Question: Problem 1 : Design a Casting Mold An aluminum workpiece shown below is to be manufactured by sand casting ( can assume part to be

Problem : Design a Casting Mold

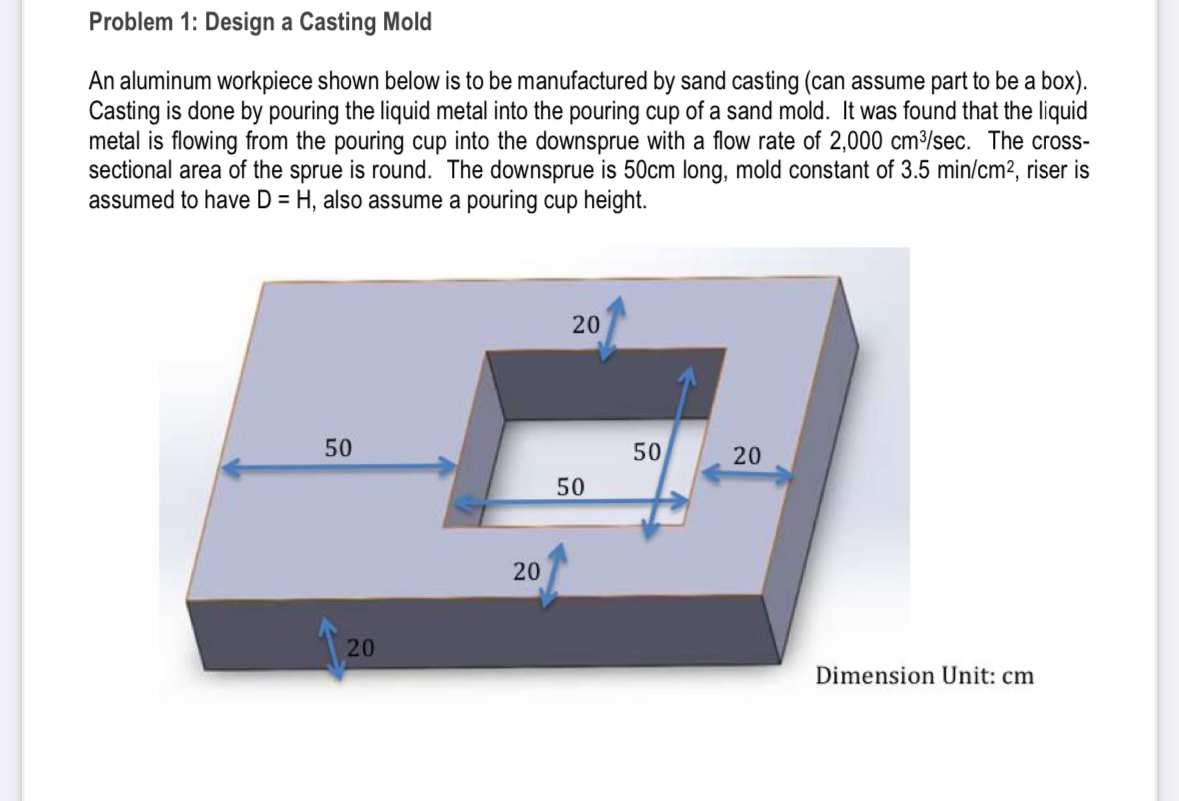

An aluminum workpiece shown below is to be manufactured by sand casting can assume part to be a box Casting is done by pouring the liquid metal into the pouring cup of a sand mold. It was found that the liquid metal is flowing from the pouring cup into the downsprue with a flow rate of The crosssectional area of the sprue is round. The downsprue is cm long, mold constant of riser is assumed to have also assume a pouring cup height.

ion Unit: cm

Determine the following:

Material Properties Used

a Density

b Melt Temperature

c Thermal Capacitance for Solid Material

d Thermal Capacitance for Liquid Material JkgC CL

e Assumed Initial Temperature

f Viscosity kgmms

g Heat of Fusion Jkg Hfusion

h Pouring temperature make necessary assumptions

Sand Used

Part oversize to allow for shrinkage or part pattern, Volume, and Surface Area, show calculations

Solidification time for Part, with mold constant, and exponent

Riser Dimensions, Volume, and Surface Area,

D

Ariser:

Expected solidification time of riser, triser. show calculations

triser

Dimensions of downsprue and gate. Design for no turbulence.

Sprue entrance diameter,

Sprue Exit,

Total molten metal volume show calculations

Mold Fill time

Selected furnace to melt the aluminum with calculation of proper Heat required, Hshow calculations H

Draw and Label Steps for Sand Casting and show mold design sketch with all parts labeled where is the Parting Line?:

Problem : Design a Casting Mold

An aluminum workpiece shown below is to be manufactured by sand casting can assume part to be a box Casting is done by pouring the liquid metal into the pouring cup of a sand mold. It was found that the liquid metal is flowing from the pouring cup into the downsprue with a flow rate of The crosssectional area of the sprue is round. The downsprue is cm long, mold constant of riser is assumed to have also assume a pouring cup height.

ion Unit: cm

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock