Question: Create a maximum profit production plan for the next week for the three LEGO furniture products: TABLES (made of 2 Large LEGOs and 2 Small

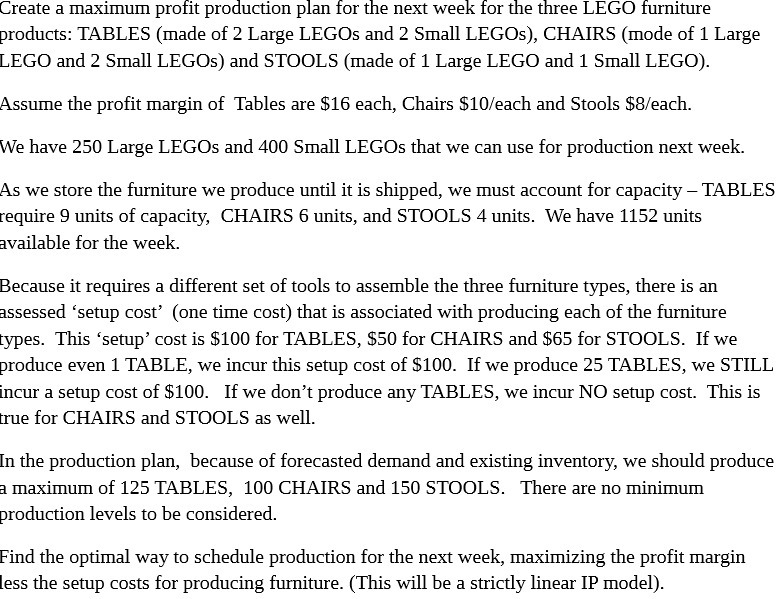

Create a maximum profit production plan for the next week for the three LEGO furniture products: TABLES (made of 2 Large LEGOs and 2 Small LEGOs], CHAIRS (mode of 1 Large LEGO and 2 Small LEGOs) and STOOLS (made of 1 Large LEGO and 1 Small LEGO). Assume the prot margin of Tables are $15 each, Chairs $10r'each and Stools $Sfeach. We have 250 Large LEGOs and 400 Small LEGOs that we can use for production next week. As we store the furniture we produce until it is shipped, we must account for capacity TABLES require 9 units of capacity, CHAIRS 6 units, and STOOLS 4 units. We have 1152 units available for the week. Because it requires a different set of tools to assemble the three fumiture types, there is an assessed 'setup cost' (one time cost) that is associated with producing each of the furniture types. This 'setup' cost is $100 for TABLES, $50 for CHAIRS and $65 for STOOLS. If we produce even 1 TABLE, we incur this setup cost of $100. If we produce 25 TABLES, we STILL incur a setup cost of $100. If we don't produce any TABLES, we incur NO setup cost. This is true for CHAIRS and STOOLS as well. In the production plan, because of forecasted demand and existing inventory, we should produce a maximum of 125 TABLES, 100 CHAIRS and 150 STOOLS. There are no minimum production levels to be considered. Find the optimal way to schedule production for the next week, maximizing the profit margin less the setup costs for producing furniture. (This will be a strictly linear IP model)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts