Question: Focus on 3.2 continue. Cargo operations An express package carrier carries cargo between three airports. The carrier has a certain amount of cargo carrying capacity

Focus on 3.2

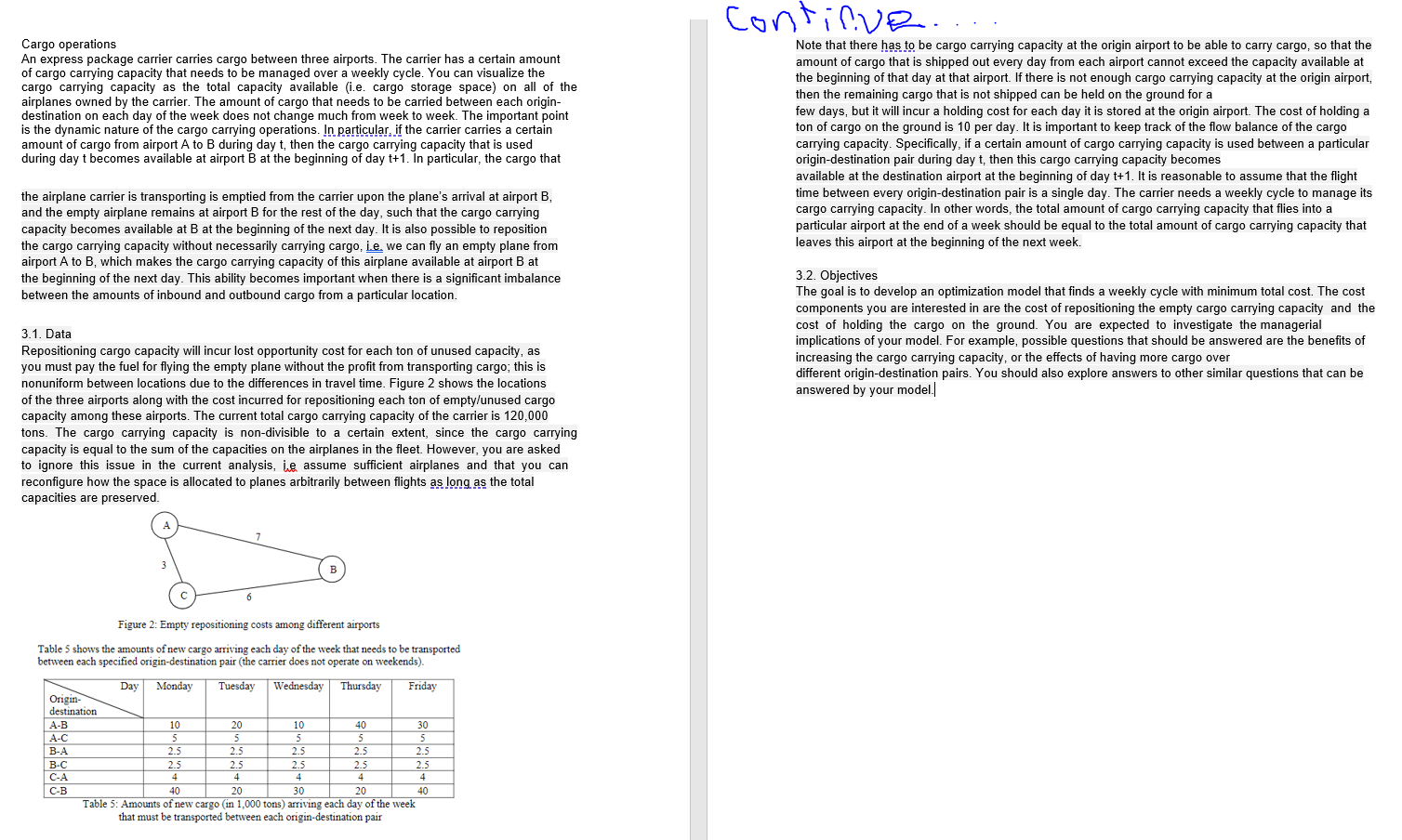

continue. Cargo operations An express package carrier carries cargo between three airports. The carrier has a certain amount of cargo carrying capacity that needs to be managed over a weekly cycle. You can visualize the cargo carrying capacity as the total capacity available (i.e. cargo storage space) on all of the airplanes owned by the carrier. The amount of cargo that needs to be carried between each origin- destination on each day of the week does not change much from week to week. The important point is the dynamic nature of the cargo carrying operations. In particular, if the carrier carries a certain amount of cargo from airport A to B during day t, then the cargo carrying capacity that is used during day t becomes available at airport B at the beginning of day t+1. In particular, the cargo that Note that there has to be cargo carrying capacity at the origin airport to be able to carry cargo, so that the amount of cargo that is shipped out every day from each airport cannot exceed the capacity available at the beginning of that day at that airport. If there is not enough cargo carrying capacity at the origin airport, then the remaining cargo that is not shipped can be held on the ground for a few days, but it will incur a holding cost for each day it is stored at the origin airport. The cost of holding a ton of cargo on the ground is 10 per day. It is important to keep track of the flow balance of the cargo carrying capacity. Specifically, if a certain amount of cargo carrying capacity is used between a particular origin-destination pair during day t, then this cargo carrying capacity becomes available at the destination airport at the beginning of day t+1. It is reasonable to assume that the flight time between every origin-destination pair is a single day. The carrier needs a weekly cycle to manage its cargo carrying capacity. In other words, the total amount of cargo carrying capacity that flies into a particular airport at the end of a week should be equal to the total amount of cargo carrying capacity that leaves this airport at the beginning of the next week. the airplane carrier is transporting is emptied from the carrier upon the plane's arrival at airport B, and the empty airplane remains at airport B for the rest of the day, such that the cargo carrying capacity becomes available at B at the beginning of the next day. It is also possible to reposition the cargo carrying capacity without necessarily carrying cargo, le we can fly an empty plane from airport A to B, which makes the cargo carrying capacity of this airplane available at airport B at the beginning of the next day. This ability becomes important when there is a significant imbalance between the amounts of inbound and outbound cargo from a particular location. 3.2. Objectives The goal is to develop an optimization model that finds a weekly cycle with minimum total cost. The cost components you are interested in are the cost of repositioning the empty cargo carrying capacity and the cost of holding the cargo on the ground. You are expected to investigate the managerial implications of your model. For example, possible questions that should be answered are the benefits of increasing the cargo carrying capacity, or the effects of having more cargo over different origin-destination pairs. You should also explore answers to other similar questions that can be answered by your model. 3.1. Data Repositioning cargo capacity will incur lost opportunity cost for each ton of unused capacity, as you must pay the fuel for flying the empty plane without the profit from transporting cargo; this is nonuniform between locations due to the differences in travel time. Figure 2 shows the locations of the three airports along with the cost incurred for repositioning each ton of empty/unused cargo capacity among these airports. The current total cargo carrying capacity of the carrier is 120,000 tons. The cargo carrying capacity is non-divisible to a certain extent, since the cargo carrying capacity is equal to the sum of the capacities on the airplanes in the fleet. However, you are asked to ignore this issue in the current analysis, ie assume sufficient airplanes and that you can reconfigure how the space is allocated to planes arbitrarily between flights as long as the total capacities are preserved. 7 B 6 Figure 2: Empty repositioning costs among different airports Table 5 shows the amounts of new cargo arriving each day of the week that needs to be transported between each specified origin-destination pair (the carrier does not operate on weekends). Day Monday Tuesday Wednesday Thursday Friday Origin destination A-B A-B 10 20 10 40 30 | A.C 5 5 5 5 5 B-A 2.5 2.5 2.5 2.5 2.5 B-C 2.5 2.5 2.5 2.5 2.5 C-A C 4 4 4 4 4 C-B 40 20 30 20 40 Table 5: Amounts of new cargo (in 1,000 tons) arriving each day of the week that must be transported between each origin-destination pair continue. Cargo operations An express package carrier carries cargo between three airports. The carrier has a certain amount of cargo carrying capacity that needs to be managed over a weekly cycle. You can visualize the cargo carrying capacity as the total capacity available (i.e. cargo storage space) on all of the airplanes owned by the carrier. The amount of cargo that needs to be carried between each origin- destination on each day of the week does not change much from week to week. The important point is the dynamic nature of the cargo carrying operations. In particular, if the carrier carries a certain amount of cargo from airport A to B during day t, then the cargo carrying capacity that is used during day t becomes available at airport B at the beginning of day t+1. In particular, the cargo that Note that there has to be cargo carrying capacity at the origin airport to be able to carry cargo, so that the amount of cargo that is shipped out every day from each airport cannot exceed the capacity available at the beginning of that day at that airport. If there is not enough cargo carrying capacity at the origin airport, then the remaining cargo that is not shipped can be held on the ground for a few days, but it will incur a holding cost for each day it is stored at the origin airport. The cost of holding a ton of cargo on the ground is 10 per day. It is important to keep track of the flow balance of the cargo carrying capacity. Specifically, if a certain amount of cargo carrying capacity is used between a particular origin-destination pair during day t, then this cargo carrying capacity becomes available at the destination airport at the beginning of day t+1. It is reasonable to assume that the flight time between every origin-destination pair is a single day. The carrier needs a weekly cycle to manage its cargo carrying capacity. In other words, the total amount of cargo carrying capacity that flies into a particular airport at the end of a week should be equal to the total amount of cargo carrying capacity that leaves this airport at the beginning of the next week. the airplane carrier is transporting is emptied from the carrier upon the plane's arrival at airport B, and the empty airplane remains at airport B for the rest of the day, such that the cargo carrying capacity becomes available at B at the beginning of the next day. It is also possible to reposition the cargo carrying capacity without necessarily carrying cargo, le we can fly an empty plane from airport A to B, which makes the cargo carrying capacity of this airplane available at airport B at the beginning of the next day. This ability becomes important when there is a significant imbalance between the amounts of inbound and outbound cargo from a particular location. 3.2. Objectives The goal is to develop an optimization model that finds a weekly cycle with minimum total cost. The cost components you are interested in are the cost of repositioning the empty cargo carrying capacity and the cost of holding the cargo on the ground. You are expected to investigate the managerial implications of your model. For example, possible questions that should be answered are the benefits of increasing the cargo carrying capacity, or the effects of having more cargo over different origin-destination pairs. You should also explore answers to other similar questions that can be answered by your model. 3.1. Data Repositioning cargo capacity will incur lost opportunity cost for each ton of unused capacity, as you must pay the fuel for flying the empty plane without the profit from transporting cargo; this is nonuniform between locations due to the differences in travel time. Figure 2 shows the locations of the three airports along with the cost incurred for repositioning each ton of empty/unused cargo capacity among these airports. The current total cargo carrying capacity of the carrier is 120,000 tons. The cargo carrying capacity is non-divisible to a certain extent, since the cargo carrying capacity is equal to the sum of the capacities on the airplanes in the fleet. However, you are asked to ignore this issue in the current analysis, ie assume sufficient airplanes and that you can reconfigure how the space is allocated to planes arbitrarily between flights as long as the total capacities are preserved. 7 B 6 Figure 2: Empty repositioning costs among different airports Table 5 shows the amounts of new cargo arriving each day of the week that needs to be transported between each specified origin-destination pair (the carrier does not operate on weekends). Day Monday Tuesday Wednesday Thursday Friday Origin destination A-B A-B 10 20 10 40 30 | A.C 5 5 5 5 5 B-A 2.5 2.5 2.5 2.5 2.5 B-C 2.5 2.5 2.5 2.5 2.5 C-A C 4 4 4 4 4 C-B 40 20 30 20 40 Table 5: Amounts of new cargo (in 1,000 tons) arriving each day of the week that must be transported between each origin-destination pairStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock