Question: Determine the optimal fill time for a simple casting with dimensions 1 in . 6 in . 8 in . The part is to be

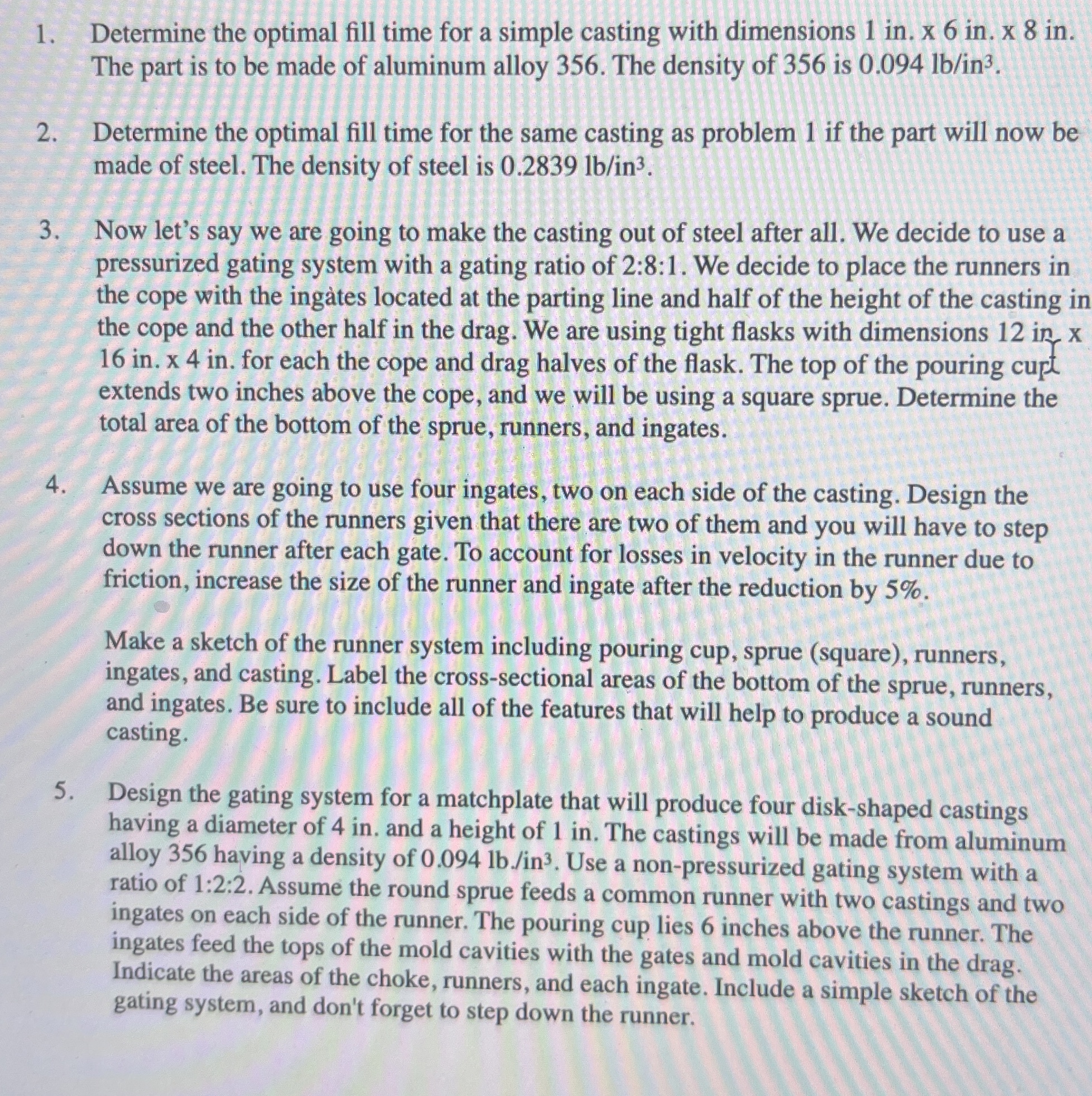

Determine the optimal fill time for a simple casting with dimensions in in in

The part is to be made of aluminum alloy The density of is

Determine the optimal fill time for the same casting as problem if the part will now be

made of steel. The density of steel is

Now let's say we are going to make the casting out of steel after all. We decide to use a

pressurized gating system with a gating ratio of :: We decide to place the runners in

the cope with the ingates located at the parting line and half of the height of the casting in

the cope and the other half in the drag. We are using tight flasks with dimensions in

x in for each the cope and drag halves of the flask. The top of the pouring cur

extends two inches above the cope, and we will be using a square sprue. Determine the

total area of the bottom of the sprue, runners, and ingates.

Assume we are going to use four ingates, two on each side of the casting. Design the

cross sections of the runners given that there are two of them and you will have to step

down the runner after each gate. To account for losses in velocity in the runner due to

friction, increase the size of the runner and ingate after the reduction by

Make a sketch of the runner system including pouring cup, sprue square runners,

ingates, and casting. Label the crosssectional areas of the bottom of the sprue, runners,

and ingates. Be sure to include all of the features that will help to produce a sound

casting.

Design the gating system for a matchplate that will produce four diskshaped castings

having a diameter of in and a height of in The castings will be made from aluminum

alloy having a density of Use a nonpressurized gating system with a

ratio of :: Assume the round sprue feeds a common runner with two castings and two

ingates on each side of the runner. The pouring cup lies inches above the runner. The

ingates feed the tops of the mold cavities with the gates and mold cavities in the drag.

Indicate the areas of the choke, runners, and each ingate. Include a simple sketch of the

gating system, and don't forget to step down the runner.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock