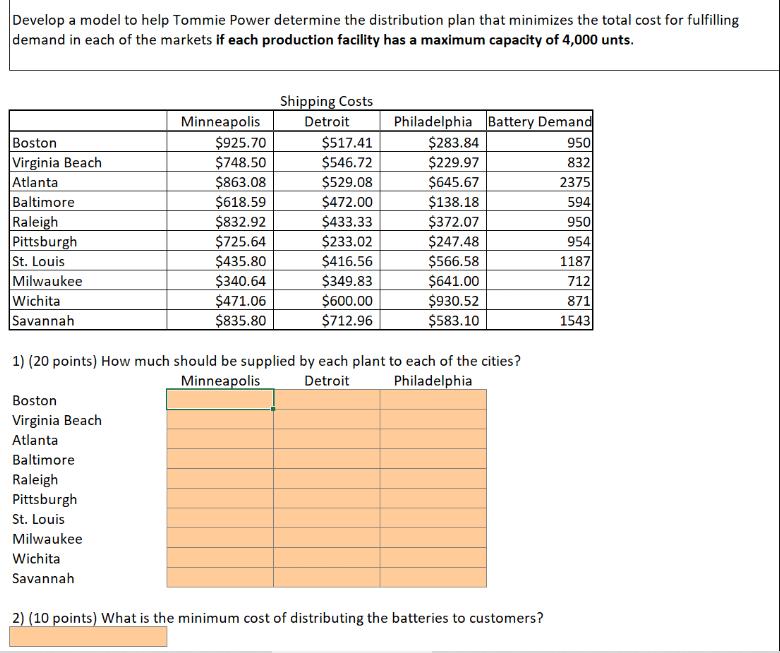

Question: Develop a model to help Tommie Power determine the distribution plan that minimizes the total cost for fulfilling demand in each of the markets

Develop a model to help Tommie Power determine the distribution plan that minimizes the total cost for fulfilling demand in each of the markets if each production facility has a maximum capacity of 4,000 unts. Boston Virginia Beach Atlanta Baltimore Raleigh Pittsburgh St. Louis Milwaukee Wichita Savannah Boston Virginia Beach Atlanta Minneapolis $925.70 $748.50 $863.08 $618.59 $832.92 $725.64 $435.80 $340.64 $471.06 $835.80 Baltimore Raleigh Pittsburgh St. Louis Milwaukee Wichita Savannah Shipping Costs Detroit $517.41 $546.72 $529.08 $472.00 $433.33 $233.02 $416.56 $349.83 $600.00 $712.96 Philadelphia Battery Demand 950 832 2375 594 950 954 1187 712 871 1543 $283.84 $229.97 $645.67 $138.18 $372.07 $247.48 $566.58 $641.00 1) (20 points) How much should be supplied by each plant to each of the cities? Minneapolis Detroit Philadelphia $930.52 $583.10 2) (10 points) What is the minimum cost of distributing the batteries to customers?

Step by Step Solution

3.46 Rating (146 Votes )

There are 3 Steps involved in it

To develop a model for Tommie Power we can use linear programming to minimize total distri... View full answer

Get step-by-step solutions from verified subject matter experts