Question: from part d to end please 1. Business Case for Eco-Design and Sustainable Manufacturing Review the article Making the Business Case for Eco-Design and Sustainable

from part d to end please

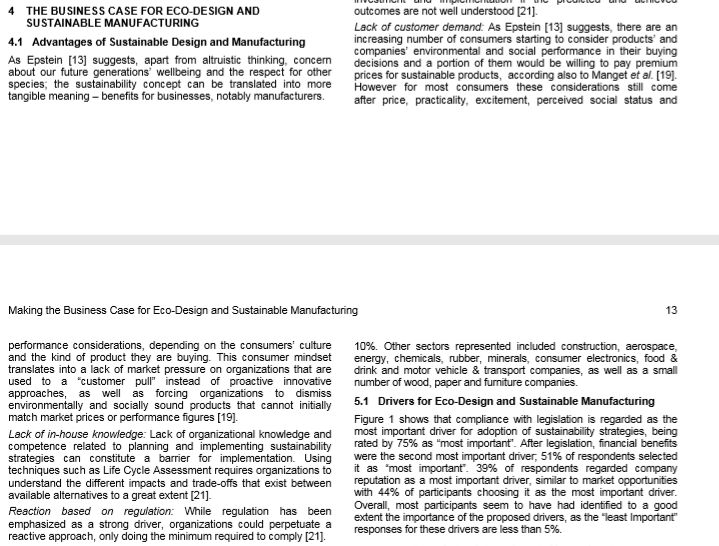

1. Business Case for Eco-Design and Sustainable Manufacturing Review the article "Making the Business Case for Eco-Design and Sustainable Manufacturing.pdf, posted in canvas in Modules -> Feb 28, 2019 Class, and answer the following questions: a. Define "eco/sustainable product design". b. Define "sustainable manufacturing". c. List three sustainable manufacturing strategies, and briefly explain how each strategy could contribute to sustainability. d. For the studied companies, what are the top three drivers for eco- design and sustainable manufacturing? e. What are their top three barriers? f. What are the top three eco-design strategies? g. What are the top three sustainable manufacturing strategies? h. How does "Sustainable Performance" rank among the Supplier Selection Criteria? i. Based on the discussions and conclusions provided by the authors, what is your explanation for the reasons for their ranking Abstract The results of a survey conducted among more than 150 UK manufacturing companies identify key drivers, barriers and alternative strategies for managing eco product design and sustainable manufacturing - developing a stronger business case for the move towards more sustainable design and manufacturing. The survey results showed that while high implementation costs, weak justification for investment, lack of stakeholder awareness and weak customer demand are major barriers; compliance with future legislation, risk reduction, improved company reputation and long term financial benefits are the main drivers for manufacturers - making the case to more widely adopt eco design and more sustainable manufacturing Keywords: Eco-Design; Sustainable Manufacturing, Survey; Drivers, Barriers; Strategies the needs of customers, communities and businesses [2] Eco design is based on the principles of minimizing the use of energy sources and materials, and reducing resource consumption, through de-materialisation of services as discussed by [2], [5] & [6] 2.2 Sustainable Product Design Strategies Sustainable design strategies aim to apply the above principles and build on eco design strategies, to address the economic, social and environmental pillars of sustainable development. There are several alternative strategies for eco product design and development that can be employed as discussed and compared by [7], [8], [9] & [10]. 1 INTRODUCTION Our environment is showing signs of stress from our unsustainable models of production and consumption raising concerns about future generations and other species' long term ability to survive. Businesses play an important role in our society's sustainability: providing the products and services that sustain our way of life, contributing to the economy, creating employment and subsidising governments. It is evident that many industrial processes and their resulting products, by products and waste, have negative impacts on the environment; being directly related to environmental pollution and public health issues, and intensively consuming non-renewable energy, water and materials. However, as the link between environmental performance, social responsibility and financial performance have become more evident, businesses are starting to identify how these aspects interact in affecting their operations and profitability. Pursuing sustainability strategies as a source of competitive advantage is increasingly accepted. Successful cases of the integration of sustainability within business strategies are spreading (1) Sustainable design and manufacturing concepts respond to the specific and growing awareness of the environmental impacts of products through their whole lifecycle and to managers change of mindset, moving from mitigating environmental and social impacts to preventing them (2]. This paper reviews literature on eco design and sustainable manufacturing and analyses the results of a UK survey conducted to identify the main drivers and barriers as seen by senior managers in manufacturing industry. The paper concludes with a set of recommendations for developing strategies for eco-design and sustainable manufacturing and managing them in small or medium- sized enterprises (SMEs), where a business case is most needed. 3 SUSTAINABLE MANUFACTURING 3.1 Definition and Principles Sustainable manufacturing can be defined as the creation of goods or services that satisfy customer needs while respecting the environment and communities' wellbeing (11]. It aims to integrate sustainability into manufacturing activities, seeking a balance between financial, social and environmental factors through the optimization of resource use, social value and environmentally responsible practices (11). Sustainable manufacturing goes beyond the product view and factory limits to address how the manufacturing related facilities interact with the environment and communities, at all product lifecycle stages from extraction to disposal and recovery. This could be in terms of by-products, waste, energy use, employee and customer health and safety, community involvement, supplier development, transport or ancillary materials e.g. those used for packaging, among many other areas [12]. Further discussion of the principles of sustainable manufacturing and their applications can be found in (13), (14] & [15] 3.2 Sustainable Manufacturing Strategies JUJUI TUTUKUw my w orror sized enterprises (SMEs), where a business case is most needed. 2 ECO / SUSTAINABLE PRODUCT DESIGN 2.1 Definition and Principles Sustainable design is a design approach based on considering the social, environmental and economic performance of a product over its lifecycle (3). Considering sustainability in product design, mostly focussing on environmental aspects, has resulted in various approaches, typically termed 'eco-design (more popular among organizations and the public than 'sustainable design [4]). Sustainable design applies the following principles, aiming to taking into consideration the economic, social and environmental performance of products and services through their whole lifecycle and accounting for the existing interactions and tradeoffs between these three areas, while seeking a synergy between them to satisfy 3.2 Sustainable Manufacturing Strategies According to Olsen [16], in the 1980s, sustainability strategies were reactive, aiming to address 'effects rather than "causes', with the only concern being complying with regulations and reducing liabilities, achieving limited impact-reduction mostly related to compliance. Nowadays, the following strategies towards sustainability have benefitted from a proactive approach, aiming to look at the root cause of the unsustainable aspects in organizations and the impacts attributable to the whole product lifecycle [13] Promote transparency and ethics: Implement a well delineated transparency and ethics policy for dealing with stakeholders, based in fairness, equality and transparency. Organizations should clearly respect human rights, diversity and adhere to trade, health, safety and labour laws, as well as recognizing accountability on environmental health and social issues to the public and disclosing information about past, present and future expected performance to stakeholders (13) 19th CIRP International Conference on Life Cycle Engineering, Berkeley, 2012 A Veshagh, S. Marval, and T. Woolman Innovation and re-engineering Promote innovation and re- engineering of business processes, products and practices to adapt to the changing environment businesses operate in seeking to create new ways to satisfy needs with improved sustainability performance (12]. Manage organizational knowledge: Organizations should aim to retain explicit and tacit knowledge in order to support innovation and reengineering aimed towards sustainability performance. This includes applying lessons leamed, managing tradeoffs between sustainability aspects, pursuing best practices, recognising success factors and mitigating risks in processes (17]. Create a safe and healthy working environment: Create a safe and healthy working environment and minimize occupational health risks for emnlovees local communitieustomers and supliers 141 Compliance with regulations and risks reduction: Non-compliance with regulatory controls on environmental and social performance could translate into operational and financial risks, such as penalties, legal costs, regulators stopping company operations and loss of productivity due to further inspections and the implementation of special measures. Poor Sustainability performance can also be regarded as a risk factor by investors, translating into increased insurance costs and difficulties in obtaining financial support(1). Failing to comply with environmental and social regulations could prevent doing business in certain markets or winning contracts [13] Resilience to external pressures: Pursuing sustainability strategies could improve firms resilience to external pressures, such as variations in fossil fuel and raw material prices [13] ciding the cor renewabnd conservi reduct comme company culputation will prom ce raw material Dufacturing processos ered either from Tactors ana mitigaung risks in processes [11] Create a safe and healthy working environment: Create a safe and healthy working environment and minimize occupational health risks for employees, local communities, customers and suppliers (14) Support employee and community development Employees should be empowered, trained and supported in their personal and community development endeavours, while at the same time organizations should be approachable and aim to partner with communities to respond to their needs and establish healthy relationships (13) Cleaner production: Production should aim to prevent environmental damage, focusing on prevention rather than remediation. For example, by avoiding the use or generation of toxic substances or by-products, using cleaner or renewable energy sources, improving process efficiency, minimizing waste and conserving resources such as raw materials, energy, water and land, through reduction, reuse and recycling initiatives, optimizing transport, manufacturing processes, packaging and resource efficiency [18]. Closed loops and reverse logistics: Closed loop strategies aim to use materials and components that have been recovered either from the market, other internal manufacturing processes or suppliers, in order to reduce raw material extraction or prevent substances from degrading or polluting while in contact with the environment (14) Reverse logistics is making the materials flow back to the manufacturing operation after their use ends (18]. Supply chain integration and assessment: Supporting the product life-cycle view, it is desirable to integrate supplier's performance aims with those of the organization's operations, by promoting collaboration and shared data gathering to help understand sustainability impacts and gain control over liabilities down the supply chain (14). Selecting the transport & logistics options with the least resulting pollution while still maintaining customer service levels and lead times can also be linked to this strategy (19]. Seek product and process certification: Certification can serve as guidance for improving sustainability performance as well as supporting marketing initiatives to gain entry to new markets. Moving towards a service business model Offering on-going product service systems (PSS) rather than selling products, can reduce resource intensity, as well as improving resilience to adverse market conditions and create new business opportunities Since every organization operates in a particular environment, with its own pressures and constraints, the above set of strategies, cannot be easily applied as a "one size fits all model for change (10). Each organisation resolves their balance of the benefits foreseen and achieved against the barriers they face, considering the business case eco/sustainable design and manufacturing Resilience to external pressures: Pursuing sustainability strategies could improve firms resilience to external pressures, such as variations in fossil fuel and raw material prices [13] Improved financial performance: Since sustainability strategies promote more efficient utilization of resources, they promote cost reductions while reducing operational and financial risks (1) Sustainability strategies also promote innovation and differentiation, which could also translate into improved market prospects [13] Improving company reputation and stakeholder relationships Improving company reputation will promote customer loyalty and a healthy company culture, enhancing employee motivation and commitment to the organization [1] It also contributes to attracting the best talent and reducing the risks of labour conflicts [12]. A good sustainability reputation also benefits the licensing of operations, contract adjudications and community acceptance [20] Market opportunities and competitive advantage: Apart from targeting a growing number of sustainability conscious customers (13), building relationships with communities will help to identify their needs and find profitable business opportunities from new products and related services. Sustainability strategies also imply positive change within organizations, promoting rethinking, reengineering, continuous improvement, innovation and competitive advantage [21). Companies could seek to exploit "first mover advantage to better position themselves for future competition 4.2 Barriers to Sustainable Design and Manufacturing While there appear to be compelling reasons why companies should pursue sustainability strategies in the design and manufacture of their products, there are often barriers to their implementation which limit achievements (13]. A summary of barriers identified for implementing sustainable design and manufacturing implementation is provided below. High implementation cost: Sustainability strategies in a product design and manufacturing business can be associated with high implementation costs and long payback times, as they could require investments in the acquisition or development of new technologies, infrastructure improvements and organizational restructuring Unclear justification for investment: While the financial benefits of sustainability strategies have been recognized by many organizations, sustainability initiatives can be perceived to offer weak financial incentives if the link between financial benefits and measures towards long term sustainability is not clear, making difficult the granting of longer term financial support, as many companies tend to focus on solving short term issues [21] Moreover, addressing environmental and social issues can be seen in some cases as charitable, public relations actions, instead of business imperatives, compromising stakeholders' support for investment and implementation if the predicted and achieved outcomes are not well understood (21) blic relational issues ssues many 4 THE BUSINESS CASE FOR ECO-DESIGN AND 4 THE BUSINESS CASE FOR ECO-DESIGN AND SUSTAINABLE MANUFACTURING 4.1 Advantages of Sustainable Design and Manufacturing As Epstein [13] suggests, apart from altruistic thinking, concern about our future generations' wellbeing and the respect for other species, the sustainability concept can be translated into more tangible meaning - benefits for businesses, notably manufacturers. outcomes are not well understood (21). Lack of customer demand: As Epstein (13) suggests, there are an increasing number of consumers starting to consider products and companies' environmental and social performance in their buying decisions and a portion of them would be willing to pay premium prices for sustainable products, according also to Manget et al. (19) However for most consumers these considerations still come after price, practicality, excitement, perceived social status and Making the Business Case for Eco-Design and Sustainable Manufacturing performance considerations, depending on the consumers' culture and the kind of product they are buying. This consumer mindset translates into a lack of market pressure on organizations that are used to a "customer pull" instead of proactive innovative approaches, as well as forcing organizations to dismiss environmentally and socially sound products that cannot initially match market prices or performance figures (19) ack of in-house knowledge Lack of organizational knowledge and competence related to planning and implementing sustainability strategies can constitute a barrier for implementation. Using techniques such as Life Cycle Assessment requires organizations to understand the different impacts and trade-offs that exist between available alternatives to a great extent [21]. Reaction based on regulation: While regulation has been emphasized as a strong driver, organizations could perpetuate a reactive approach, only doing the minimum required to comply [21]. 10%. Other sectors represented included construction, aerospace, energy, chemicals, rubber, minerals, consumer electronics, food & drink and motor vehicle & transport companies, as well as a small number of wood, paper and furniture companies. 5.1 Drivers for Eco-Design and Sustainable Manufacturing Figure 1 shows that compliance with legislation is regarded as the most important driver for adoption of sustainability strategies, being rated by 75% as "most important. After legislation, financial benefits were the second most important driver, 51% of respondents selected it as 'most important. 39% of respondents regarded company reputation as a most important driver, similar to market opportunities with 44% of participants choosing it as the most important driver. Overall, most participants seem to have had identified to a good extent the importance of the proposed drivers, as the least Important responses for these drivers are less than 5%. Technology avaly The technology required to reduce the environmental Impact of products may not exist or be too complex or unreale at the moment Lack of supply chain accountability. As sustainability strategies need to account for the whole Ifecycle of the product, sustainable design and manufacturing strategies require support from the supply chain [10). Whether through ok of knowledge, concem, capacity or feeling of responsibility for environmental and social impacts, not all suppliers engage with sustainability strategies - a major Inconvenience the choice between suppliers is limited (16]. Time constraints. Since the benefits of Implementing more sustainable business strategies are usually long term. It is aimcult to sustain internal and external support, in terms of both financial investment and motivation for change, especially when organizations need to address shorter term issues that are more easily related to rewards from the bottom line 21 Figure 1: Drivers for Eco-Design and Sustainable Manufacturing 5.2 Barriers to Eco-Design and Sustainable Manufacturing Figure 2 shows the importance ratings given to a set of proposed barriers by respondents High Implementation costs or long payback time was regarded as the most important barrier for the adoption of sustainabilty strategies, with 82% of the participant companies ranking It as either most important or important Lack of stakeholder awareness was perceived as the second most important barrier, 72% of the participants perceived it to be either most important (28%) or important (44%) followed by the lack of stakeholder awareness which 69% of the participants rated as most important or important. Lack of in house expertise was regarded as the least important barrier being rated inportant (29%) or most important (9%) by 48% of participants Bresciando 5 SURVEY OF UK MANUFACTURING COMPANIES Research work on eco design and sustainable manufacturing has been undertaken in Warwick Manufacturing Group at the University of Warwick's international Manufacturing Centre, for over a decade. The resurs of several surveys oonducted with SMEs in automotive and manufacturing industries have been published [22) 1231. 124) & [25). A new questionnaire was designed and tested for the purpose of the research reported in this paper, building on previous studies (26) The survey was conducted in 2011 among a range of manufacturing businesses in the UK in order to compare the above findings from reviewing literature with industry's perception of the drivers, barriers, benents and naks of sustainable design and manufacturing. The survey aimed to provide an insight into the changes needed and the implementation plans for more sustainable design and manufacturing as well as areas where business may need extemal support. The survey using a questionnaire was conducted through both by email and through personal Interviews. Survey Analysis 158 survey responses were collected, of which 61 responses were self-selecing emal respondents. The UK Office of National Statistics reported 183.510 VAT registered manufacturing business in the UK in 2008, representative of the total population A confidence interval for the percentage results as proportions of the survey respondents was calculated as 7.8% at a 95% confidence level. Participating Companies 41% had between 51 to 250 employees 25% between 251 10 100 employees and 21% had less than 50 errployees, companies with more than 1000 employees were the lowest proportion participating at 13%. Regarding the industry sectors represented, companies that manufacture machinery, equipment and Instruments had the largest participation accounting for $3%, while companies in the metal materials manufacturing sector accounted for Figure 2 Barriers for Eco-Design and Sustainable Manufacturing 5.3 Strategies for Eco-Design and Sustainable Manufacturing Figure 3 shows that design for reduced use of resources is the most widely used strategy among the participating companies, accounting for 76% of responses. Strategies involving design for recycling reuse or remanufacturing is the second most widely used sustainable design strategy accounting for 65% of responses closely followed by design for reduced pollution and emissions (59%) and design for longer inte (56%). Only 9% of the participants weed other design strategies and significanty only 3% of companies have not adopted any eco-design strategy Eco-design Strategies 5.5 Sustainability Goals and Objectives Figure 5 shows that measuring the environmental footprint of their products and processes was the most popular sustainability goal accounting for 74% of responses while training employees suppliers or clients on sustainability was the second most popular goal (66%). The third and fourth most popular goals among the surveyed organizations were verying the supply chain social performance 32%) and moving towards a service business model (25%) respectively. The proportion of participant business that did not have any sustainability goal was 6%, while 1% of the participants Identified other sustainability business goals, such as seeking certification to ISO environmental or quality standards Sustainability Goale Responses (94) Responses D-Design for Larger Le A-Design for Reduses Ressurse U B. Denge for a Reuse - Verly 100 ya TANES Figure 5: Sustainable Manufacturing Strategies - Denn for Resues F - No Sur Dung Suges Poniga Figure 3: Eco-Design Strategies. 5.4 Sustainable Manufacturing Strategies Figure 4 shows that there are two predominant sustainable manufacturing strategies being implemented among the participating organizations, these are the strategies of using less raw materials and energy (81%), and the strategy of reducing waste and adopting cleaner production 79%). The strategy of utilizing sustainable, renewable materials and engwania materials and resources the third most widely used (53%) and product stewardship, reverse logistics and closed loops strategies ranked fourth (25%). The proportion of participating companies that have not adopted any sustainable manufacturing strategies accounted for 3% of the responses Sustainable Manufacturing Strategies Figure 6 shows the importance participants cave to a set of proposed suppler selection arteria uring a score from 1 to 4 as part of their sustainability strategies, CO was regarded as the most Important criteria with a mean score of 3.47 / 4 followed by flexibility to meet new needs (2004 ), leaving suppler's sustainability performance as the least important orttera atter long term relationship building, with an importance score of 2.46 / 4 Supoter Section C ertimportance Average Responses Figure 6: Supplier Selection Criteria Importance Average 6 DISCUSSIONS AND CONCLUSIONS 6.1 Driver, Barriere, Benefits and Risks for Eco-Design and Sustainable Manufacturing The survey results suggest that product design and manufacturing businesses in the UK recognise the important contribution of eco- product design to their longer term sustainability in common with The findings of the literature review the survey shows manufacturing businesses appear to be driven primarily by the need to comply with regulation and reduce sks. The results also suggest that legal or seen as the most important raks, as well as the most important benefit from Implementing sustainabilty strategies Athough achieving financial benefits was the second most important driver for adopting sustainable design and manufacturing strategies (congruent with the interature): it is important to notice that the most Important barrier for adopting sustainable design and manufacturing strategies are high implementation co18 or long payback times This Imples that while companies might see sustainability strategies as a way to improve their financial performance they might not be able or willing to make the investment required for implementation This Is reinforced by weak Justification for investment appearing as the second most important barrier for the adoption of sustainability strategies in the survey Weak station for investment is perhaps related to the lack of stakeholder awareness ranking as the second most important barrier in the survey implying that the companies surveyed might not be facing strong customer demand of stakeholder support to Implement sustainable products or processes of might have not Idensed a strong business case for Sustainablity to justify their Investment in sustainability strategies, through benefits including enhanced company reputation or ik reductions. Literature similarly suggests that while there might be growth in sustainability conscious customers, in many cases customers would not be willing to pay premium prices or give up product features in exchange for a more sustainability oriented product, also that suppliers might not yet feel accountable for their unsustainable practices. On the other hand, as suggested in the literature seeking enhanced company or brand reputation proved in the survey to be an important diver for sustainable design and manufacturing, being perceived as a major benent. Competitive advantage and innovation, though ranked in the survey as an important driver, stii comes after other drivers and perceived benets such as regulatory compliance, financial benefits or enhanced reputation. This suggests that the importance attributed to differentiation through improved environmental or social performance as a source of competitive advantage, 16 still subordinated to other priorities in UK manufacturing These results suggest that while some companies have identified the financial benefits they can obtain from sustainable design and manufacturing strategies, a number of companies engage with sustainability strategies without knowing the exact performance benefits they might obtain from their investment. This is Understandable as a result of estimating the market Opportunities and competitor pressures-ranked as the fourth most important driver for sustainable design and manufacturing, at a similar level to enhanced reputation. It can be intered that some companies might Invest in sustainability strategies to keep up with competitors and to promote their brand even the business case for sustainability net weil dered or the link between the sustainability strategies ang frangal bereits not explicity related to brand image or marketing The supports the suggestion from the literature that engaging with sustainability strategies is being regarded just as a public relations or charity oriented exercise The results of the survey regarding the benefits and drivers for sustainable design and manufacturing are broadly consistent with the iterature reviewed here. suggesting that among the growing number of companies which are engaging with sustainability strategies, there are O Subgroups. One group would invest in sustainability strategies aiming to get a retinover advantage and trying to achieve an enhanced, competitive company reputation by developing sustainable products and operations trying to exceed regulation requirements (even if future regulation or the justification for Investment is unclear, le taking a leap of faith). A second group of companies is more cautious, engaging in sustainability strategies as a result of Ourrent or clearly defined future regulation and or market pressures created by the first group Overall, it is noticeable that the highest perceived business risks from inancial and social concerns are directly related to the highest ranked drivers and benents in the survey. Possible legal or financial risks or liabilities, the highest ranked risk in the survey, is directly Inked with the regulatory comprance driver, while possible damage to reputation, ranked the second most important risk in the survey, 16 also directly linked to enhanced company reputation and stakeholder relationship, one of the most important perceived beness and drivers. The risk of being closed to certain markets also relates to both compliance with regulation in suo markets and to company reputation, the later being regarded as the third most Important business risk Wile the lack of know-how or in-house expertise proved to exist as a barrier for implementing sustainable design and manufacturing strategies, I was not regarded by companies as having as much importance as that suggested in the iterature, since it was ranked fourth among the proposed barriers in the survey, with the highest proportion of low importance ratings Contrasting with the findings of the terature review the possible tuture navality of raw materials or energy, though it was den ned as a business risk, did not achieve in the survey the Importance suggested in the merature. This might be explained as the surveyed companies not perceiving raw material supply as a problem in the short term-a contrast with views from the iterature suggesting sing energy prices should be seen as importants 6.2 Sustainable Design and Manufacturing Strategies The survey results suggest that most of the sustainable design strategies Implemented by companies tend to be focused towards environmental compliance and cost reduction. The most popular strategies adopted by businesses are the reduction of materials, energy use and pollution, also recycling strategies in which financial benefits in the form of cost reductions and risk reductions are easily Identifiable Although design for recycling seems to be a popular design strategySustainable manufacturing strategies that support recycling, such as reverse logistio and closed loops, do not appear to be as popular, according to the survey results. These results suggest that even though products are being designed to be recycled and in some industry sectors regulation acts as a strong driver for recycling), the actual royaiing or recovery of products, sub-products or packaging might not be taking place with the same effectiveness. These manufacturing strategies also require support from stakeholders for the recovery of products at the end-of- Similar to the preferences for sustainable design strategies identified in the survey, the sustainable manufacturing strategies implemented by the participating companies tend 10tus on reducing the amount of raw material and energy used, reducing waste and engaging cleaner production methods. Again cleaner productions driven by regulation and risk reduction while material and energy we reductions are possy being driven by francial benefits from cost saving in general terms, the approach towards sustainability seere to be aimed towards Improving technology and processes and adopting environmental management systems or standards: seeking a synergy between environmental and financial performance with perhaps lesser regard for social sustainability performance. This lack of attention to the social component of sustainablity strategies is evidenced in the low percentage of respondents (31%) selecting the verification of social performance in their supply chain as a company goal, while the goal of measuring the environmental footprint of company's products was chosen by 74% of respondents Even though the surveyed businesses seem to have an integrated approach towards sustainabilty training employees, suppliers and a lents on sustainability was the second most popular goal among participants (66%), when it comes to supplier selection arteria, the verification of supplier sustainablity performance was still the feast Important arteria identified, supply costs and nexibility to meet business or operational needs were the priority, which implies a contradition between the ambition to train suppliers towards achieving sustainability in the supply chain and actually assessing their sustainablity performance to make sourcing decisions 20cordingly. The goal of moving towards a product service system business inadel instead of a product sales business model, also achieved a lower popularity than other goals (27%), in common with closed loop strategies, PSS depends on the customer mindset to a great extent, since it implies a change in consumption patterns The business case for eco-design and sustainable manufacturing hence becoming clearer for some manufacturing businesses while me majority have yet to go beyond compliance and cost saving to translate their wareness and a n into hot and competitive approaches Support for businesses responding to these drivers clearly needs to retain a fool on maintaining and enhancing the compliance with developments in environmental regulation Justication for Investment in more proactive sustainability strategies needs to be made more tangible in relation to the present value of enhancing reputation and reducing business niks, particularly reflecting the specific business conditions in a particular sector an integrated approach towards sustainability, reflecting the sources of short and longer term value in all areas of the organization is needed to gain embed change rather than focusing on function-specific environmental issues. Establishing such a strong and tailored business case for sustainability is considered necessary for the aceptance of change towards Sustainability strategies and managers gaining support for their succesul implementation Since high implementation costs and lack of stakeholder or customer support were identined as important barnens for implementing sustainable design and manufacturing strategies further work on valuing alternative options to address these barriers in areas such as marketing and advertising of sustainable products to achieve both stakeholder support and customer demand well a predicting the cost-benefits of operational practices aimed to sustainability would be beneficial The high implementation cost barrier is related in most companies to technology and infrastructure charge to improve environmental performances. This typically the main point to address when manufacturers are looking to become more sustainable. Therefore further research into both environmental trendy technologies which are financial competeve, as well as non-technology based abernatives to address sustainably priormes would be beneficial The reputation of sustainability strategies being regarded as a charitable strategy bouid also be adressed to ensure organizations approach all peotic aspects of Justication holistically collating benefits to respond to drivers and barners Oros al areas where strategies could be applied and yield results Therefore, studies aiming to enable and demonstrate change management toward the often challenging and diverse Implementation of sustainability strategies specifically in smaller manufacturing businesses, would be beneficial The authors welcome contact with those who are pursuing eco design and sustainable manufacturing, both within their companies and or through business support organisationsStep by Step Solution

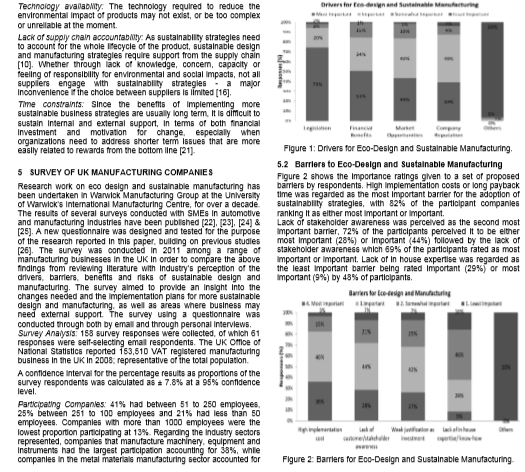

There are 3 Steps involved in it

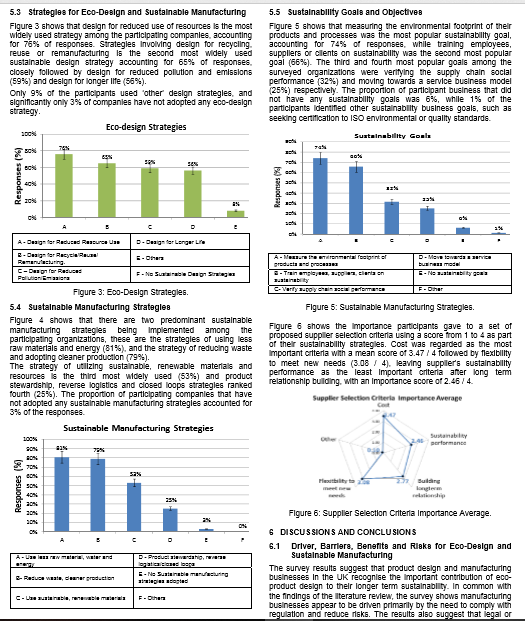

1 Expert Approved Answer

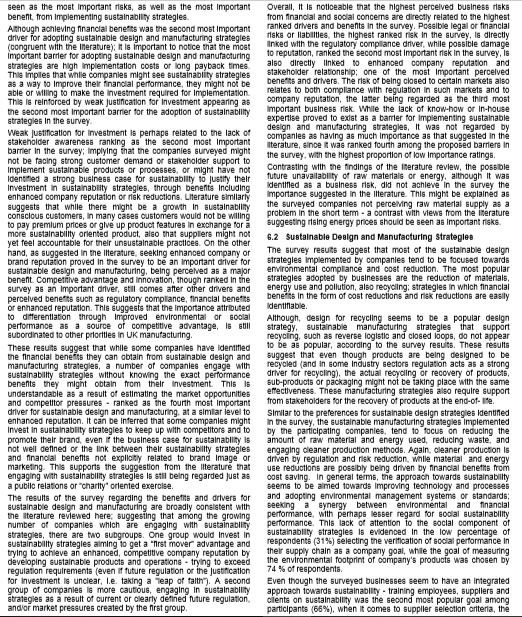

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock