Question: For how many SCOR Level 3 processes is this a best practice? [ page 3.2.109 of the Full reference model ] Vendor Managed Inventory (VMI)

For how many SCOR Level 3 processes is this a best practice? [ page 3.2.109 of the Full reference model ]

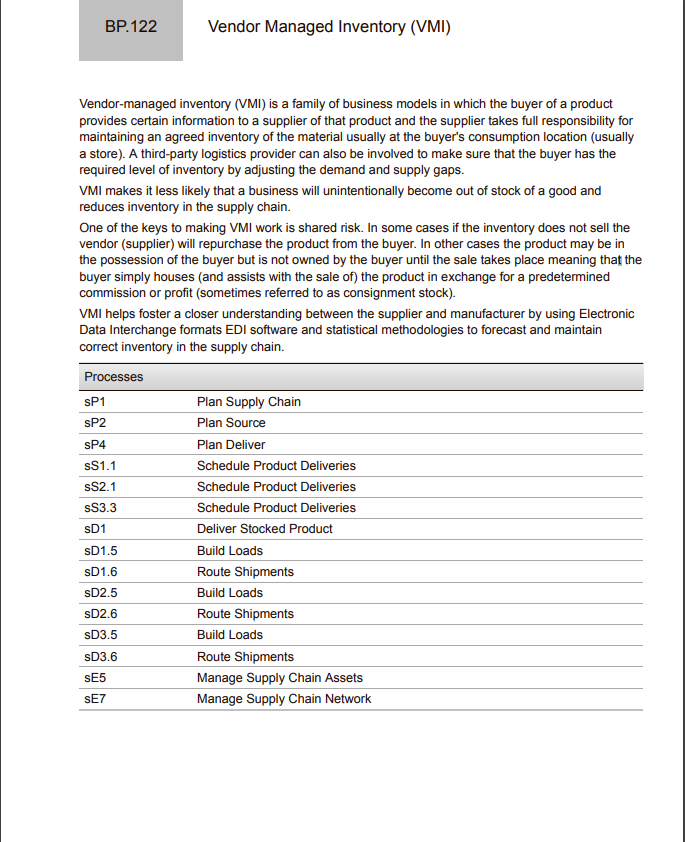

Vendor Managed Inventory (VMI) Vendor-managed inventory (VMI) is a family of business models in which the buyer of a product provides certain information to a supplier of that product and the supplier takes full responsibility for maintaining an agreed inventory of the material usually at the buyer's consumption location (usually a store). A third-party logistics provider can also be involved to make sure that the buyer has the required level of inventory by adjusting the demand and supply gaps. VMI makes it less likely that a business will unintentionally become out of stock of a good and reduces inventory in the supply chain. One of the keys to making VMI work is shared risk. In some cases if the inventory does not sell the vendor (supplier) will repurchase the product from the buyer. In other cases the product may be in the possession of the buyer but is not owned by the buyer until the sale takes place meaning that the buyer simply houses (and assists with the sale of) the product in exchange for a predetermined commission or profit (sometimes referred to as consignment stock). VMI helps foster a closer understanding between the supplier and manufacturer by using Electronic Data Interchange formats EDI software and statistical methodologies to forecast and maintain correct inventory in the supply chain

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts