Question: Create a flowchart for a process from the following image - 20.1333 Day Day 11 30 1 21 Application of Knowledge Congratulations! You've just been

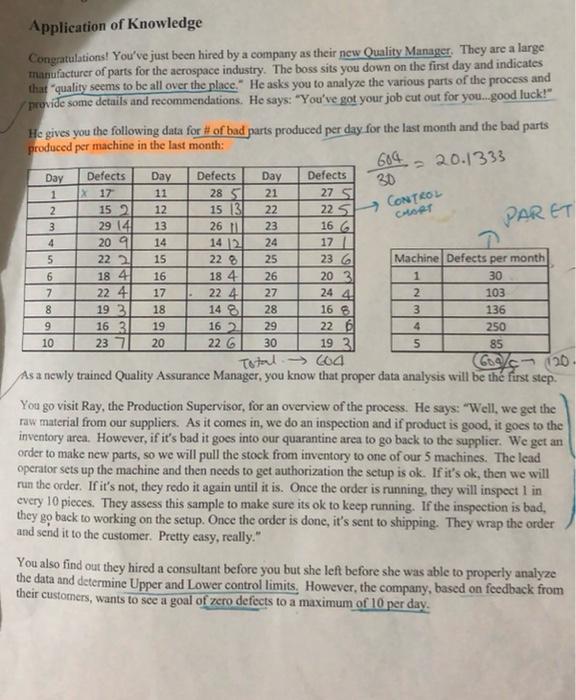

- 20.1333 Day Day 11 30 1 21 Application of Knowledge Congratulations! You've just been hired by a company as their new Quality Manager. They are a large manufacturer of parts for the aerospace industry. The boss sits you down on the first day and indicates that quality seems to be all over the place." He asks you to analyze the various parts of the process and provide some details and recommendations. He says: "You've got your job cut out for you...good luck!" He gives you the following data for # of bad parts produced per day for the last month and the bad parts produced per machine in the last month: 604 Defects Defects Day Defects X 17 285 27 S 159 15 13 29 14 26 16 A 20 a 14 12 17 | 222 22 8 23 Machine Defects per month 18 4 18 4 20 3 224 224 24 4 193 14 8 16 8 16 3 226 10 20 226 30 193 85 Total. 604 As a newly trained Quality Assurance Manager, you know that proper data analysis will be the first step. 2 12 22 225 CONTROL CHART PARET 3 13 23 4 14 24 5 15 25 6 16 26 1 30 7 17 27 2 103 8 18 28 3 136 9 19 16 2 29 4 250 237 5 - 20 You go visit Ray, the Production Supervisor, for an overview of the process. He says: "Well, we get the raw material from our suppliers. As it comes in, we do an inspection and if product is good, it goes to the inventory area. However, if it's bad it goes into our quarantine area to go back to the supplier. We get an order to make new parts, so we will pull the stock from inventory to one of our 5 machines. The lead operator sets up the machine and then needs to get authorization the setup is ok. If it's ok, then we will run the order. If it's not, they redo it again until it is. Once the order is running, they will inspect 1 in every 10 pieces. They assess this sample to make sure its ok to keep running. If the inspection is bad, they go back to working on the setup. Once the order is done, it's sent to shipping. They wrap the order and send it to the customer. Pretty easy, really." You also find out they hired a consultant before you but she left before she was able to properly analyze the data and determine Upper and Lower control limits. However, the company, based on feedback from their customers, wants to see a goal of zero defects to a maximum of 10 per day

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts