Question: Could you please complete it within 30mins. I have a time limit. It is really important Hair Plus Inc. has grown exponentially in the last

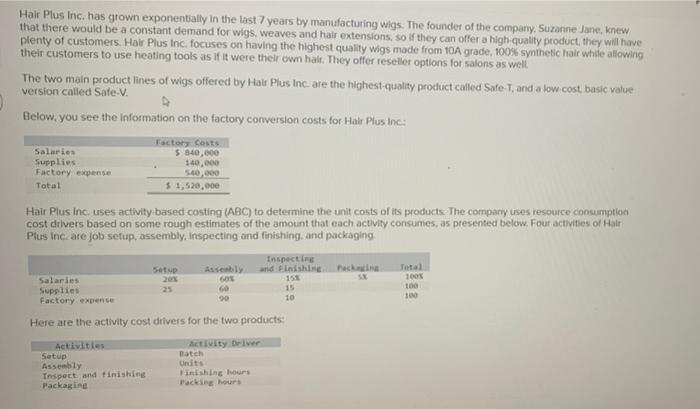

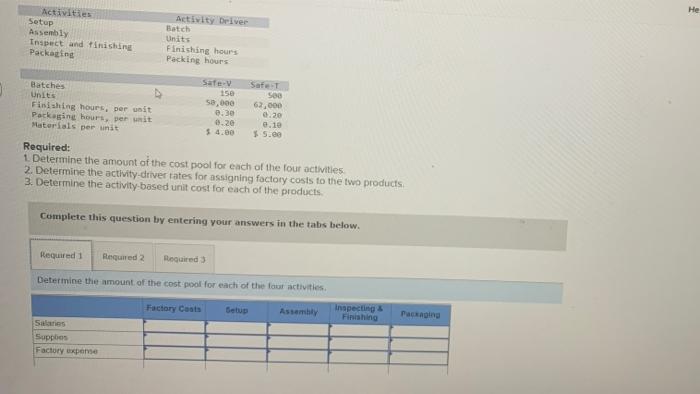

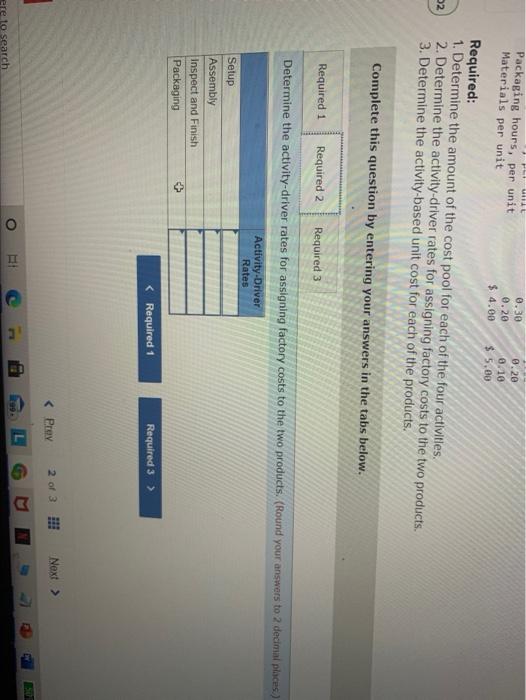

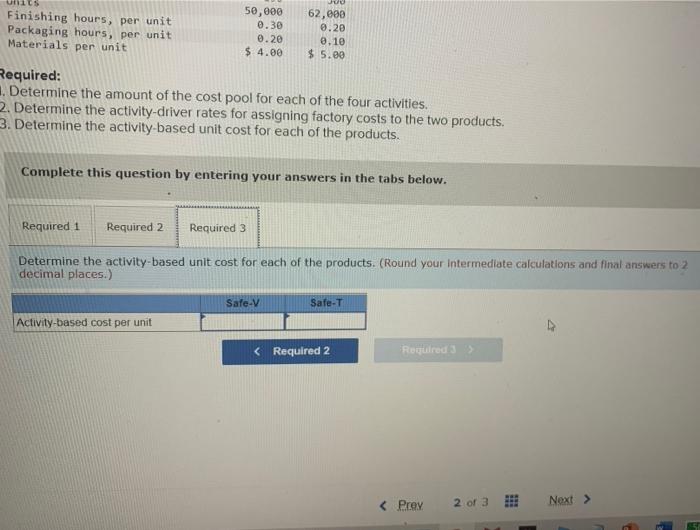

Hair Plus Inc. has grown exponentially in the last 7 years by manufacturing wigs. The founder of the company, Suzanne Jane, knew that there would be a constant demand for wigs, weaves and hair extensions, so if they can offer a high quality product, they will have plenty of customers. Hair Plus Inc. focuses on having the highest quality wigs made from 10A grade, 100% synthetic hair while allowing their customers to use heating tools as if it were their own halt. They offer reseller options for salons as well The two main product lines of wigs offered by Hair Plus Inc. are the highest quality product called Safe-T, and a low cost basic value version called Safe-v. Below, you see the information on the factory conversion costs for Hair Plus Inc Factory Coats Salaries $ 340,000 Factory expense 540,000 $1,520,000 Supplies 140,000 Total Hair Plus Inc. uses activity based costing (ABC) to determine the unit costs of its products. The company uses resource consumption cost delvers based on some rough estimates of the amount that each activity consumes, as presented below. Four activities of Hair Plus Inc. are job setup, assembly, Inspecting and finishing and packaging Inspectie Assembly and finishing Pech Total 153 Supplies 90 Salaries 203 25 15 10 100% 100 100 Factory expense Here are the activity cost drivers for the two products Activities Activity Driver Setup watch Assembly Units Tnsport and finishing Finishing hours Packaging Packing hours He Activities Setup Assembly Inspect and finishing Packaging Activity Driver Batch Units Finishing hours Packing hours Batches Units Flinishing hours, per unit Packaging hours, per unit Materials per unit Safe.v ise 58,000 2.30 13.20 $4.00 Safet 500 62,000 0.30 0.10 5.ee Required: 1. Determine the amount of the cost pool for ench of the four activities 2. Determine the activity-driver rates for assigning factory costs to the two products 3. Determine the activity based unit cost for each of the products, Complete this question by entering your answers in the tabs below. Required Required 2 Required Determine the amount of the cost pool for each of the four activities Factory Coats Getup Assembly inspecting Finishing Packaging Sales Supplies Factory expense Packaging hours, per unit Materials per unit 0.30 0.20 $ 4.00 0.20 0.10 $ 5.00 Required: 1. Determine the amount of the cost pool for each of the four activities. 2. Determine the activity-driver rates for assigning factory costs to the two products. 3. Determine the activity-based unit cost for each of the products. 2 Complete this question by entering your answers in the tabs below. Required 1 Required 2 Required 3 Determine the activity-driver rates for assigning factory costs to the two products. (Round your answers to 2 decimal places.) Activity Driver Rates Setup Assembly Inspect and Finish Packaging + 1 o f ere to search Finishing hours, per unit Packaging hours, per unit Materials per unit 50,000 0.30 0.20 $ 4.00 62,800 0.20 8.10 $ 5.00 Required: Determine the amount of the cost pool for each of the four activities, 2. Determine the activity-driver rates for assigning factory costs to the two products. 3. Determine the activity-based unit cost for each of the products. Complete this question by entering your answers in the tabs below. Required 1 Required 2 Required 3 Determine the activity-based unit cost for each of the products. (Round your intermediate calculations and final answers to 2 decimal places.) Safe-V Safe-T Activity-based cost per unit

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts