Question: Exercise 2 ( Process Involving Reaction and Separation ) Toluene is produced from n - heptane by dehydrogenation over a C r 2 O 3

Exercise Process Involving Reaction and Separation

Toluene is produced from heptane by dehydrogenation over a catalyst:

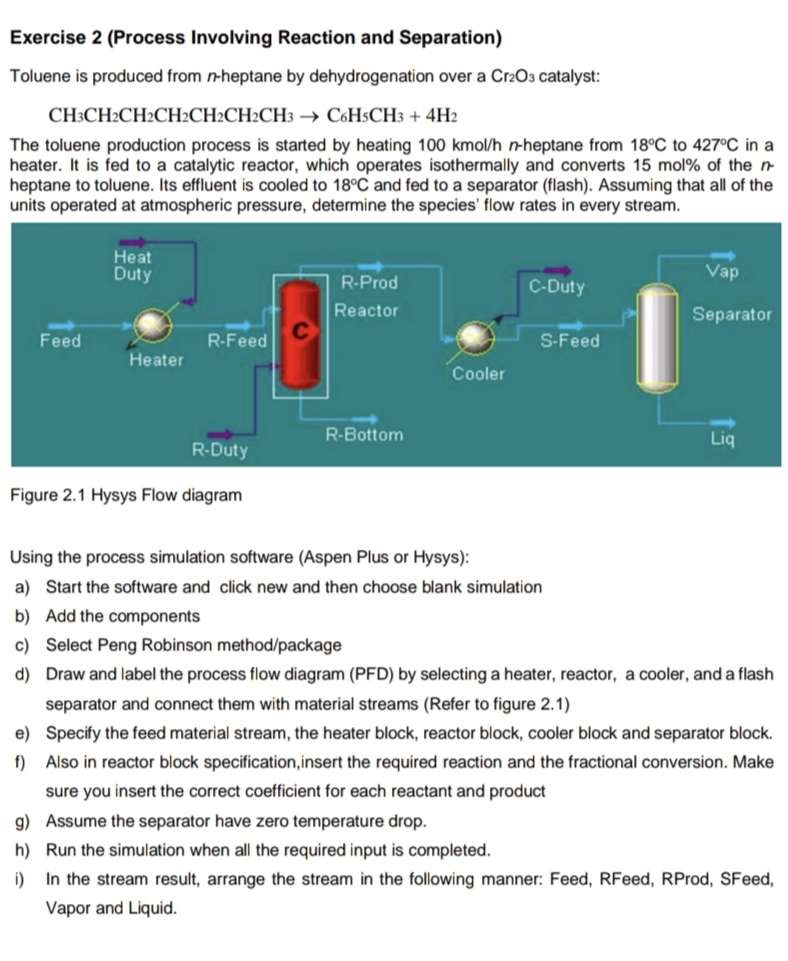

The toluene production process is started by heating kmoheptane from to in a heater. It is fed to a catalytic reactor, which operates isothermally and converts mol of the heptane to toluene. Its effluent is cooled to and fed to a separator flash Assuming that all of the units operated at atmospheric pressure, determine the species' flow rates in every stream.

Figure Hysys Flow diagram

Using the process simulation software Aspen Plus or Hysys:

a Start the software and click new and then choose blank simulation

b Add the components

c Select Peng Robinson methodpackage

d Draw and label the process flow diagram PFD by selecting a heater, reactor, a cooler, and a flash separator and connect them with material streams Refer to figure

e Specify the feed material stream, the heater block, reactor block, cooler block and separator block.

f Also in reactor block specification, insert the required reaction and the fractional conversion. Make sure you insert the correct coefficient for each reactant and product

g Assume the separator have zero temperature drop.

h Run the simulation when all the required input is completed.

i In the stream result, arrange the stream in the following manner: Feed, RFeed, RProd, SFeed, Vapor and Liquid.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock