Question: Facilities Planning and Design Problem - Machines 1 and 2 are operated by resources that work by a speed factor of 95% and the down

Facilities Planning and Design

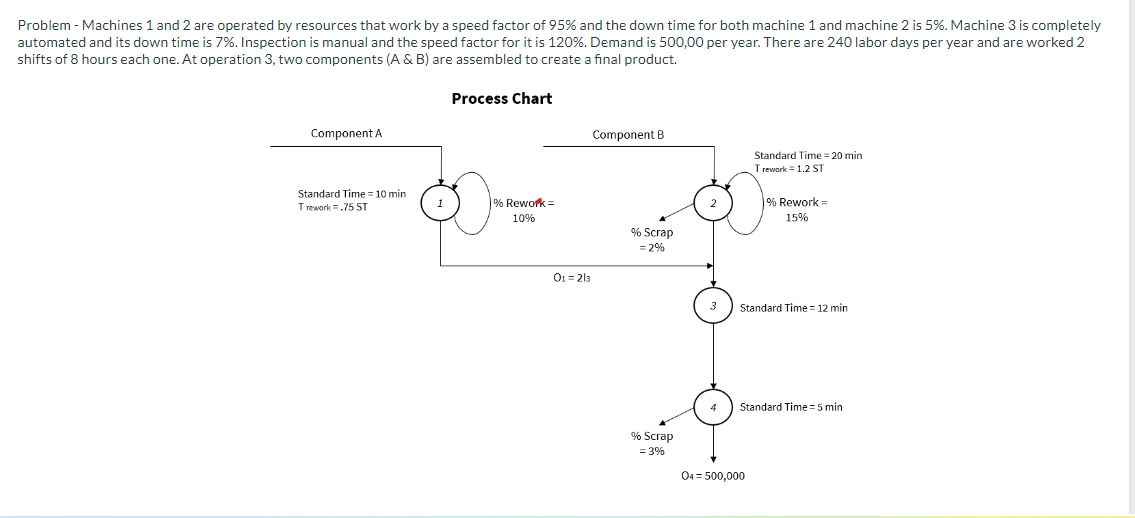

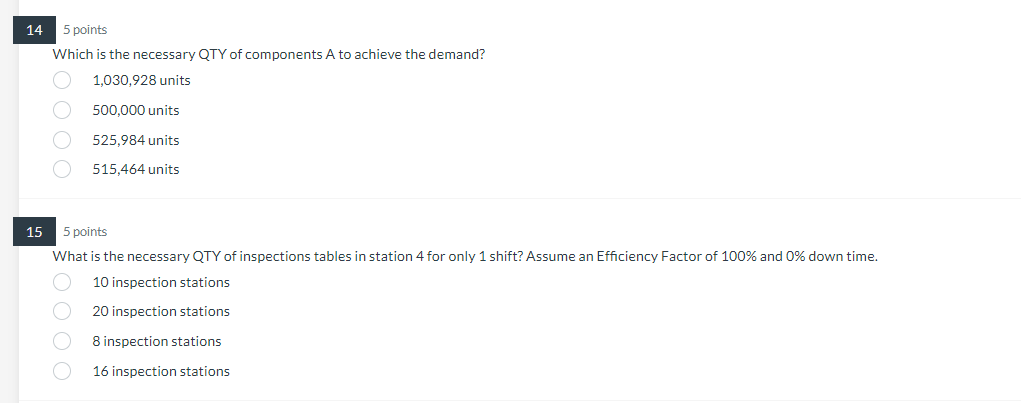

Problem - Machines 1 and 2 are operated by resources that work by a speed factor of 95% and the down time for both machine 1 and machine 2 is 5%. Machine 3 is completely automated and its down time is 7%. Inspection is manual and the speed factor for it is 120%. Demand is 500,00 per year. There are 240 labor days per year and are worked 2 shifts of 8 hours each one. At operation 3 , two components (A \& B) are assembled to create a final product. Which is the necessary QTY of components A to achieve the demand? 1,030,928 units 500,000 units 525,984 units 515,464 units 5 points What is the necessary QTY of inspections tables in station 4 for only 1 shift? Assume an Efficiency Factor of 100% and 0% down time. 10 inspection stations 20 inspection stations 8 inspection stations 16 inspection stations Problem - Machines 1 and 2 are operated by resources that work by a speed factor of 95% and the down time for both machine 1 and machine 2 is 5%. Machine 3 is completely automated and its down time is 7%. Inspection is manual and the speed factor for it is 120%. Demand is 500,00 per year. There are 240 labor days per year and are worked 2 shifts of 8 hours each one. At operation 3 , two components (A \& B) are assembled to create a final product. Which is the necessary QTY of components A to achieve the demand? 1,030,928 units 500,000 units 525,984 units 515,464 units 5 points What is the necessary QTY of inspections tables in station 4 for only 1 shift? Assume an Efficiency Factor of 100% and 0% down time. 10 inspection stations 20 inspection stations 8 inspection stations 16 inspection stations

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock