Question: Example 3 DETERMINING NET REQUIREMENTS Speaker Kits, Inc., developed a product structure from a bill of material in Example 1. Example 2 devel- oped a

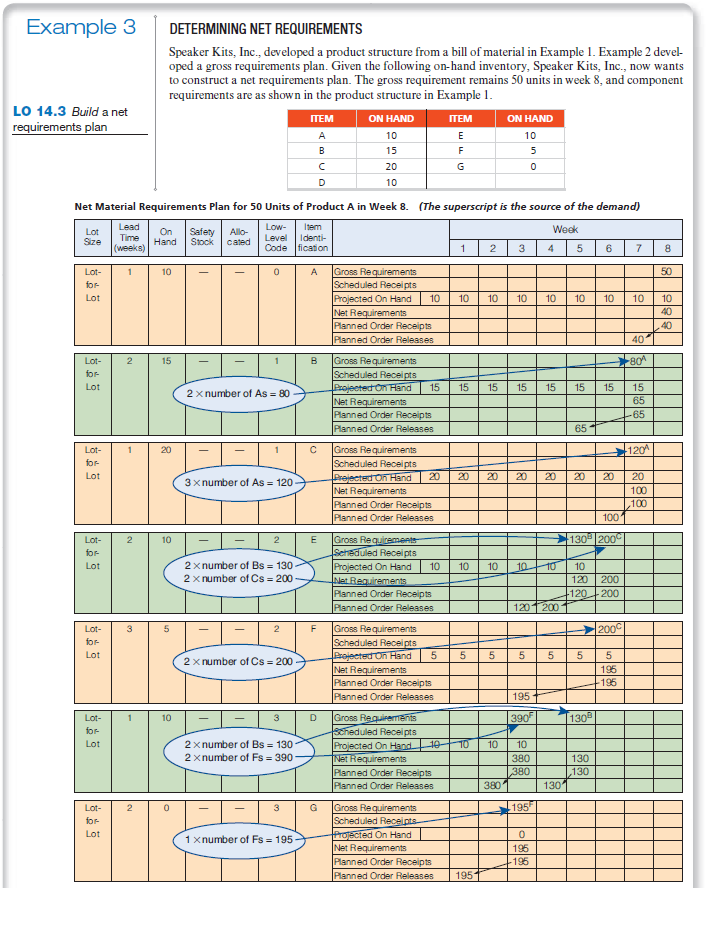

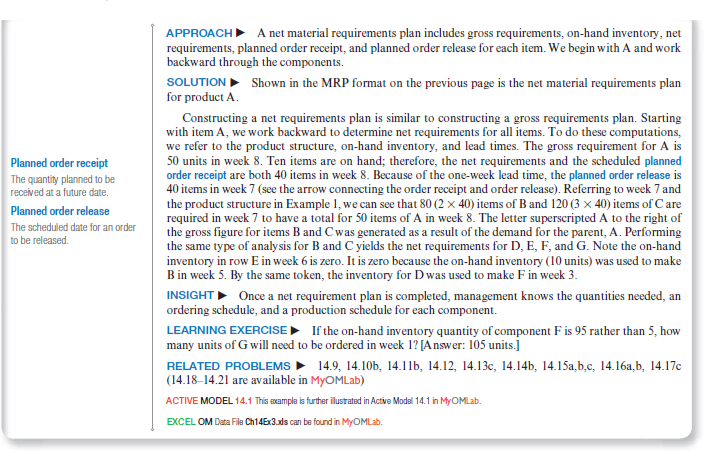

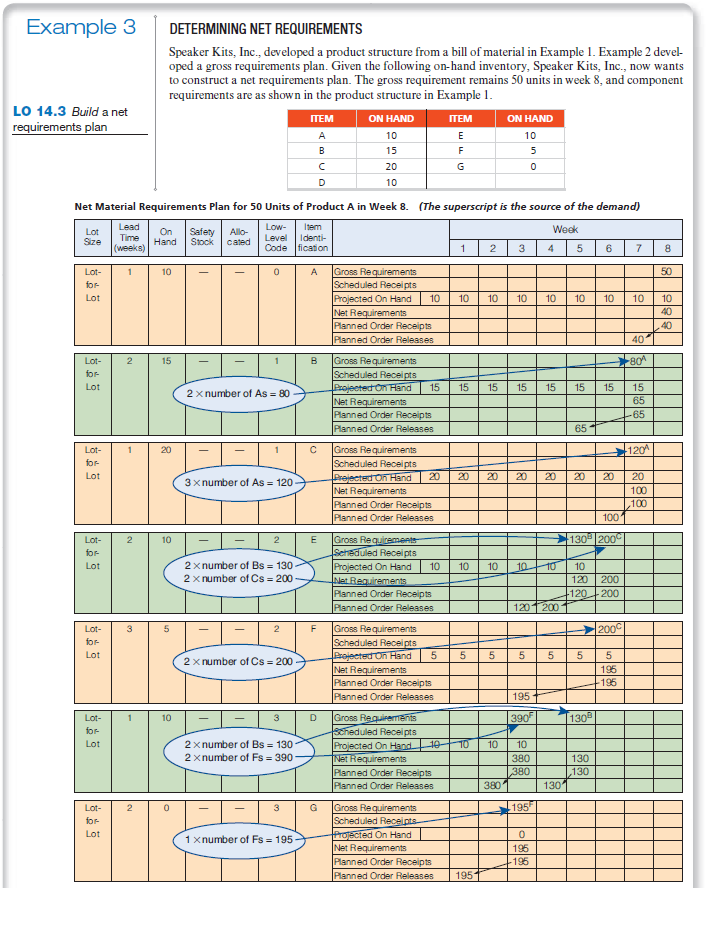

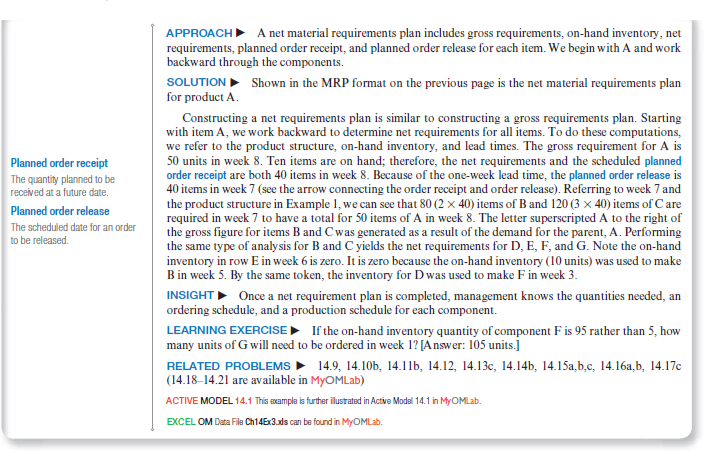

Example 3 DETERMINING NET REQUIREMENTS Speaker Kits, Inc., developed a product structure from a bill of material in Example 1. Example 2 devel- oped a gross requirements plan. Given the following on-hand inventory, Speaker Kits, Inc., now wants to construct a net requirements plan. The gross requirement remains 50 units in week 8, and component requirements are as shown in the product structure in Example 1. ITEM ON HAND ON HAND 10 B LO 14.3 Build a net requirements plan ITEM 10 15 20 E F 5 (mo O 10 Net Material Requirements Plan for 50 Units of Product A in Week 8. (The superscript is the source of the demand) On Low Item Week Safety Stock Identi- Level 5 7 Lot Size Lead Time (weeks) Allo- cated Hand Code fication 1 2 3 4 6 8 1 10 0 A 50 Lot- for Lot 10 10 10 10 10 10 10 Gross Requirements Scheduled Receipts Projected On Hand 10 Net Requirements Planned Order Receipts Planned Order Releases 10 40 40 407 2 15 1 B -80 Lot- for Lot 15 15 15 15 15 15 2 x number of As = 80 Gross Requirements Scheduled Receipts Projected On Hand 15 Net Requirements Planned Order Receipts Planned Order Releases |-65 65 1 20 1 1204 Lot- for Lot 20 20 20 20 20 3 x number of As = 120 Gross Requirements Scheduled Receipts Prejected On Hand 20 Net Requirements Planned Order Receipts Planned Order Releases 20 20 100 100 1001 2 10 2 E 130 2000 Lot- for Lot 10 10 2 x number of Bs = 130 2 x number of Cs = 200 10 10 Gross Requirements Scheduled Receipts Projected On Hand 10 Net Requirements Planned Order Receipts Planned Order Releases 10 120 | 200 -120 200 1201 200 3 5 2 F 2000 Lot- for Lot 5 5 al 5 on 2 x number of Cs = 200 Gross Requirements Scheduled Receipts Projected On Hand 5 Net Requirements Planned Order Receipts Planned Order Releases 5 196 196 195 Lot- 1 10 3 D 390F 130 for Lot TO 10 2 x number of Bs = 130 2 x number of Fs = 390 Gross Requirements Scheduled Receipts Projected On Hand 1e Net Requirements Planned Order Receipts Planned Order Releases 10 380 380 130 ,130 13011 380 2 0 3 195 Lot- for- Lot 1 x number of Fs = 195 Gross Requirements Scheduled Receipts- Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases 0 196 - 196 195 Planned order receipt The quantity planned to be received at a future date. Planned order release The scheduled date for an order to be released. APPROACH A net material requirements plan includes gross requirements, on-hand inventory, net requirements, planned order receipt, and planned order release for each item. We begin with A and work backward through the components. SOLUTION Shown in the MRP format on the previous page is the net material requirements plan for product A. Constructing a net requirements plan is similar to constructing a gross requirements plan. Starting with item A, we work backward to determine net requirements for all items. To do these computations, we refer to the product structure, on-hand inventory, and lead times. The gross requirement for A is 50 units in week 8. Ten items are on hand; therefore, the net requirements and the scheduled planned order receipt are both 40 items in week 8. Because of the one week lead time, the planned order release is 40 items in week 7 (see the arrow connecting the order receipt and order release). Referring to week 7 and the product structure in Example 1, we can see that 80 (2 x 40) items of Band 120 (3 x 40) items of Care required in week 7 to have a total for 50 items of A in week 8. The letter superscripted A to the right of the gross figure for items B and Cwas generated as a result of the demand for the parent, A. Performing the same type of analysis for B and yields the net requirements for D, E, F, and G. Note the on-hand inventory in row Ein week 6 is zero. It is zero because the on-hand inventory (10 units) was used to make Bin week 5. By the same token, the inventory for Dwas used to make F in week 3. INSIGHT Once a net requirement plan is completed, management knows the quantities needed, an ordering schedule, and a production schedule for each component. LEARNING EXERCISE If the on-hand inventory quantity of component Fis 95 rather than 5, how many units of G will need to be ordered in week 1? [Answer: 105 units.] RELATED PROBLEMS 14.9, 14.10b, 14.11b, 14.12, 14.13c, 14.145, 14.15a,b,c, 14.16a, b, 14.170 (14.18-14.21 are available in MyOMLab) ACTIVE MODEL 14.1 This example is further illustrated in Active Model 14.1 in My OMLab. EXCEL OM Data Fila Ch14x3.ds can be found in MyOMLab. Example 3 DETERMINING NET REQUIREMENTS Speaker Kits, Inc., developed a product structure from a bill of material in Example 1. Example 2 devel- oped a gross requirements plan. Given the following on-hand inventory, Speaker Kits, Inc., now wants to construct a net requirements plan. The gross requirement remains 50 units in week 8, and component requirements are as shown in the product structure in Example 1. ITEM ON HAND ON HAND 10 B LO 14.3 Build a net requirements plan ITEM 10 15 20 E F 5 (mo O 10 Net Material Requirements Plan for 50 Units of Product A in Week 8. (The superscript is the source of the demand) On Low Item Week Safety Stock Identi- Level 5 7 Lot Size Lead Time (weeks) Allo- cated Hand Code fication 1 2 3 4 6 8 1 10 0 A 50 Lot- for Lot 10 10 10 10 10 10 10 Gross Requirements Scheduled Receipts Projected On Hand 10 Net Requirements Planned Order Receipts Planned Order Releases 10 40 40 407 2 15 1 B -80 Lot- for Lot 15 15 15 15 15 15 2 x number of As = 80 Gross Requirements Scheduled Receipts Projected On Hand 15 Net Requirements Planned Order Receipts Planned Order Releases |-65 65 1 20 1 1204 Lot- for Lot 20 20 20 20 20 3 x number of As = 120 Gross Requirements Scheduled Receipts Prejected On Hand 20 Net Requirements Planned Order Receipts Planned Order Releases 20 20 100 100 1001 2 10 2 E 130 2000 Lot- for Lot 10 10 2 x number of Bs = 130 2 x number of Cs = 200 10 10 Gross Requirements Scheduled Receipts Projected On Hand 10 Net Requirements Planned Order Receipts Planned Order Releases 10 120 | 200 -120 200 1201 200 3 5 2 F 2000 Lot- for Lot 5 5 al 5 on 2 x number of Cs = 200 Gross Requirements Scheduled Receipts Projected On Hand 5 Net Requirements Planned Order Receipts Planned Order Releases 5 196 196 195 Lot- 1 10 3 D 390F 130 for Lot TO 10 2 x number of Bs = 130 2 x number of Fs = 390 Gross Requirements Scheduled Receipts Projected On Hand 1e Net Requirements Planned Order Receipts Planned Order Releases 10 380 380 130 ,130 13011 380 2 0 3 195 Lot- for- Lot 1 x number of Fs = 195 Gross Requirements Scheduled Receipts- Projected On Hand Net Requirements Planned Order Receipts Planned Order Releases 0 196 - 196 195 Planned order receipt The quantity planned to be received at a future date. Planned order release The scheduled date for an order to be released. APPROACH A net material requirements plan includes gross requirements, on-hand inventory, net requirements, planned order receipt, and planned order release for each item. We begin with A and work backward through the components. SOLUTION Shown in the MRP format on the previous page is the net material requirements plan for product A. Constructing a net requirements plan is similar to constructing a gross requirements plan. Starting with item A, we work backward to determine net requirements for all items. To do these computations, we refer to the product structure, on-hand inventory, and lead times. The gross requirement for A is 50 units in week 8. Ten items are on hand; therefore, the net requirements and the scheduled planned order receipt are both 40 items in week 8. Because of the one week lead time, the planned order release is 40 items in week 7 (see the arrow connecting the order receipt and order release). Referring to week 7 and the product structure in Example 1, we can see that 80 (2 x 40) items of Band 120 (3 x 40) items of Care required in week 7 to have a total for 50 items of A in week 8. The letter superscripted A to the right of the gross figure for items B and Cwas generated as a result of the demand for the parent, A. Performing the same type of analysis for B and yields the net requirements for D, E, F, and G. Note the on-hand inventory in row Ein week 6 is zero. It is zero because the on-hand inventory (10 units) was used to make Bin week 5. By the same token, the inventory for Dwas used to make F in week 3. INSIGHT Once a net requirement plan is completed, management knows the quantities needed, an ordering schedule, and a production schedule for each component. LEARNING EXERCISE If the on-hand inventory quantity of component Fis 95 rather than 5, how many units of G will need to be ordered in week 1? [Answer: 105 units.] RELATED PROBLEMS 14.9, 14.10b, 14.11b, 14.12, 14.13c, 14.145, 14.15a,b,c, 14.16a, b, 14.170 (14.18-14.21 are available in MyOMLab) ACTIVE MODEL 14.1 This example is further illustrated in Active Model 14.1 in My OMLab. EXCEL OM Data Fila Ch14x3.ds can be found in MyOMLab