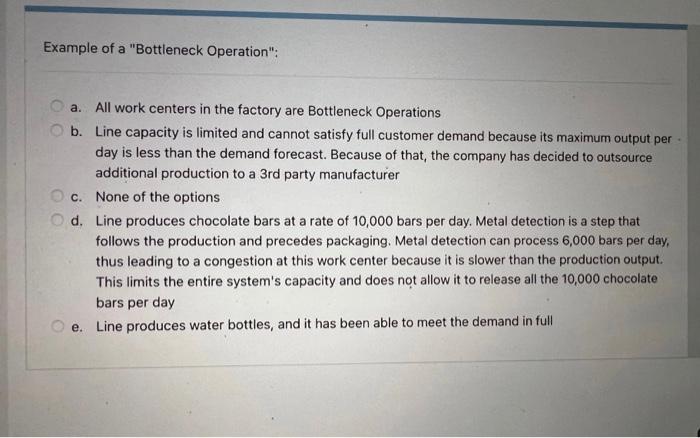

Question: Example of a Bottleneck Operation: a. All work centers in the factory are Bottleneck Operations b. Line capacity is limited and cannot satisfy full customer

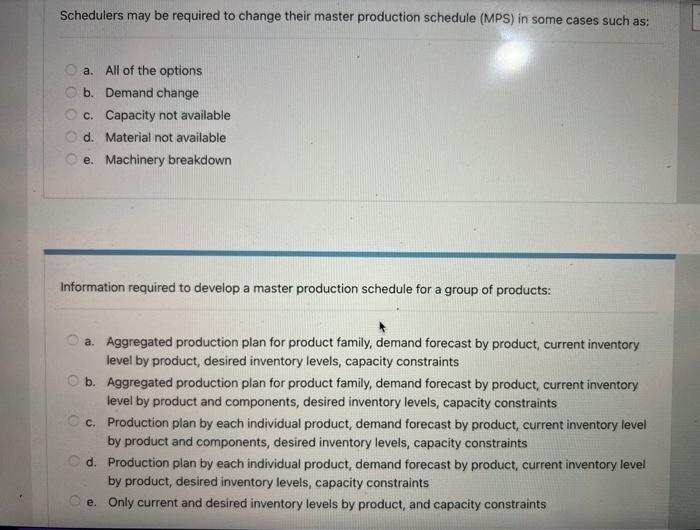

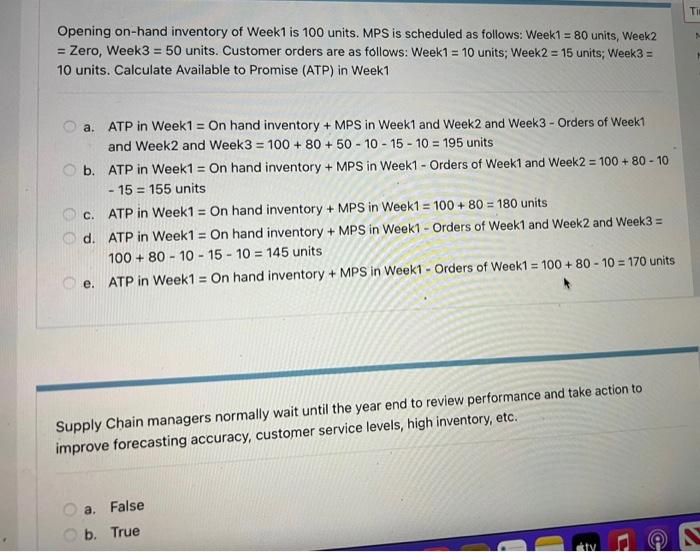

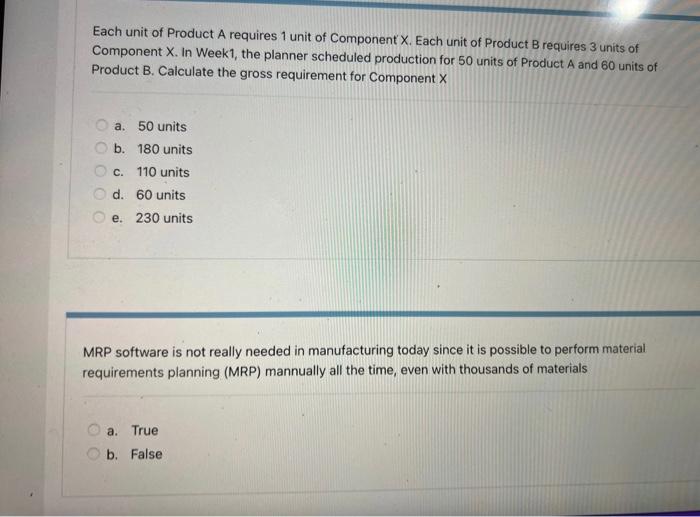

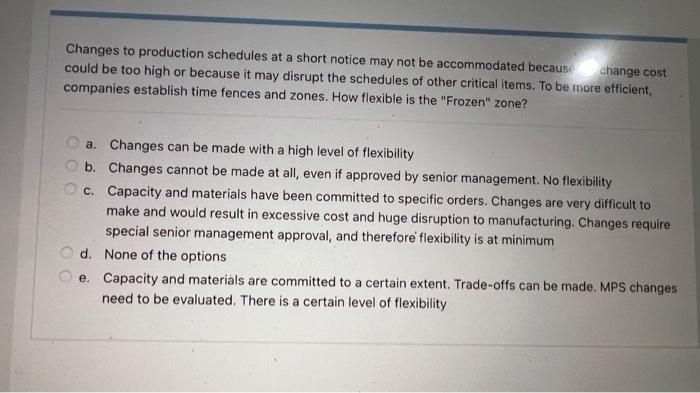

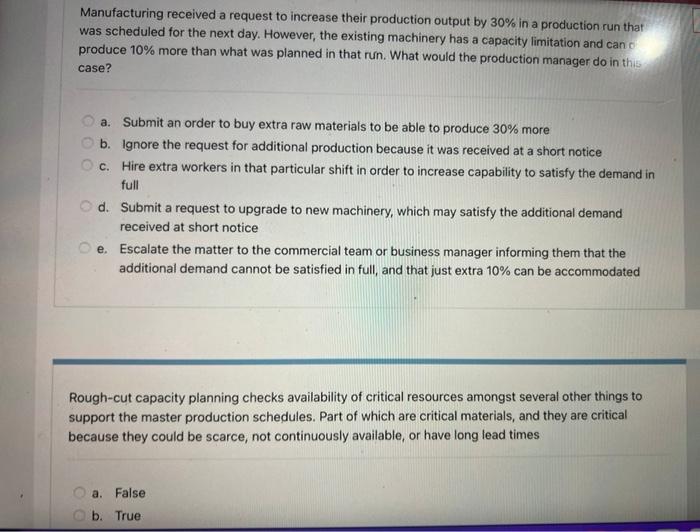

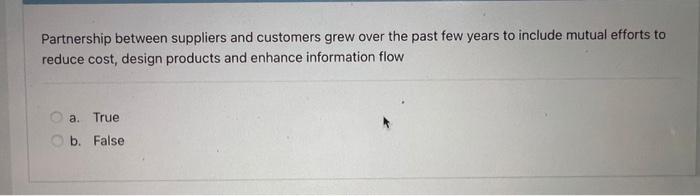

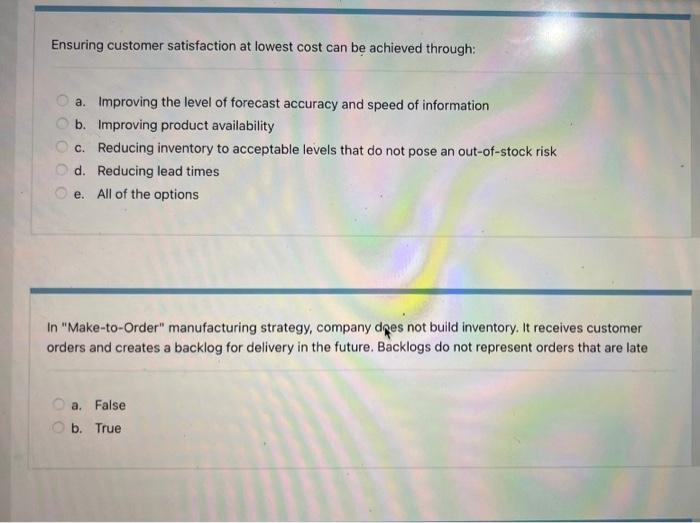

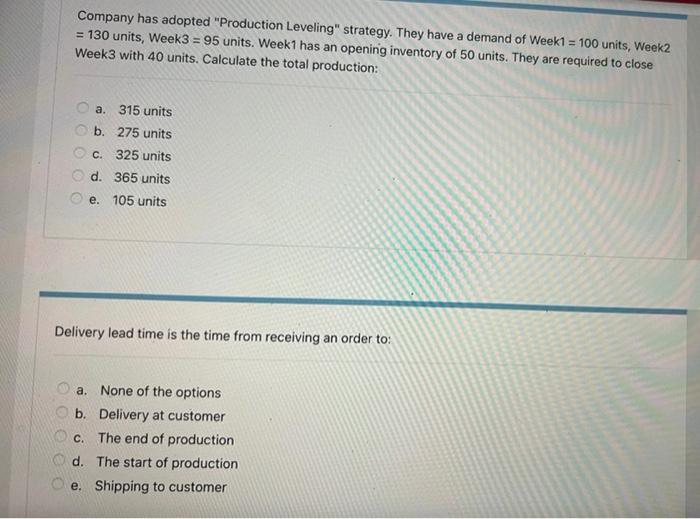

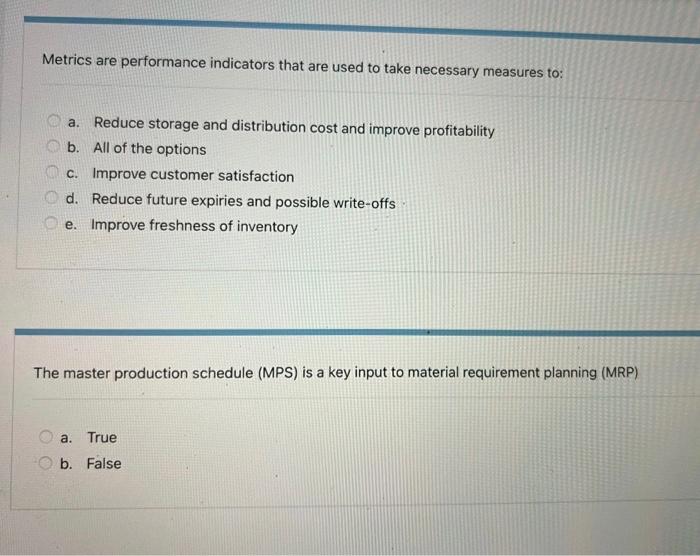

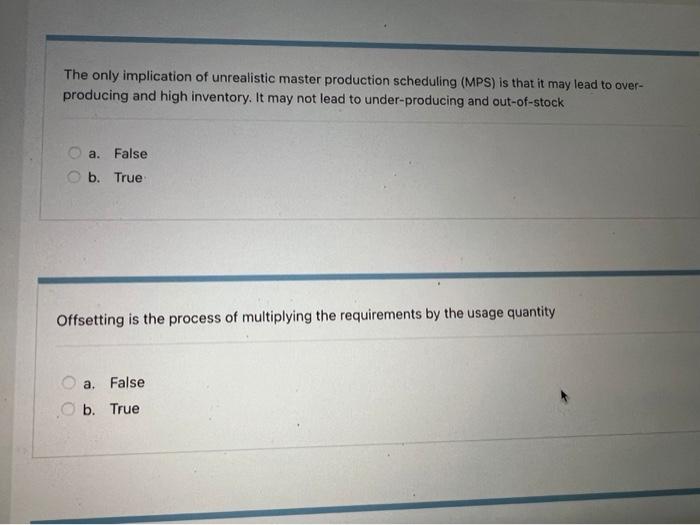

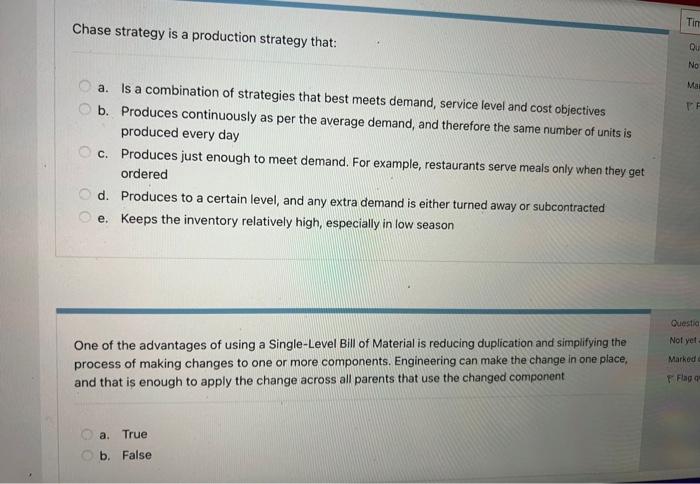

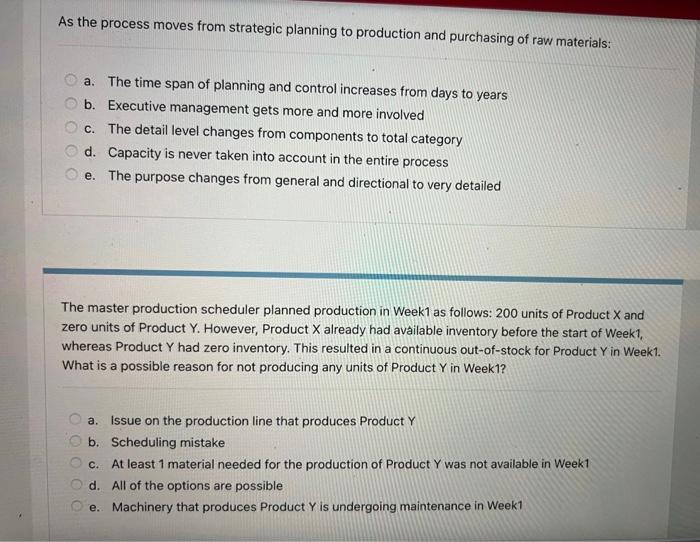

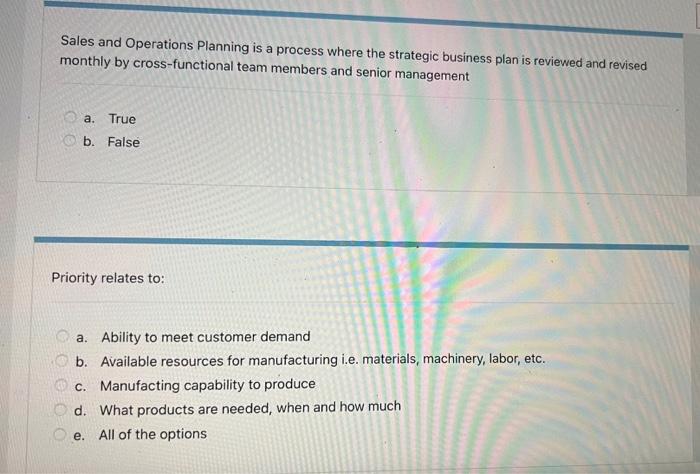

Example of a "Bottleneck Operation": a. All work centers in the factory are Bottleneck Operations b. Line capacity is limited and cannot satisfy full customer demand because its maximum output per day is less than the demand forecast. Because of that, the company has decided to outsource additional production to a 3rd party manufacturer c. None of the options d. Line produces chocolate bars at a rate of 10,000 bars per day. Metal detection is a step that follows the production and precedes packaging. Metal detection can process 6,000 bars per day, thus leading to a congestion at this work center because it is slower than the production output. This limits the entire system's capacity and does not allow it to release all the 10,000 chocolate bars per day e. Line produces water bottles, and it has been able to meet the demand in full Schedulers may be required to change their master production schedule (MPS) in some cases such as: a. All of the options b. Demand change C. Capacity not available d. Material not available e. Machinery breakdown Information required to develop a master production schedule for a group of products: a. Aggregated production plan for product family, demand forecast by product, current inventory level by product, desired inventory levels, capacity constraints b. Aggregated production plan for product family, demand forecast by product, current inventory level by product and components, desired inventory levels, capacity constraints c. Production plan by each individual product, demand forecast by product, current inventory level by product and components, desired inventory levels, capacity constraints d. Production plan by each individual product, demand forecast by product, current inventory level by product, desired inventory levels, capacity constraints e. Only current and desired inventory levels by product, and capacity constraints TE Opening on-hand inventory of Week1 is 100 units. MPS is scheduled as follows: Week1 = 80 units, Week2 = Zero, Week 3 = 50 units. Customer orders are as follows: Week1 = 10 units; Week2 = 15 units; Week3 = 10 units. Calculate Available to Promise (ATP) in Week1 a. ATP in Week1 = On hand inventory + MPS in Week1 and Week2 and Week 3 - Orders of Week1 and Week2 and Week 3 = 100 + 80 + 50 - 10 - 15 - 10 = 195 units b. ATP in Week1 = On hand inventory + MPS in Week1 - Orders of Week1 and Week2 = 100+80 - 10 - 15 = 155 units C. ATP in Week1 = On hand inventory + MPS in Week1 = 100 + 80 = 180 units d. ATP in Week1 = On hand inventory + MPS in Week1 - Orders of Week1 and Week2 and Week 3 = 100 + 80 - 10 - 15 - 10 = 145 units e ATP in Week1 = On hand inventory + MPS in Week1 - Orders of Week1 = 100 + 80 - 10 = 170 units = Supply Chain managers normally wait until the year end to review performance and take action to improve forecasting accuracy, customer service levels, high inventory, etc. a. False b. True @ Each unit of Product A requires 1 unit of Component X. Each unit of Product B requires 3 units of Component X. In Week 1, the planner scheduled production for 50 units of Product A and 60 units of Product B. Calculate the gross requirement for Component X a. 50 units b. 180 units c. 110 units d. 60 units e. 230 units MRP software is not really needed in manufacturing today since it is possible to perform material requirements planning (MRP) mannually all the time, even with thousands of materials a. True b. False Changes to production schedules at a short notice may not be accommodated because change cost could be too high or because it may disrupt the schedules of other critical items. To be more efficient, companies establish time fences and zones. How flexible is the "Frozen" zone? a. Changes can be made with a high level of flexibility b. Changes cannot be made at all, even if approved by senior management. No flexibility c. Capacity and materials have been committed to specific orders. Changes are very difficult to make and would result in excessive cost and huge disruption to manufacturing. Changes require special senior management approval, and therefore flexibility is at minimum d. None of the options e. Capacity and materials are committed to a certain extent. Trade-offs can be made. MPS changes need to be evaluated. There is a certain level of flexibility e Manufacturing received a request to increase their production output by 30% in a production run that was scheduled for the next day. However, the existing machinery has a capacity limitation and can produce 10% more than what was planned in that run. What would the production manager do in this case? a. Submit an order to buy extra raw materials to be able to produce 30% more b. Ignore the request for additional production because it was received at a short notice c. Hire extra workers in that particular shift in order to increase capability to satisfy the demand in full d. Submit a request to upgrade to new machinery, which may satisfy the additional demand received at short notice e. Escalate the matter to the commercial team or business manager informing them that the additional demand cannot be satisfied in full, and that just extra 10% can be accommodated Rough-cut capacity planning checks availability of critical resources amongst several other things to support the master production schedules. Part of which are critical materials, and they are critical because they could be scarce, not continuously available, or have long lead times a. False b. True Partnership between suppliers and customers grew over the past few years to include mutual efforts to reduce cost, design products and enhance information flow a. True b. False Ensuring customer satisfaction at lowest cost can be achieved through: a. Improving the level of forecast accuracy and speed of information b. Improving product availability c. Reducing inventory to acceptable levels that do not pose an out-of-stock risk d. Reducing lead times e. All of the options In "Make-to-Order" manufacturing strategy, company dpes not build inventory. It receives customer orders and creates a backlog for delivery in the future. Backlogs do not represent orders that are late a. False b. True Company has adopted "Production Leveling strategy. They have a demand of Week1 = 100 units, Week2 = 130 units, Week3 = 95 units. Week1 has an opening inventory of 50 units. They are required to close Week3 with 40 units. Calculate the total production: a. 315 units b. 275 units c. 325 units d. 365 units e. 105 units Delivery lead time is the time from receiving an order to: a. None of the options b. Delivery at customer C. The end of production d. The start of production e. Shipping to customer Metrics are performance indicators that are used to take necessary measures to: a. Reduce storage and distribution cost and improve profitability b. All of the options c. Improve customer satisfaction d. Reduce future expiries and possible write-offs e. Improve freshness of inventory The master production schedule (MPS) is a key input to material requirement planning (MRP) a. True b. False The only implication of unrealistic master production scheduling (MPS) is that it may lead to over- producing and high inventory. It may not lead to under-producing and out-of-stock a. False b. True Offsetting is the process of multiplying the requirements by the usage quantity a. False b. True Tin Chase strategy is a production strategy that: Qu No Mar PE a. Is a combination of strategies that best meets demand, service level and cost objectives b. Produces continuously as per the average demand, and therefore the same number of units is produced every day C. Produces just enough to meet demand. For example, restaurants serve meals only when they get ordered d. Produces to a certain level, and any extra demand is either turned away or subcontracted e. Keeps the inventory relatively high, especially in low season Questi Not yet Markod One of the advantages of using a Single-Level Bill of Material is reducing duplication and simplifying the process of making changes to one or more components. Engineering can make the change in one place, and that is enough to apply the change across all parents that use the changed component F Flag a. True b. False As the process moves from strategic planning to production and purchasing of raw materials: a. The time span of planning and control increases from days to years b. Executive management gets more and more involved C. The detail level changes from components to total category d. Capacity is never taken into account in the entire process e. The purpose changes from general and directional to very detailed The master production scheduler planned production in Week1 as follows: 200 units of Product X and zero units of Product Y. However, Product X already had available inventory before the start of Week1 whereas Product Y had zero inventory. This resulted in a continuous out-of-stock for Product Yin Week1. What is a possible reason for not producing any units of Product Y in Week 1? a. Issue on the production line that produces Product Y b. Scheduling mistake c. At least 1 material needed for the production of Product Y was not available in Week1 d. All of the options are possible e. Machinery that produces Product Y is undergoing maintenance in Week1 Sales and Operations Planning is a process where the strategic business plan is reviewed and revised monthly by cross-functional team members and senior management a. True b. False Priority relates to: e a. Ability to meet customer demand b. Available resources for manufacturing i.e. materials, machinery, labor, etc. C. Manufacting capability to produce d. What products are needed, when and how much e. All of the options