Question: DONT ANSWER IF YOU'RE NOT GOING TO DO THE EXCEL SOLUTION The table below summarizes the hours of machining, grinding, and assembly required by each

DONT ANSWER IF YOU'RE NOT GOING TO DO THE EXCEL SOLUTION

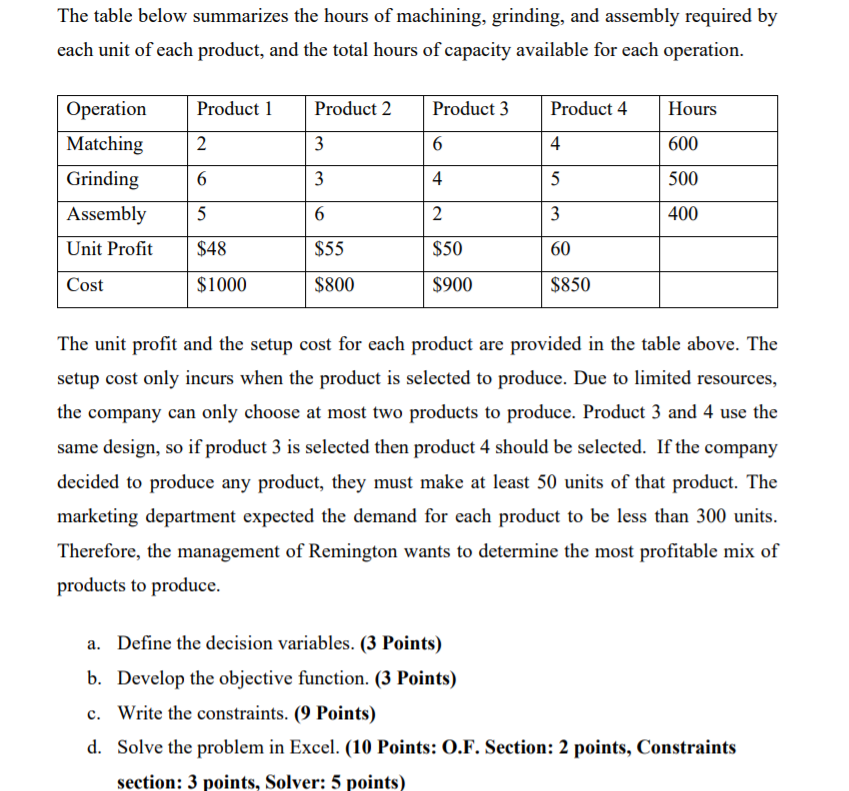

The table below summarizes the hours of machining, grinding, and assembly required by each unit of each product, and the total hours of capacity available for each operation. Product 1 Product 2 Product 3 Product 4 Hours 2 3 6 4 600 Operation Matching Grinding Assembly Unit Profit 6 3 4 5 500 5 6 2 3 400 $48 $55 $50 60 Cost $1000 $800 $900 $850 The unit profit and the setup cost for each product are provided in the table above. The setup cost only incurs when the product is selected to produce. Due to limited resources, the company can only choose at most two products to produce. Product 3 and 4 use the same design, so if product 3 is selected then product 4 should be selected. If the company decided to produce any product, they must make at least 50 units of that product. The marketing department expected the demand for each product to be less than 300 units. Therefore, the management of Remington wants to determine the most profitable mix of products to produce. a. Define the decision variables. (3 Points) b. Develop the objective function. (3 Points) c. Write the constraints. (9 Points) d. Solve the problem in Excel. (10 Points: 0.F. Section: 2 points, Constraints section: 3 points, Solver: 5 points)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock