Question: df 2 / 6 100% + 2. An assembly line for a component with many tasks has been designed following two different line balancing algorithms.

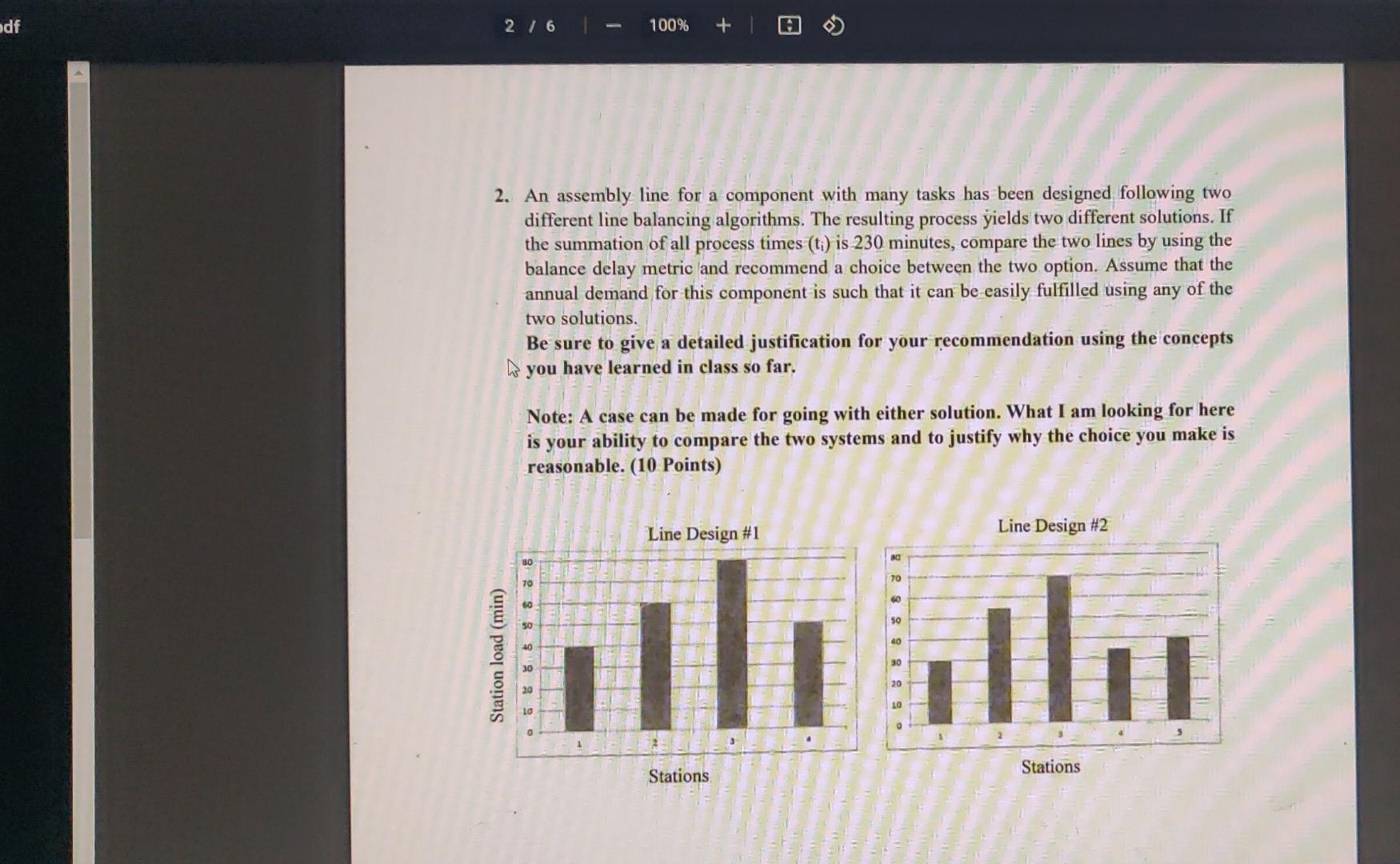

df 2 / 6 100% + 2. An assembly line for a component with many tasks has been designed following two different line balancing algorithms. The resulting process yields two different solutions. If the summation of all process times (ti) is 230 minutes, compare the two lines by using the balance delay metric and recommend a choice between the two option. Assume that the annual demand for this component is such that it can be easily fulfilled using any of the two solutions. Be sure to give a detailed justification for your recommendation using the concepts w you have learned in class so far. Note: A case can be made for going with either solution. What I am looking for here is your ability to compare the two systems and to justify why the choice you make is reasonable. (10 Points) Line Design #1 Line Design #2 38 TO 60 50 40 Station load (min) ili ulu 30 I a & 5 20 Stations Stations

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock