Question: Find the same solution please Figure 1 0 . 3 1 shows a 1 2 in . - 1 3 UNC grade 5 steel bolt

Find the same solution please

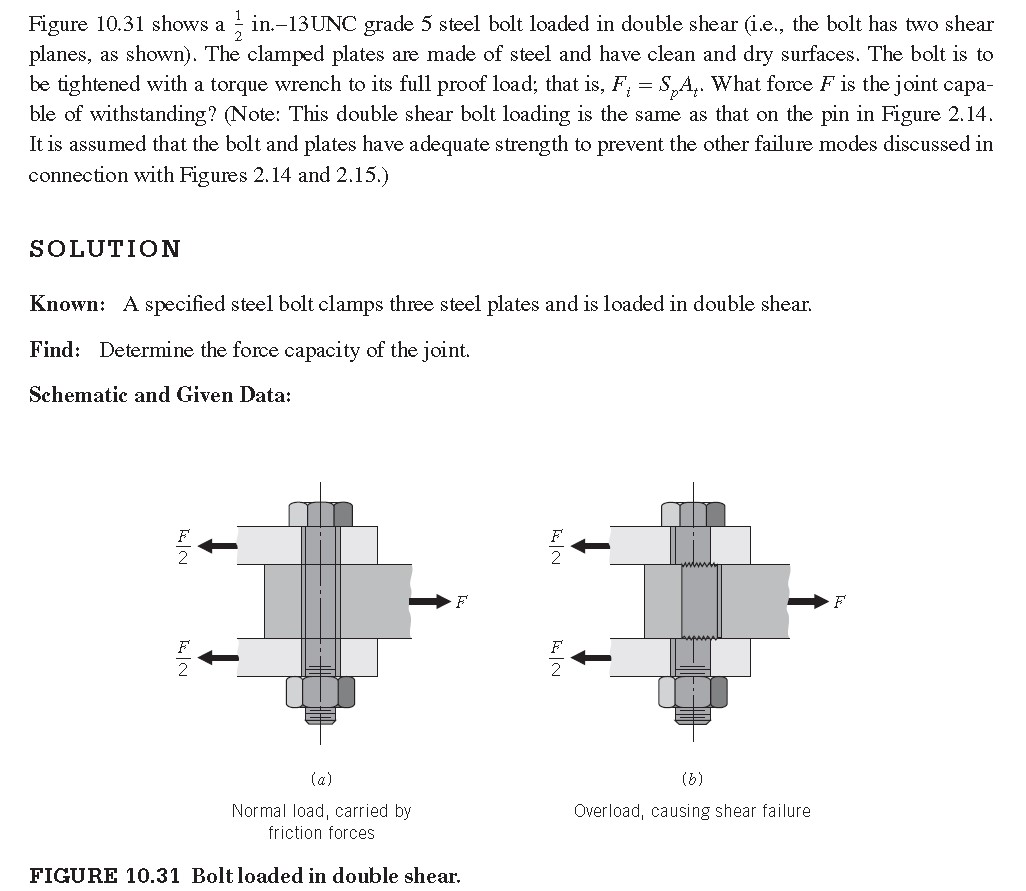

Figure shows a in UNC grade steel bolt loaded in double shear ie the bolt has two shear

planes, as shown The clamped plates are made of steel and have clean and dry surfaces. The bolt is to

be tightened with a torque wrench to its full proof load; that is What force is the joint capa

ble of withstanding? Note: This double shear bolt loading is the same as that on the pin in Figure

It is assumed that the bolt and plates have adequate strength to prevent the other failure modes discussed in

connection with Figures and

SOLUTION

Known: A specified steel bolt clamps three steel plates and is loaded in double shear.

Find: Determine the force capacity of the joint.

Schematic and Given Data: Assumptions:

The bolt is tightened to its full proof load; that is

The bolt fails in double shear.

The bolt and plates have adequate strength to prevent other failure modes.

The wrenchtorque variation is roughly

There is a initial loss in tension during the first few weeks of service see Section

Analysis:

For the inUNC grade steel bolt, Table gives and Table shows

that ksi. Specified initial tension is But

with a roughly estimated torquewrench variation and initialtension loss during the

first few weeks of service see Section a conservative assumption of working value of is

about lb

Reference gives a summary p of friction coefficients obtained with bolted plates. The coefficient

for semipolished steel is approximately and for sand or gritblasted steel approximately Various

paints, platings, and other surface treatments can alter the coefficient markedly, usually downward. Here

a friction coefficient of is assumed. This gives a force required to slip each of the two interfaces of

Thus, the value of required to overcome friction is estimated to be in the

region of lb

Although it is often desirable to limit applied load to the value that can be transmitted by friction, we

should know the larger value of force that can be transmitted through the bolt itself. For the two shear

planes involved, this force is equal to where is the area of the bolt at the shear planesin

this case, in Taking advantage of the fact that the distortion energy theory gives a

good estimate of shear yield strength for ductile metals, we have ksiksi.

Thus, for yielding of the two shear planes,

The estimated load would bring the shear stress to the yield strength over the entire cross

section of the shear planes, and the very small amount of yielding would probably result in losing most

or all of the clamping and friction forces. A further increase in load would cause total shear failure, as

indicated in Figure This total failure load is calculated as in step except for replacing with

From Eq~~ksi, the corresponding estimated load is

Comment: Note that in Figure the threaded portion of the bolt does not extend to the shear plane. This

is important for a bolt loaded in shear. Extending the thread to the shear plane is conservatively considered to

reduce the she ar area to a circle equal to the thread root diameter; in this case,

which is a reduction of

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock