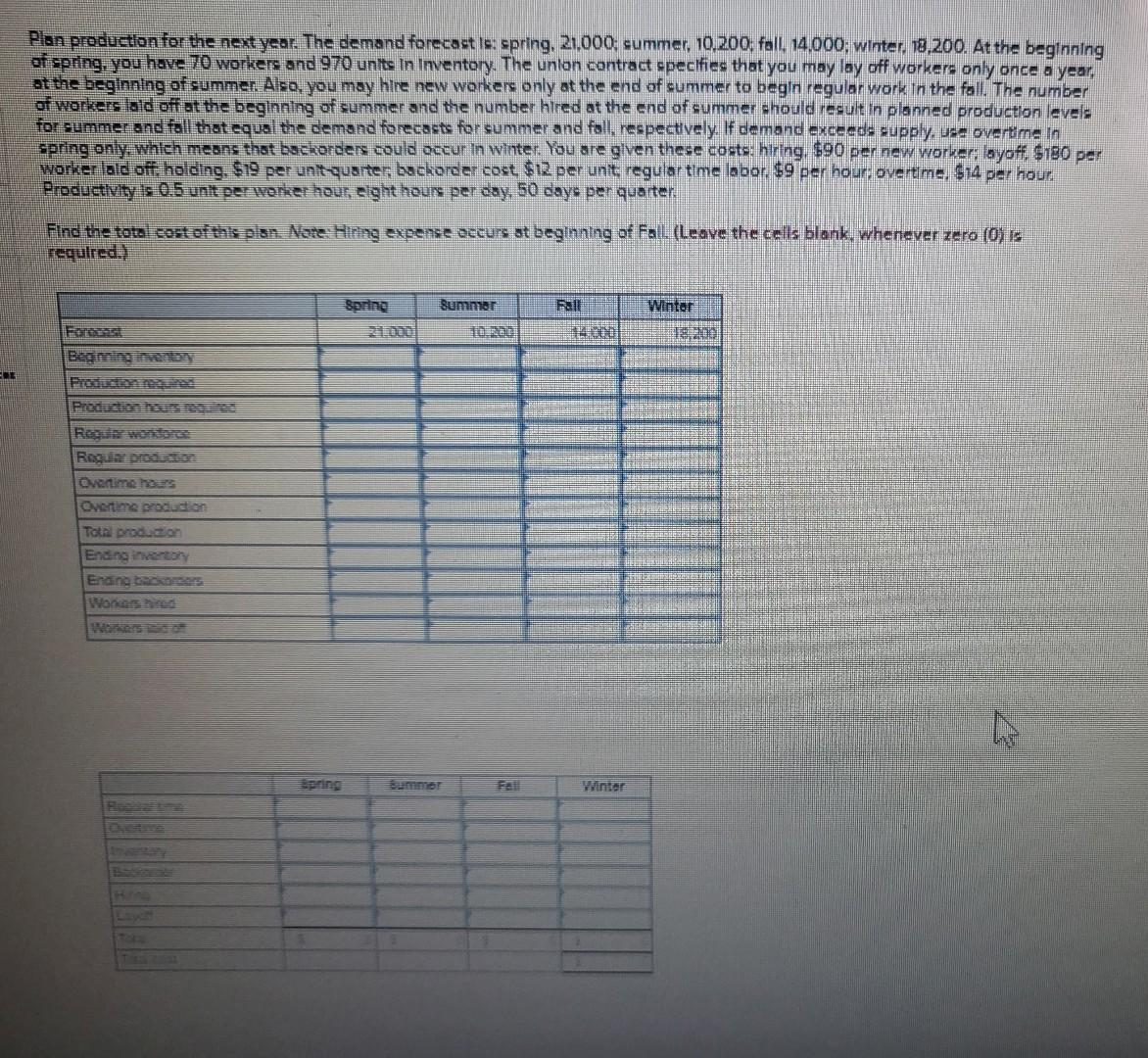

Question: E Plan production for the next year. The demand forecast Is: spring, 21,000; summer, 10,200, fall, 14,000; winter, 18,200. At the beginning of spring, you

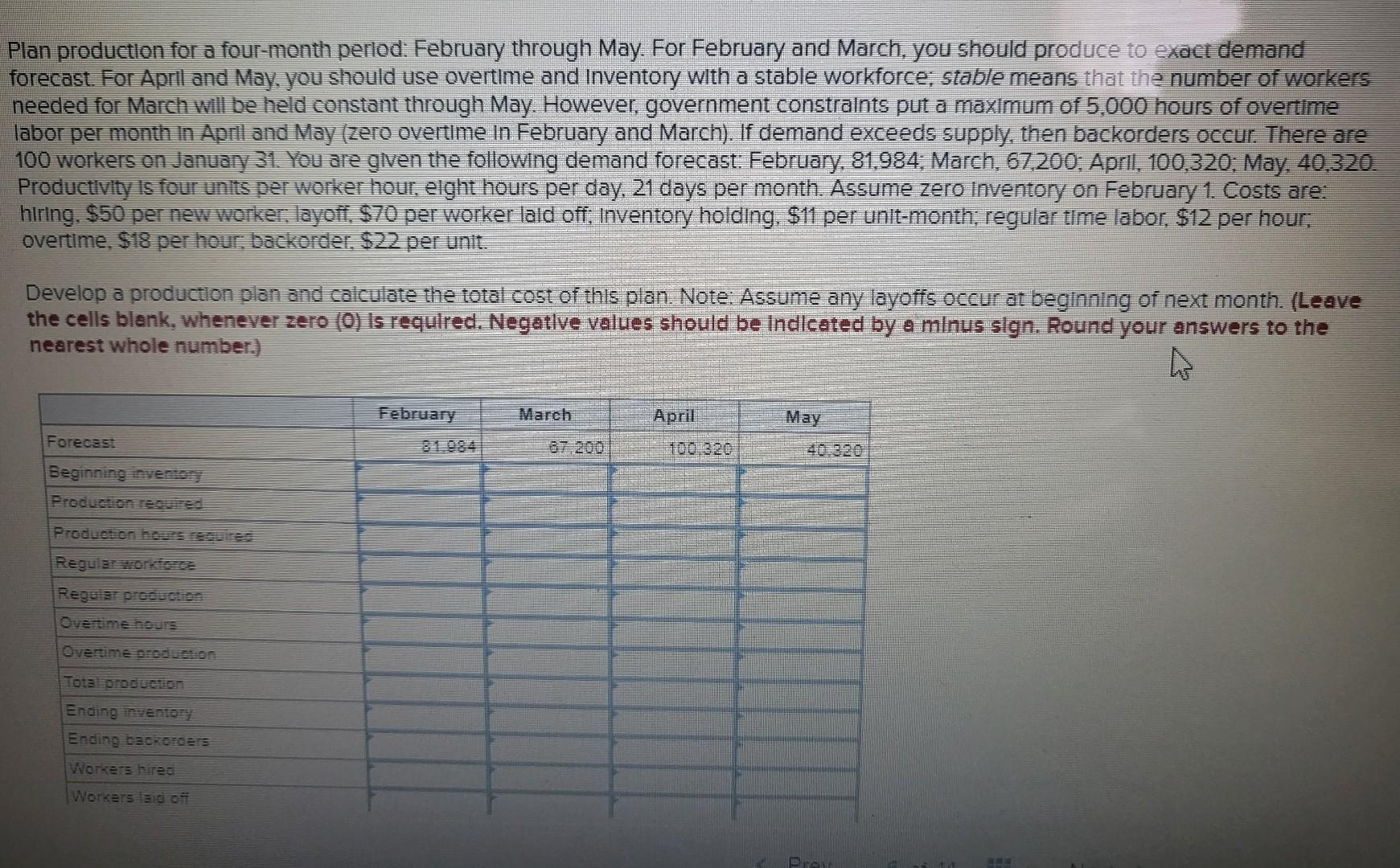

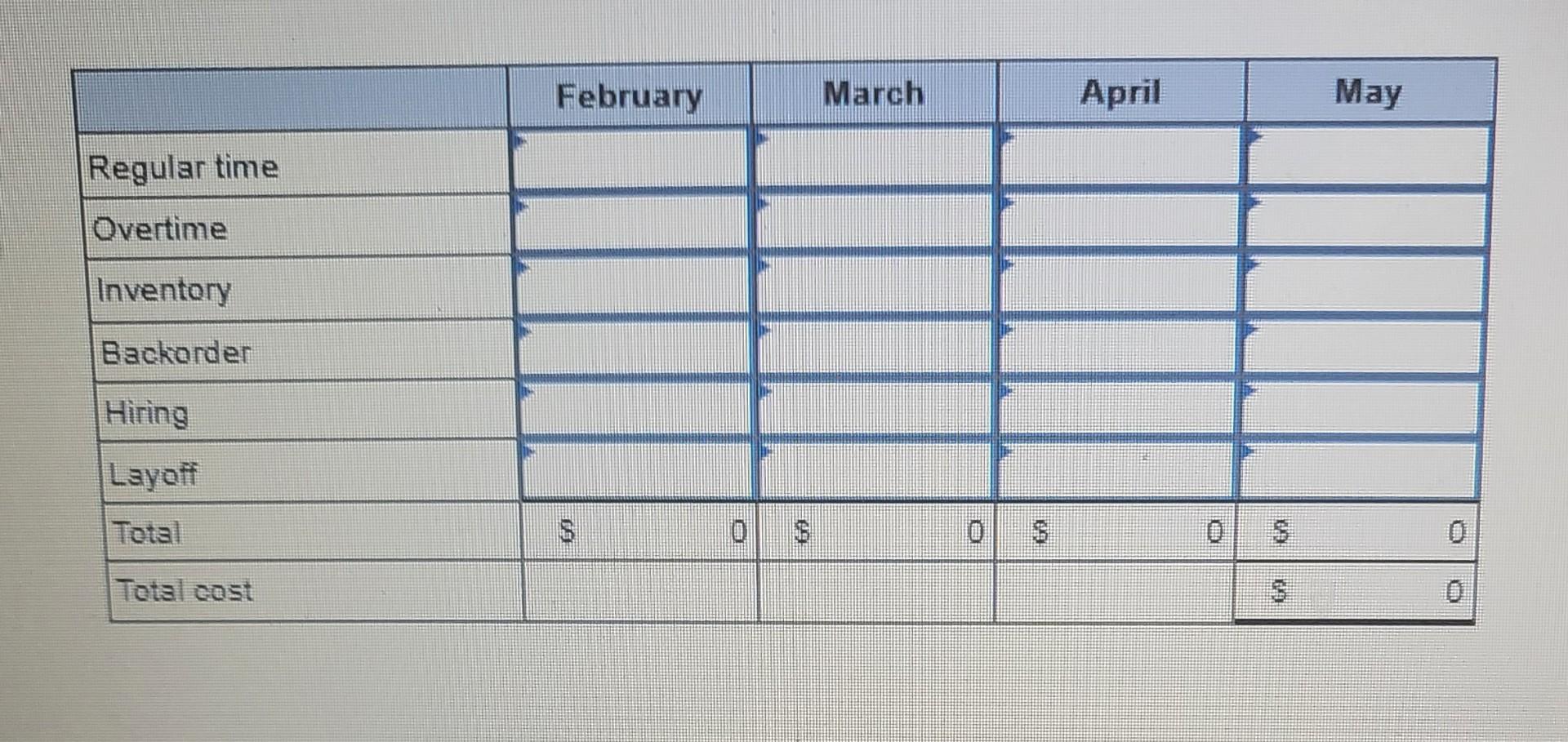

E Plan production for the next year. The demand forecast Is: spring, 21,000; summer, 10,200, fall, 14,000; winter, 18,200. At the beginning of spring, you have 70 workers and 970 units in Inventory. The union contract specifies that you may lay off workers only once a year, at the beginning of summer. Also, you may hire new workers only at the end of summer to begin regular work in the fall. The number of workers laid off at the beginning of summer and the number hired at the end of summer should result in planned production levels for summer and fall that equal the demand forecasts for summer and fall, respectively. If demand exceeds supply, use overtime in spring only, which means that backorders could occur in winter. You are given these costs: hiring, $90 per new worker; layoff, $180 per worker laid off, holding. $19 per unit-quarter; backorder cost $12 per unit regular time labor, $9 per hour; overtime, $14 per hour. Productivity is 0.5 unit per worker hour, eight hours per day, 50 days per quarter. Find the total cost of this plan. Note: Hiring expense accurs at beginning of Fall. (Leave the cells blank, whenever zero (0) is required.) Forecast Production required Production hours required Regular workforce Regular production Overtime hours Overtime production Total production Ending inventory Ending backorders Workers hired Spring Summer Summer 10.200 Fall 14.000 Winter Plan production for a four-month perlod: February through May. For February and March, you should produce to exact demand forecast. For April and May, you should use overtime and Inventory with a stable workforce, stable means that the number of workers needed for March will be held constant through May. However, government constraints put a maximum of 5,000 hours of overtime labor per month In April and May (zero overtime in February and March). If demand exceeds supply, then backorders occur. There are 100 workers on January 31. You are given the following demand forecast: February, 81,984; March, 67,200, April, 100,320; May, 40,320. Productivity is four units per worker hour, eight hours per day, 21 days per month. Assume zero Inventory on February 1. Costs are: hiring, $50 per new worker, layoff, $70 per worker laid off, Inventory holding, $11 per unit-month; regular time labor, $12 per hour; overtime, $18 per hour, backorder. $22 per unit. Develop a production plan and calculate the total cost of this plan. Note: Assume any layoffs occur at beginning of next month. (Leave the cells blank, whenever zero (0) Is required. Negative values should be indicated by a minus sign. Round your answers to the nearest whole number.) 4 Forecast Beginning inventory Production required Production hours required Regular workforce Regular production Overtime hours Overtime production Total production Ending inventory Ending backorders Workers hired Workers laid off February March 37 200 April May Prev 855 Regular time Overtime Inventory Backorder Hiring Layoff Total Total cost February $ March DO April 0 XXXX CO May C CHFO

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock