Question: d ss I need to answer part 2 Period 1 2 3 5 6 7 8 9 10 11 data Year Demand 2007 2662 2008

dss

dss

I need to answer part 2

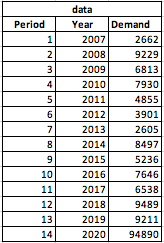

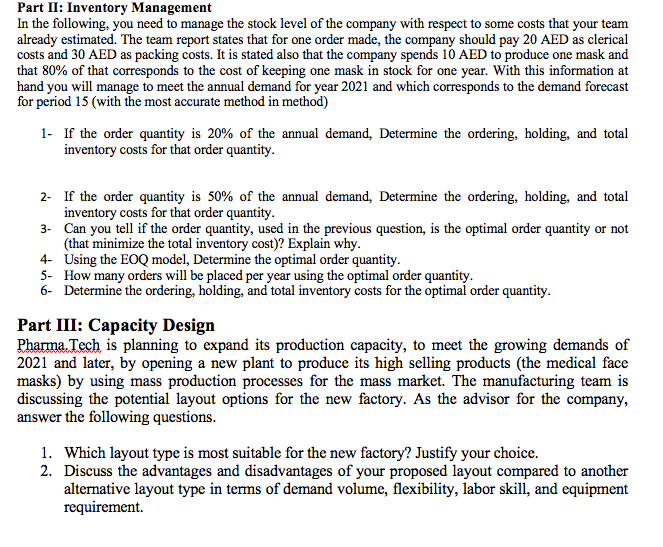

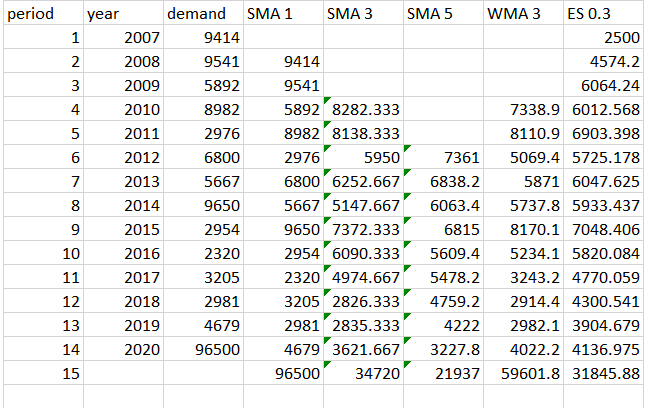

Period 1 2 3 5 6 7 8 9 10 11 data Year Demand 2007 2662 2008 9229 2009 6813 2010 7930 2011 4855 2012 3901 2013 2605 2014 8497 2015 5236 2016 7646 2017 6538 2018 9489 2019 9211 2020 94890 12 13 14 Part II: Inventory Management In the following, you need to manage the stock level of the company with respect to some costs that your team already estimated. The team report states that for one order made, the company should pay 20 AED as clerical costs and 30 AED as packing costs. It is stated also that the company spends 10 AED to produce one mask and that 80% of that corresponds to the cost of keeping one mask in stock for one year. With this information at hand you will manage to meet the annual demand for year 2021 and which corresponds to the demand forecast for period 15 (with the most accurate method in method) 1. If the order quantity is 20% of the annual demand, Determine the ordering, holding, and total inventory costs for that order quantity. 2- If the order quantity is 50% of the annual demand, Determine the ordering, holding, and total inventory costs for that order quantity. 3. Can you tell if the order quantity, used in the previous question, is the optimal order quantity or not (that minimize the total inventory cost)? Explain why. 4. Using the EOQ model, Determine the optimal order quantity. 5. How many orders will be placed per year using the optimal order quantity. 6- Determine the ordering, holding, and total inventory costs for the optimal order quantity. Part III: Capacity Design Pharma.Tech is planning to expand its production capacity, to meet the growing demands of 2021 and later, by opening a new plant to produce its high selling products (the medical face masks) by using mass production processes for the mass market. The manufacturing team is discussing the potential layout options for the new factory. As the advisor for the company, answer the following questions. 1. Which layout type is most suitable for the new factory? Justify your choice. 2. Discuss the advantages and disadvantages of your proposed layout compared to another alternative layout type in terms of demand volume, flexibility, labor skill, and equipment requirement. period year demand SMA 1 SMA 3 SMA 5 WMA 3 ES 0.3 1 2007 9414 2500 2 2008 9541 9414 4574.2 3 2009 5892 9541 6064.24 4 2010 8982 5892 8282.333 7338.9 6012.568 5 2011 2976 8982 8138.333 8110.9 6903.398 6 2012 6800 2976 5950 7361 5069.4 5725.178 7 2013 5667 6800 6252.667 6838.2 5871 6047.625 8 2014 9650 5667 5147.667 6063.4 5737.8 5933.437 2015 2954 9650 7372.333 6815 8170.1 7048.406 10 2016 2320 2954 6090.333 5609.4 5234.1 5820.084 11 2017 3205 2320 4974.667 5478.2 3243.2 4770.059 12 2018 2981 3205 2826.333 4759.2 2914.4 4300.541 13 2019 4679 2981 2835.333 4222 2982.1 3904.679 14 2020 96500 4679 3621.667 3227.8 4022.2 4136.975 15 96500 34720 21937 59601.8 31845.88 9Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock