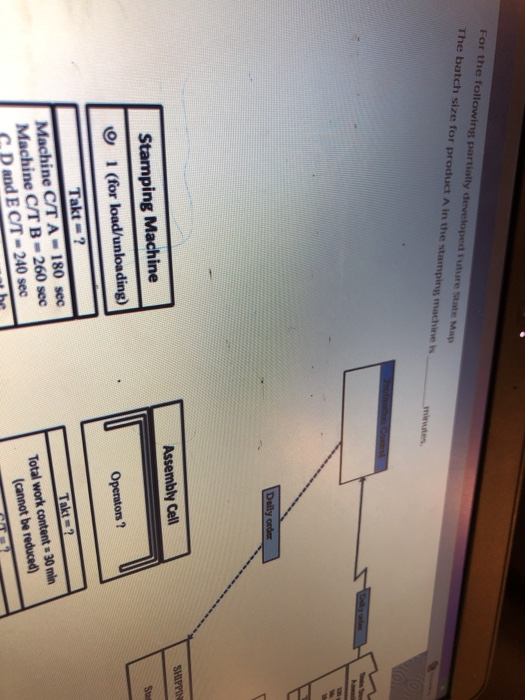

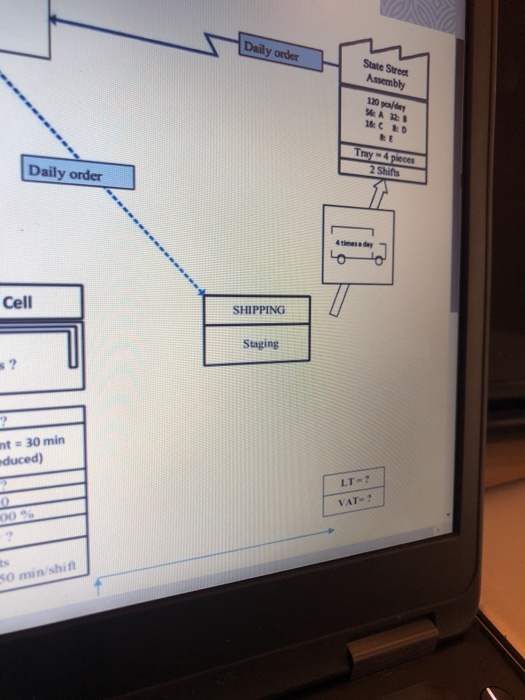

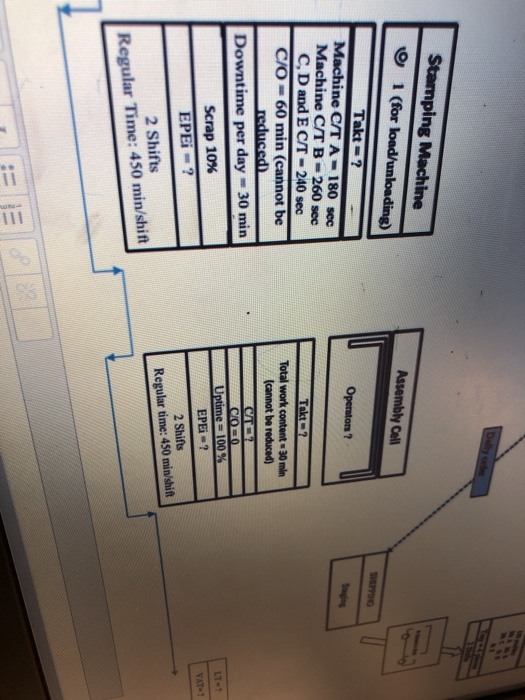

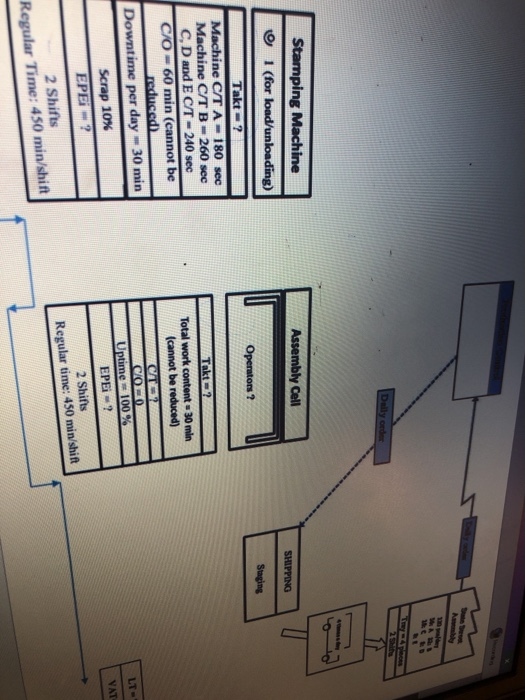

Question: For the following partially developed Future State Map The batch size for product in the stamping machines Dully orde SHIPPON Assembly Cell Sur Stamping Machine

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock