Question: ffinancial reporting. These cross-unit processes The company understood, however, that were the ones most distorted by the frag- just having the data doesn't necessarily mean

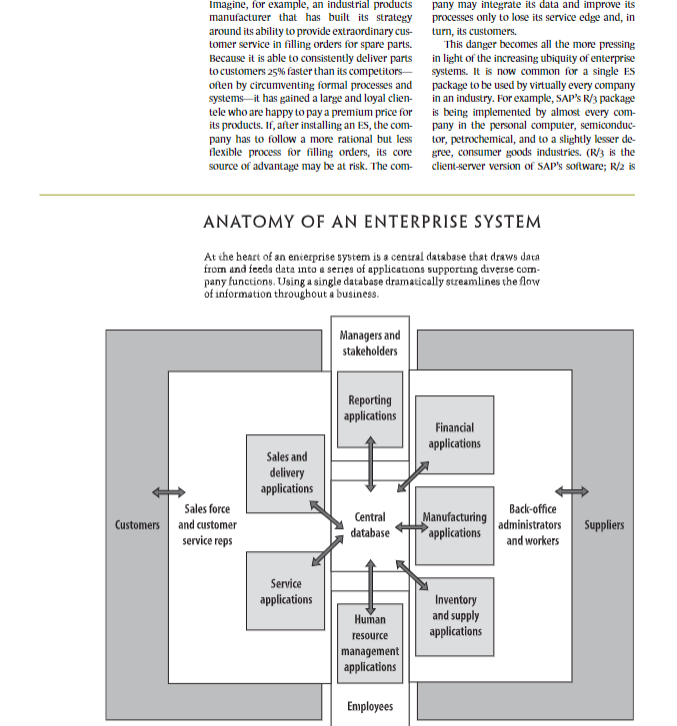

\ffinancial reporting. These cross-unit processes The company understood, however, that were the ones most distorted by the frag- just having the data doesn't necessarily mean mented organizational structure. Moreover, the data will be used well. Computer systems they had the greatest impact on the company's alone don't change organizational behavior. It ability to manage its customer relationships in therefore established a new position-demand a way that would both enhance customer satis- manager-to be the focal point for the inte- faction and improve corporate profitability. grated sales and production-planning process. Each of the processes was redesigned to take Drawing on the enterprise system, the demand full advantage of the new system's capabilities, manager creates the initial sales forecast, up- in particular its ability to simplify the flow of dates it with each new order, assesses plant ca- information. Layers of information middle- pacity and account profitability, and develops men-once necessary for transferring informa- detailed production plans. The demand man- tion across incompatible unit and corporate ager is able to schedule a customer's order- systems were eliminated in order to speed and promise a delivery date-up to six weeks the flow of work and reduce the likelihood of ahead of production. Previously, production errors. could be allocated to individual orders no To maintain its focus on the customer, the more than a week in advance. Now central to company chose to install only those R/3 mod- the company's operation, the role of demand ules required to support the four targeted pro- manager could not even have existed in the cesses. It did not, for example, install the mod- past because the information needed to per- ules for human resource management or plant form it was scattered all over the company. maintenance. Those functions did not have a The way Elf Atochem is managing the imple- direct impact on customers, and the existing mentation effort also reflects the breadth of its Only a general manager information systems that supported them goals. The project is being led by a 60-person were considered adequate. core implementation team, which reports to a is equipped to act as a Elf Atochem also made fundamental member of the company's executive commit- mediator between the changes to its organizational structure. In the tee. The team includes both business analysts financial area, for example, all the company's and information technologists, and is assisted imperatives of the accounts-receivable and credit departments by a set of so-called super users, representing technology and of the were combined into a single corporate func the business units and corporate functions. tion. This change enabled the company to con- These super users help ensure that decisions business. solidate all of a customer's orders into a single about the system's configuration are made with account and issue a single invoice. It also al- the broadest possible understanding of the busi- lowed the company to monitor and manage ness. They also play a crucial role in explaining overall customer profitability-something that the new system to their respective departments had been impossible to do when orders were and training people in its use. fragmented across units. In addition, Elf The team is installing the ES one business Atochem combined all of its units' customer- unit at a time, with each unit implementing service departments into one department, pro- the same system configuration and set of pro- riding each customer with a single point of cedures for order processing, supplier manage- contact for checking on orders and resolving ment, and financial reporting. The unit-by-unit problems. process ensures that the effort is manageable, Perhaps most important, the system gave and it also helps the team refine the system Elf Atochem the real-time information it and the processes as it proceeds. For example, needed to connect sales and production plan- the second unit to implement the system ning-demand and supply-for the first time. found that it didn't adequately support bulk As orders are entered or changed, the system shipments, which are the main way the unit automatically updates forecasts and factory gets its products to customers. (The first unit schedules, which enables the company to uses package shipping for all its orders.) The quickly alter its production runs in response to system was then modified to support bulk as customers needs. Only one other company in well as package shipping, and the new configu- the industry had this capability, which meant ration became the new standard. that Elf Atochem gained an important edge Using the large and broadly representative plement with the\f\f\forders needed parts from suppliers; and sched- Now, having installed an ES, it ships 98% of its ules assembly in the company's factory in Tai- orders within 24 hours. IBM's Storage Systems wan. division reduced the time required to reprice The sales and production forecasts are im- all of its products from 5 days to 5 minutes, the mediately updated, and a material-require- time to ship a replacement part from 22 days ments-planning list and bill of materials are to 3 days, and the time to complete a credit created. The sales rep's payroll account is cred- check from 20 minutes to 3 seconds. Fujitsu ited with the correct commission, in French Microelectronics reduced the cycle time for francs, and his travel account is credited with filling orders from 18 days to a day and a half the expense of the sales call. The actual prod- and cut the time required to close its financial uct cost and profitability are calculated, in books from & days to 4 days. U.5. dollars, and the divisional and corporate balance sheets, the accounts-payable and when System and Strategy Clash accounts receivable ledgers, the cost-center Clearly, enterprise systems offer the potential accounts, and the corporate cash levels are all of big benefits. But the very quality of the sys- automatically updated. The system performs tems that makes those benefits possible- nearly every information transaction resulting their almost universal applicability-also pre- from the sale. sents a danger. When developing information An ES streamlines a company's data flows systems in the past, companies would first de- and provides management with direct access cide how they wanted to do business and then to a wealth of real-time operating information. choose a software package that would support For many companies, these benefits have their proprietary processes. They often re- translated into dramatic gains in productivity wrote large portions of the software code to and speed. ensure a tight fit. With enterprise systems, Autodesk, a leading maker of computer- however, the sequence is reversed. The busi- aided design software, used to take an average ness often must be modified to fit the system. of two weeks to deliver an order to a customer. An enterprise system is, after all, a generic solution. Its design reflects a series of assump- tions about the way companies operate in gen- eral. Vendors try to structure the systems to re- The Scope of an Enterprise System flect best practices, but it is the vendor, not the customer, that is defining what "best" means. An enterprise system enables a company to integrate the data used throughout its In many cases, the system will enable a com- entire organization. This list shows some of the many functions supported by SAP's pany to operate more efficiently than it did be- R/3 package. fore. In some cases, though, the system's as- Financials Operations and Logistics sumptions will run counter to a company's Accounts receivable and payable Inventory management best interests. Asset accounting Material requirements planning Some degree of ES customization is possi- Materials management ble. Because the systems are modular, for in- Cash management and forecasting Cost-element and cost-center accounting Plant maintenance stance, companies can install only those mod- Executive information system Production planning ules that are most appropriate to their Financial consolidation Project management business. However, the system's complexity General ledger Purchasing makes major modifications impracticably. (See Product-cost accounting Quality management the sidebar "Configuring an Enterprise Sys- Profitability analysis Routing management tem.") As a result, most companies installing Profit-center accounting Shipping enterprise systems will need to adapt or even completely rework their processes to fit the re- Standard and period-related costing Vendor evaluation quirements of the system. An executive of one Human Resources Sales and Marketing company that has adopted SAP's system sums Human-resources time accounting Order management it up by saying, "SAP isn't a software package; Payroll Pricing it's a way of doing business." The question is, Is Personnel planning Sales management it the best way of doing business? Do the sys- Travel expenses Sales planning tem's technical imperatives coincide or con- flict with the company's business imperatives?\f\f\f\fstance identification codes. While customer terprise system would be the best way to inte- and factory data have not been fully standard- grate the data flows, and they decided to go ized-differences among the units' customers with SAP's R/3 system, which was rapidly be- and manufacturing processes are too great to coming the standard in the industry. But they accommodate common data-Monsanto has never labeled the ES project as simply a tech- achieved a remarkable degree of commonality nology initiative. Rather, they viewed it as an across a diverse set of global businesses. opportunity to take a fresh look at the com- At Hewlett-packard, a company with a pany's strategy and organization. strong tradition of business-unit autonomy, Looking beyond the technology, the execu- management has not pushed for commonality tives saw that the real source of Elf Atochem's across the several large divisions that are im- difficulties was not the fragmentation of its plementing SAP's enterprise system. Except systems but the fragmentation of its organiza- for a small amount of common financial data tion. Although the 12 business units shared necessary to roll up results for corporate re- many of the same customers, each unit was porting, HP's federalist approach gives all the managed autonomously. From the customer's power to the "states" where ES decisions are perspective, the lack of continuity among units concerned. This approach fits the HP culture made doing business with the company a trial. well, but it's very expensive. Each divisional ES To place a single order, a customer would fre- has had to be implemented separately, with lit- quently have to make many different phone ile sharing of resources. Managers estimate calls to many different units. And to pay for that well over a billion dollars will be spent the order, the customer would have to process across the corporation before the various a series of invoices. projects are completed. Inside the company, things were equally con- Those companies that fused. It took four days-and seven handoffs be- Doing It Right at Elf Atochem tween departments-to process an order, even stressed the enterprise, Considering an ES's far reaching strategic and though only four hours of actual work were in- not the system, gained organizational implications, the worst thing a volved. Because each unit managed inventory company can do is to make decisions about a and scheduled production independently, the the greatest benefits. system based on technical criteria alone. In company was unable to consolidate inventory fact, having now studied more than so busi- or coordinate manufacturing at the corporate nesses with enterprise systems, I can say with level. More than $6 million in inventory was some confidence that the companies deriving written off every year, and plants had to be shut the greatest benefits from their systems are down frequently for unplanned production-line those that, from the start, viewed them prima- changes. And because ordering and production rily in strategic and organizational terms. systems were not linked, sales representatives They stressed the enterprise, not the system. couldn't promise firm delivery dates, which Elf Atochem North America, a $2 billion re- translated into lost customers. gional chemicals subsidiary of the French com- Management knew that in the petrochemi pany Elf Aquitaine, is a good case in point. Fol- cals business, where many products are com- lowing a series of mergers in the early 19905, modities, the company that can offer the best Elf Atochem found itself hampered by the customer service often wins the order. So it fragmentation of critical information systems structured the implementation of its ES in a among its 12 business units. Ordering systems way that would enable it to radically improve were not integrated with production systems. its service levels. Its goal was to transform itself Sales forecasts were not tied to budgeting sys- from an industry laggard into an industry tems or to performance-measurement systems. leader. Even though many competitors were Each unit was tracking and reporting its finan- also adopting the R/3 package, Elf Atochem cial data independently. As a result of the knew that if it could achieve a tighter, many incompatible systems, operating data smoother fit between its business processes were not flowing smoothly through the organi- and the system, it could gain and maintain a zation, and top management was not getting service advantage. the information it needed to make sound and The company decided to focus its efforts on timely business decisions. four key processes: materials management, The company's executives saw that an en- production planning, order management, andReect 8: Share . What are some of the critical success factors for ERP implementations? . Dd you think the article is still relevant today? Why.I cirwhv not? - What is the current state of enterprise systems today? That is. what are some changes that we see today in the world of technology and their impact [if any] on enterprise systems

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts