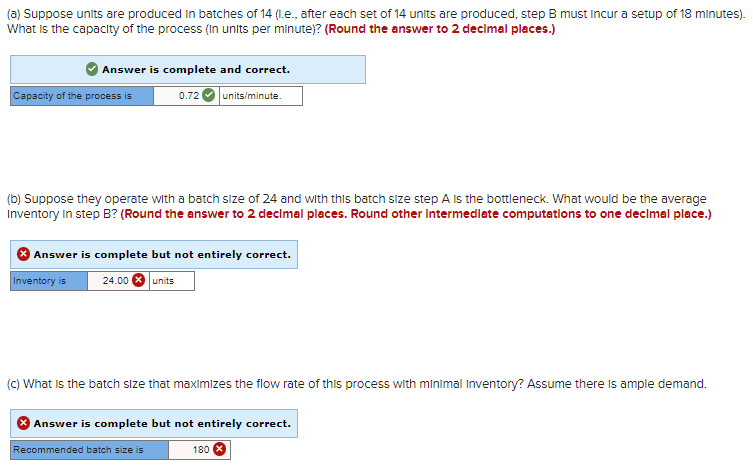

Processing time 3.1 Setup time 18(a) Suppose units are produced in batches of 14 (Le., after each set of 14 units are produced, step B must Incur a setup of 18 minutes). What is the capacity of the process (In units per minute)? (Round the answer to 2 decimal places.) Answer is complete and correct. Capacity of the process is 0.72 units/minute. (b) Suppose they operate with a batch size of 24 and with this batch size step A Is the bottleneck. What would be the average Inventory In step B? (Round the answer to 2 decimal places. Round other Intermediate computations to one decimal place.) Answer is complete but not entirely correct. Inventory is 24.00 % units (c) What is the batch size that maximizes the flow rate of this process with minimal Inventory? Assume there is ample demand. X Answer is complete but not entirely correct. Recommended batch size is 180 X

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts