Question: facility planning industrial engineering 453 Select (True) or (False). If answer is false, mention the correct answer : 1. Facilities Planning is concerned with the

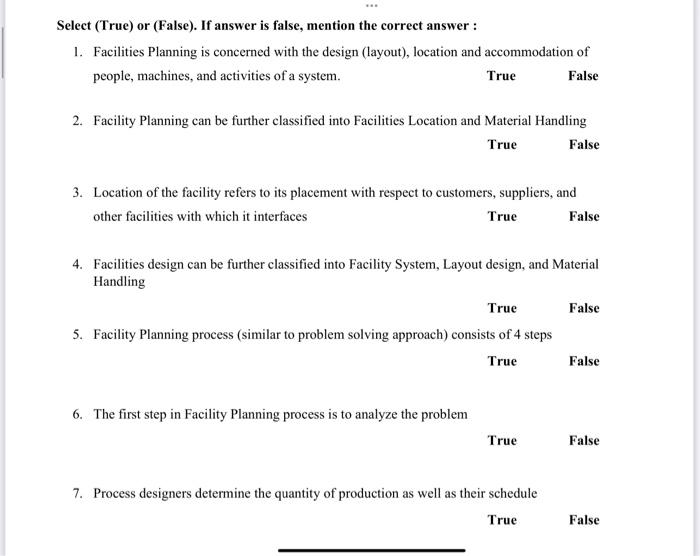

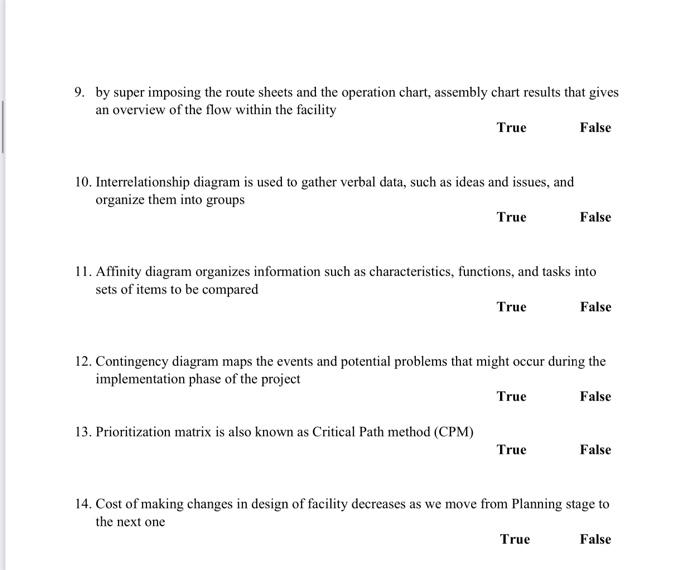

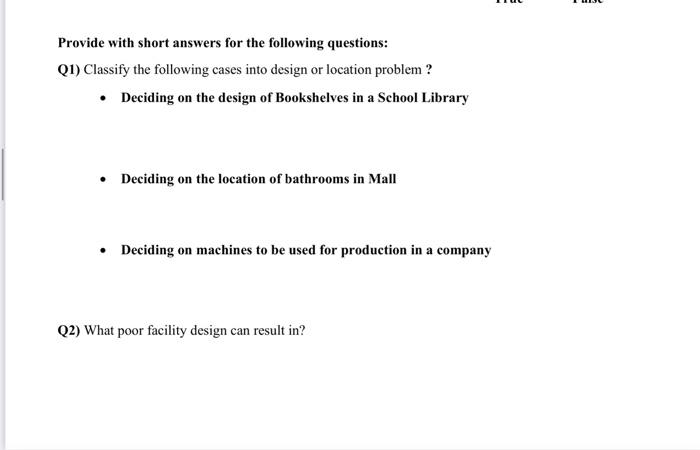

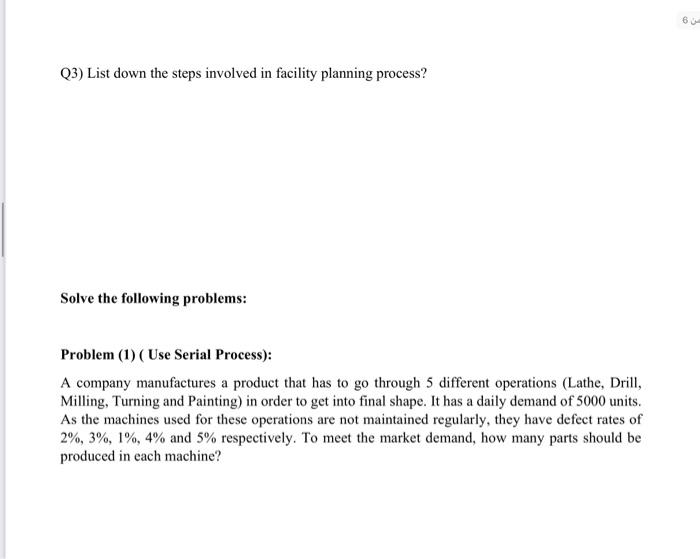

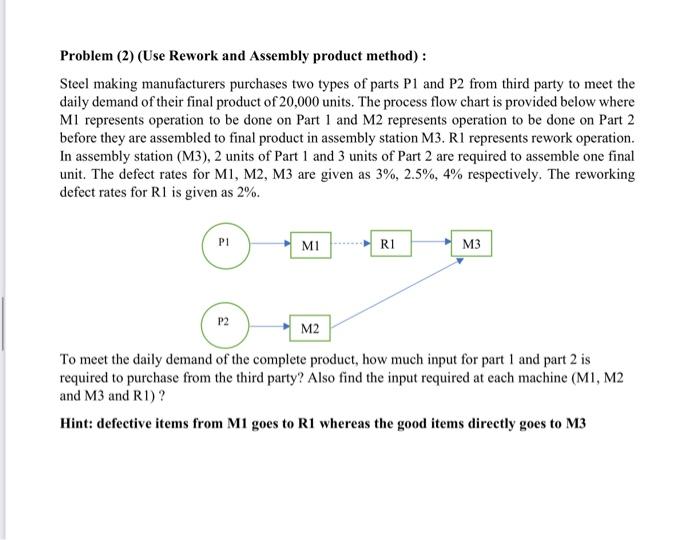

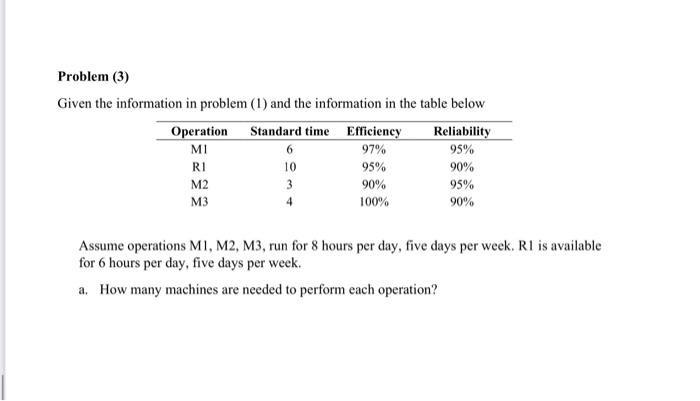

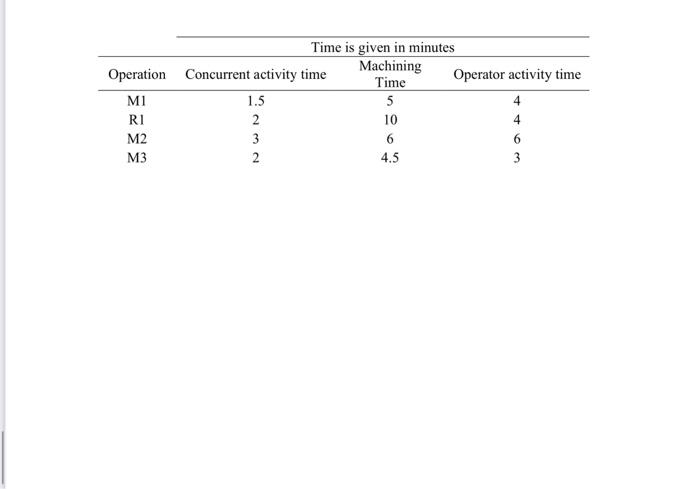

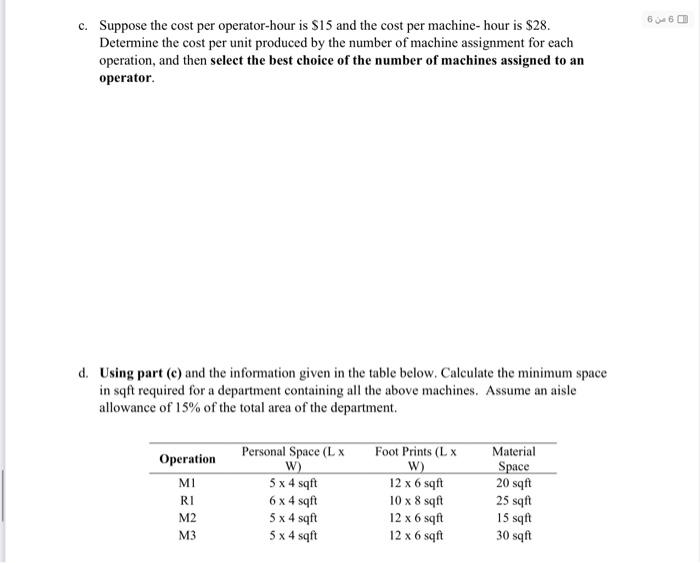

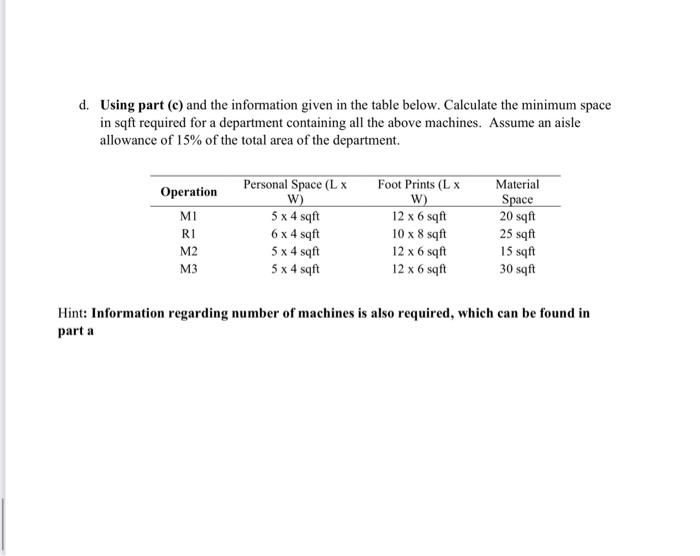

Select (True) or (False). If answer is false, mention the correct answer : 1. Facilities Planning is concerned with the design (layout), location and accommodation of people, machines, and activities of a system. TrueFalse 2. Facility Planning can be further classified into Facilities Location and Material Handling True False 3. Location of the facility refers to its placement with respect to customers, suppliers, and other facilities with which it interfaces True False 4. Facilities design can be further classified into Facility System, Layout design, and Material Handling True False 5. Facility Planning process (similar to problem solving approach) consists of 4 steps True False 6. The first step in Facility Planning process is to analyze the problem True False 7. Process designers determine the quantity of production as well as their schedule 9. by super imposing the route sheets and the operation chart, assembly chart results that gives an overview of the flow within the facility TrueFalse 10. Interrelationship diagram is used to gather verbal data, such as ideas and issues, and organize them into groups TrueFalse 11. Affinity diagram organizes information such as characteristics, functions, and tasks into sets of items to be compared True False 12. Contingency diagram maps the events and potential problems that might occur during the implementation phase of the project TrueFalse 13. Prioritization matrix is also known as Critical Path method (CPM) True False 14. Cost of making changes in design of facility decreases as we move from Planning stage to the next one True False Provide with short answers for the following questions: Q1) Classify the following cases into design or location problem ? - Deciding on the design of Bookshelves in a School Library - Deciding on the location of bathrooms in Mall - Deciding on machines to be used for production in a company Q2) What poor facility design can result in? Q3) List down the steps involved in facility planning process? Solve the following problems: Problem (1) ( Use Serial Process): A company manufactures a product that has to go through 5 different operations (Lathe, Drill, Milling, Turning and Painting) in order to get into final shape. It has a daily demand of 5000 units. As the machines used for these operations are not maintained regularly, they have defect rates of 2%,3%,1%,4% and 5% respectively. To meet the market demand, how many parts should be produced in each machine? Problem (2) (Use Rework and Assembly product method) : Steel making manufacturers purchases two types of parts P1 and P2 from third party to meet the daily demand of their final product of 20,000 units. The process flow chart is provided below where M1 represents operation to be done on Part 1 and M2 represents operation to be done on Part 2 before they are assembled to final product in assembly station M3. R1 represents rework operation. In assembly station (M3), 2 units of Part 1 and 3 units of Part 2 are required to assemble one final unit. The defect rates for M1,M2,M3 are given as 3%,2.5%,4% respectively. The reworking defect rates for R1 is given as 2%. To meet the daily demand of the complete product, how much input for part 1 and part 2 is required to purchase from the third party? Also find the input required at each machine (M1, M2 and M3 and R1) ? Hint: defective items from M1 goes to R1 whereas the good items directly goes to M3 Given the information in problem (1) and the information in the table below Assume operations M1, M2, M3, run for 8 hours per day, five days per week. R1 is available for 6 hours per day, five days per week. a. How many machines are needed to perform each operation? Time is given in minutes \begin{tabular}{cccc} \hline Operation & Concurrent activity time & MachiningTime & Operator activity time \\ \hline M1 & 1.5 & 5 & 4 \\ R1 & 2 & 10 & 4 \\ M2 & 3 & 6 & 6 \\ M3 & 2 & 4.5 & 3 \end{tabular} c. Suppose the cost per operator-hour is $15 and the cost per machine-hour is $28. Determine the cost per unit produced by the number of machine assignment for each operation, and then select the best choice of the number of machines assigned to an operator. d. Using part (c) and the information given in the table below. Calculate the minimum space in sqft required for a department containing all the above machines. Assume an aisle allowance of 15% of the total area of the department. d. Using part (c) and the information given in the table below. Calculate the minimum space in sqft required for a department containing all the above machines. Assume an aisle allowance of 15% of the total area of the department. Hint: Information regarding number of machines is also required, which can be found in part a

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts