Question: First option: Increase the batch size. This option seemed pretty good because it didnt require an immediate purchase of any new equipment or hiring of

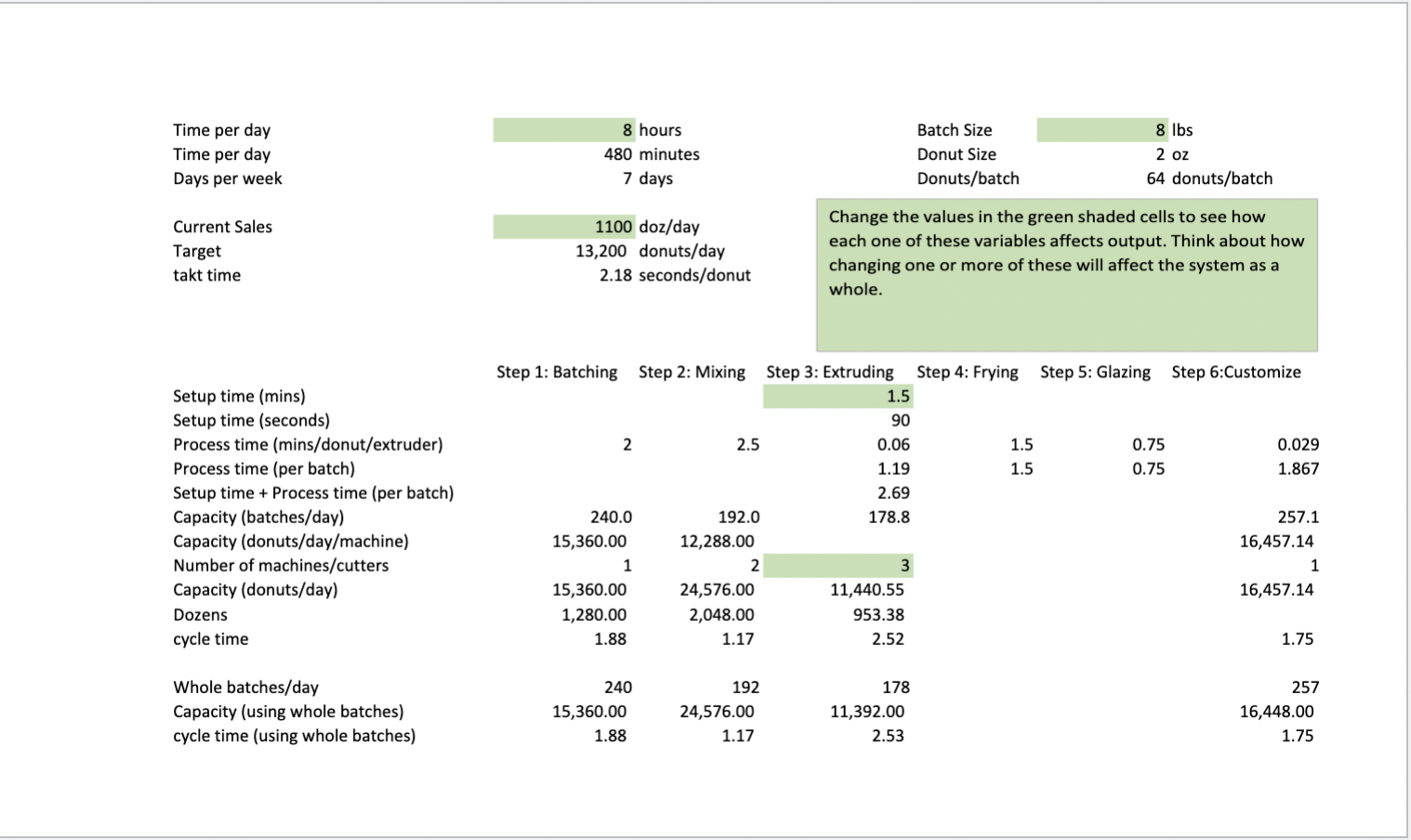

First option: Increase the batch size. This option seemed pretty good because it didnt require an immediate purchase of any new equipment or hiring of any new employees. At face value, it seemed like the lowest-cost solution. That is until you start to consider the additional wear and tear on the mixing equipment that larger batch sizes would cause. Dewey had no way of knowing exactly how quickly the machinery would wear out if he increased the batch sizes, but he knew this was a drawback. Even though hed like to avoid this option and extend the life of his mixers, Dewey wants to know exactly how large his batch size needs to be in order to meet the daily demand without changing either the number of cutting heads on the extruder or the setup time on the extruder. Working with whole batches only (no partial batches allowed), what batch size in pounds, rounded to the nearest tenth of a pound, is needed to meet his customer demand with out changing the number of cutting heads on the extruder or the setup time of the extruder?

Second option: Add cutters to the extruder. Johnson also considered adding an additional three cutters to the extruder. He knew this would increase the rate at which donuts could be cut and shaped, but he also knew that it would add to the cleaning and setup which had to be performed prior to each step and that it would cost him to purchase and install the new cuttersmaking this, again, not the ideal option but a feasible one. In order to make an informed decision, he needs to know this: Working with whole batches only (no partial batches allowed), what is the maximum setup time in minutes, rounded to the nearest tenth of a minute, that could be allowed for each batch if he were to add an additional three cutters without changing the current batch size of eight pounds?

Third option: Reduce the setup time. Finally, Dewey Johnson has realized that if he could reduce the time it takes to clean and prep the extruder before each batch, he can cut out enough non-value-added time to produce what is needed without any additional wear and tear and without purchasing new equipment. A truly lean-thinking solution! Working with whole batches only (no partial batches allowed), what is the required setup time in minutes, rounded to the nearest tenth of a minute, to produce the needed daily demand while keeping only three cutters on the extruder and maintaining a batch size of eight pounds?

Time per day Time per day Days per week Current Sales Target takt time Setup time (mins) Setup time (seconds) Process time (mins/donut/extruder) Process time (per batch) Setup time + Process time (per batch) Capacity (batches/day) Capacity (donuts/day/machine) Number of machines/cutters Capacity (donuts/day) Dozens cycle time Whole batches/day Capacity (using whole batches) cycle time (using whole batches) 8 hours 480 minutes 7 days 1100 doz/day 13,200 donuts/day 2.18 seconds/donut Step 1: Batching Step 2: Mixing Batch Size Donut Size Donuts/batch Change the values in the green shaded cells to see how each one of these variables affects output. Think about how changing one or more of these will affect the system as a whole. Batching2240.015,360.00115,360.001,280.001.88240Step2:Mixing2.5192.012,288.00224,576.002,048.001.17192Step3:Extruding900.061.192.69178.811,440.55953.382.52178Step4:Frying1.51.5Step5:Glazing0.750.75257.116,457.1416,457.141.7516,448.001.75Step6:Customize0.0291.867

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts