Question: Course name is Capstone Project in Supply chain management program. Case Study 2 - Forecast inaccuracy and finished goods stockouts at MKLIT Manufacturing Co. Company

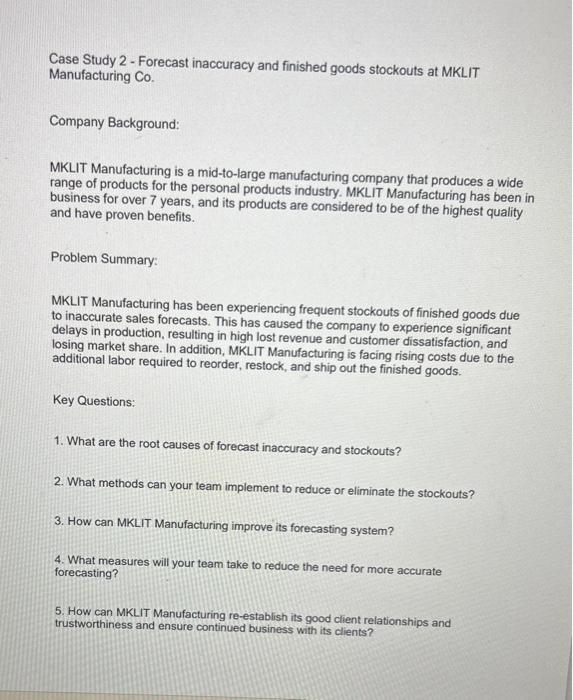

Case Study 2 - Forecast inaccuracy and finished goods stockouts at MKLIT Manufacturing Co. Company Background: MKLIT Manufacturing is a mid-to-large manufacturing company that produces a wide range of products for the personal products industry. MKLIT Manufacturing has been in business for over 7 years, and its products are considered to be of the highest quality and have proven benefits. Problem Summary: MKLIT Manufacturing has been experiencing frequent stockouts of finished goods due to inaccurate sales forecasts. This has caused the company to experience significant delays in production, resulting in high lost revenue and customer dissatisfaction, and losing market share. In addition, MKLIT Manufacturing is facing rising costs due to the additional labor required to reorder, restock, and ship out the finished goods. Key Questions: 1. What are the root causes of forecast inaccuracy and stockouts? 2. What methods can your team implement to reduce or eliminate the stockouts? 3. How can MKLIT Manufacturing improve its forecasting system? 4. What measures will your team take to reduce the need for more accurate forecasting? 5. How can MKLIT Manufacturing re-establish its good client relationships and trustworthiness and ensure continued business with its clients

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts