Question: For this problem I ' m supposed to iteratively try different X positions in steps from 0 to 1 to find the max thickness that

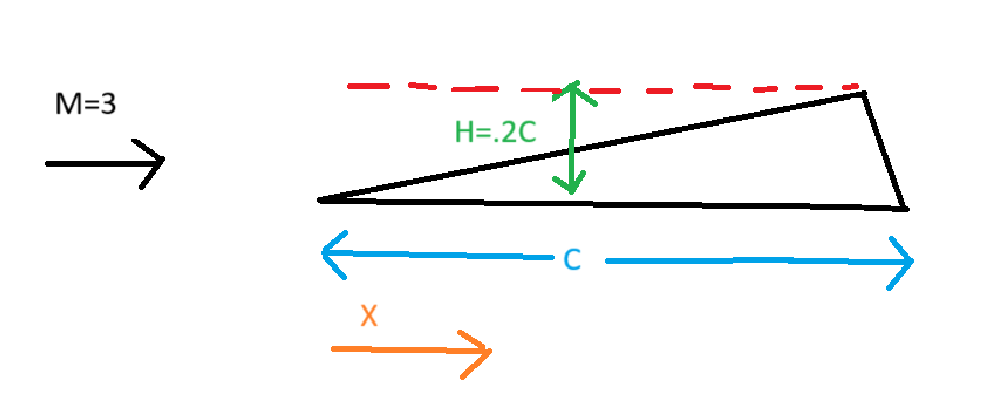

For this problem Im supposed to iteratively try different X positions in steps from to to find the max thickness that gives the max lift on an airfoil I also need to find the thickness that gives the least drag. The first picture is given where, M is mach H is the max thickness, and c is the chord length. The following pictures and process is my rough understanding of how to solve itPicture shows the general setup of the table that will tabulate the lift and drag for each x value Since Mthis is supersonic flow so there are shocks present. Because of this I need to obtain the angle Beta. First I obtained theta for x by basic trig shown in picture and then used the Theta, Beta, Mach Chart to get Beta for weak shock. This came out to be degrees However I don't remember the process to solve after getting beta. I think you have to solve for the different pressures and I know you have to use the compressible flow tables. Then you plug the asssociated values into the lift and drag equations to get the answers. Picture better illustrates the shocks. In picture I vaguely remember combining the pressures to get a resultant force. Any help would be appreciated as I read my textbook and it isnt of any help for this problem.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock