Question: Discussion Assignment: Review the learning curve example for ABC Corporation on pages 347-348. Question 1: (Individual Contribution in team discussion area - due by Sunday

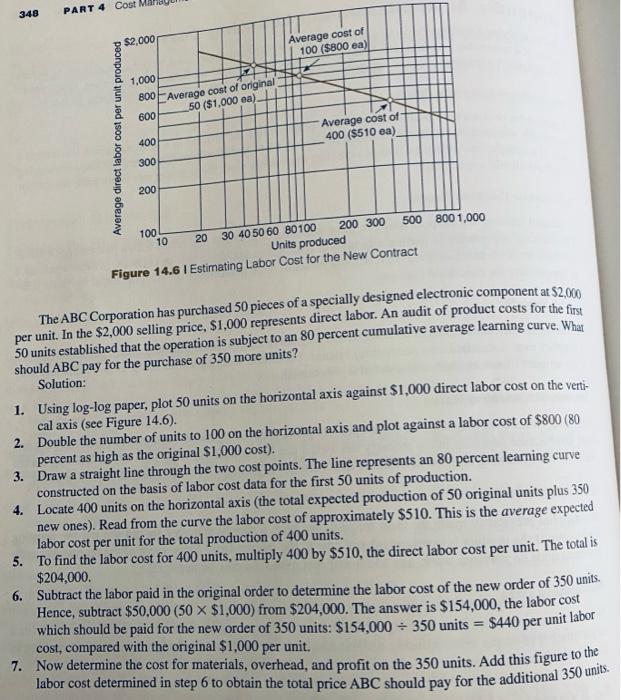

Discussion Assignment: Review the learning curve example for ABC Corporation on pages 347-348. Question 1: (Individual Contribution in team discussion area - due by Sunday 11/22. 9pm.) Instead of an 80% learning curve, the supplier believes that either a 90% or 95% learning curve will be more indicative of what will occur in the future starting at unit 51). What would be the unit cost of labor for the next 350 units using a 90% leaming curve and a 95% leaming curve? Show calculations that use the fomulas that are provided in the posted learning curve articles. Question 2: (Individual Contribution in team discussion area - due by Sunday 11:22. Opm.) What would be the total price ABC should pay for the 350 units for an som learning curve for labor, for an 90% learning curve and for an 95% learning curve for labor! What difference is this between the two assumptions of leaming curves? Question 3: (Individual Contribution in team discussion area - due by Sunday: 1129pm.) What suggestions should ABC make to the supplier in order for the supplier to incur cost reductions at the 80% learning eurve level? 348 PART 4 Cost MI $2,000 Average cost of 100 ($800 ea) 1.000 800 Average cost of orginal 50 ($1,000 ea) 600 Average direct labor cost per unit produced Average cost of 400 ($510 ea) 400 300 200 100 10 20 30 40 50 60 80100 200 300 500 800 1,000 Units produced Figure 14.6 I Estimating Labor Cost for the New Contract The ABC Corporation has purchased 50 pieces of a specially designed electronic component at $2,000 per unit . In the $2,000 selling price, $1,000 represents direct labor. An audit of product costs for the first 50 units established that the operation is subject to an 80 percent cumulative average learning curve. What should ABC pay for the purchase of 350 more units? Solution: 1. Using log-log paper, plot 50 units on the horizontal axis against $1,000 direct labor cost on the verti- cal axis (see Figure 14.6). 2. Double the number of units to 100 on the horizontal axis and plot against a labor cost of $800 (80 percent as high as the original $1,000 cost). 3. Draw a straight line through the two cost points. The line represents an 80 percent learning curve constructed on the basis of labor cost data for the first 50 units of production. 4. Locate 400 units on the horizontal axis (the total expected production of 50 original units plus 350 new ones). Read from the curve the labor cost of approximately $510. This is the average expected labor cost per unit for the total production of 400 units. 5. To find the labor cost for 400 units, multiply 400 by $510, the direct labor cost per unit. The total is $204,000. 6. Subtract the labor paid in the original order to determine the labor cost of the new order of 350 units. Hence, subtract $50,000 (50 x $1,000) from $204,000. The answer is $154,000, the labor cost which should be paid for the new order of 350 units: $154,000 + 350 units = $440 per unit labor cost, compared with the original $1,000 per unit. 7. Now determine the cost for materials, overhead, and profit on the 350 units. Add this figure to the labor cost determined in step 6 to obtain the total price ABC should pay for the additional 350 units