Question: Exercise 4 It is required to decide how many cases of each of 4 types of parts to produce each week. There are already standing

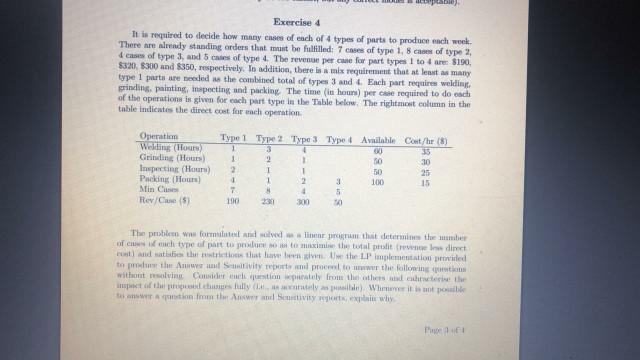

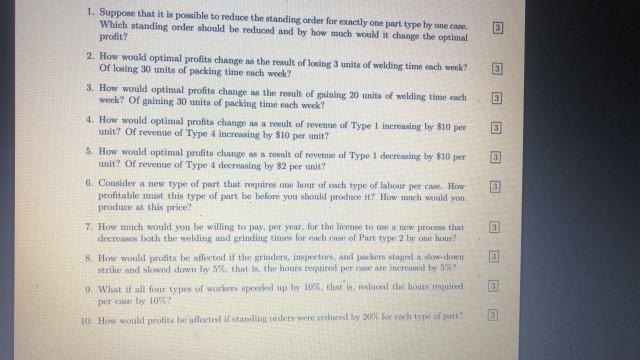

Exercise 4 It is required to decide how many cases of each of 4 types of parts to produce each week. There are already standing orders that must be fulfilled: 7 ches of type 1, 8 cases of type 2 4 case of type and 5 cans of type 4. The revenge per me for part types 1 to dar $190, $320, $300 and $350, respectively. In addition, there is a mix requirement that at least as many type 1 parts are needed as the combined total of types 3 and Each part require welding grindinis painting, inspecting and packing The time in hours) per case required to do each of the operations is given for each part type in the Table below. The right column in the table indicates the direct cost for each operation Operation Welding (Hours Grinding (Hous Inspection (Hons) Packing Hours) Alm (1) Rev/C (5) Type 1 Type 2 Type 3 Type & Available Cont/hr (8) 1 3 1 2 1 30 30 2 1 1 50 25 1 1 31 100 15 4 100 231 300 30 The problem we formate and dog that determine the one of me type of part to produto im the total procedirect and at the title that the LP implementation provided to the Anwes and Scivity report procl tower the following is without noin Consider wel opstely from the others where the it of the pas filly). When it is not pouble Destion from the Answer and Savior, explain why 3 3 3 3 1. Suppose that it is possible to reduce the standing order for exactly one part type by one Which standing order should be reduced and by how much would it change the optimal profit 2. How would optimal profits changes the real of losing 3 units of welding time each week? of losing 30 units of packing time each week? 3. How would optimal profits change the result of galning 20 units of welding time each week? Of gaining 30 units of packing time each week? 4. How would optimal profits change as a result of revenge of Type 1 increasing by $10 per unit? Of revenue of Type Increasing by $10 per unit? 5. How would optimal protits change as a result of revent of Type 1 decreasing by $10 per unit? Of revenue of Type I decreasing by 82 per unity 6. Consider a new type of part that requires one hour of each type of labour perc. How profitable mat this type of part be before you should produce it? How much would you produce at this price 17. How mich would you be willing to pay per year for the license to new process that der both the welding and grinding times for each one of Purt type 2 by one hour 8. How would profits be alerted if the grinders, inspections, and packers gedw.com strike and slowed down that is the housed per red by 9. What if all four types of workers pred up to that is real thouse e ty 1090 1. How would be betaling and we w 20% for coch 3 3 13 Exercise 4 It is required to decide how many cases of each of 4 types of parts to produce each week. There are already standing orders that must be fulfilled: 7 ches of type 1, 8 cases of type 2 4 case of type and 5 cans of type 4. The revenge per me for part types 1 to dar $190, $320, $300 and $350, respectively. In addition, there is a mix requirement that at least as many type 1 parts are needed as the combined total of types 3 and Each part require welding grindinis painting, inspecting and packing The time in hours) per case required to do each of the operations is given for each part type in the Table below. The right column in the table indicates the direct cost for each operation Operation Welding (Hours Grinding (Hous Inspection (Hons) Packing Hours) Alm (1) Rev/C (5) Type 1 Type 2 Type 3 Type & Available Cont/hr (8) 1 3 1 2 1 30 30 2 1 1 50 25 1 1 31 100 15 4 100 231 300 30 The problem we formate and dog that determine the one of me type of part to produto im the total procedirect and at the title that the LP implementation provided to the Anwes and Scivity report procl tower the following is without noin Consider wel opstely from the others where the it of the pas filly). When it is not pouble Destion from the Answer and Savior, explain why 3 3 3 3 1. Suppose that it is possible to reduce the standing order for exactly one part type by one Which standing order should be reduced and by how much would it change the optimal profit 2. How would optimal profits changes the real of losing 3 units of welding time each week? of losing 30 units of packing time each week? 3. How would optimal profits change the result of galning 20 units of welding time each week? Of gaining 30 units of packing time each week? 4. How would optimal profits change as a result of revenge of Type 1 increasing by $10 per unit? Of revenue of Type Increasing by $10 per unit? 5. How would optimal protits change as a result of revent of Type 1 decreasing by $10 per unit? Of revenue of Type I decreasing by 82 per unity 6. Consider a new type of part that requires one hour of each type of labour perc. How profitable mat this type of part be before you should produce it? How much would you produce at this price 17. How mich would you be willing to pay per year for the license to new process that der both the welding and grinding times for each one of Purt type 2 by one hour 8. How would profits be alerted if the grinders, inspections, and packers gedw.com strike and slowed down that is the housed per red by 9. What if all four types of workers pred up to that is real thouse e ty 1090 1. How would be betaling and we w 20% for coch 3 3 13

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock