Question: Full Throttle orders a key part from an external supplier and needs to determine the optimum ordering plan for the next 5 weeks. The parts

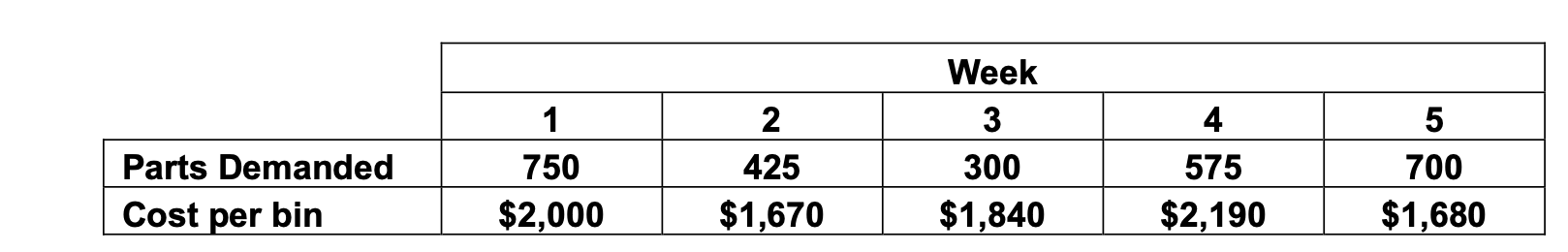

Full Throttle orders a key part from an external supplier and needs to determine the optimum ordering plan for the next 5 weeks. The parts are ordered in bins that contain 200 parts per bin. They can order up to 4 bins per week. The planning team estimated the demand of parts of the next 5 weeks and the supplier gave them the following cost per bin for the next 5 weeks.

They currently do not have any parts on hand and will incur a carrying cost of $7.50 per part based on average inventory.

Develop an Excel model and solve using Solver to find their optimum ordering strategy.

1 750 $2,000 Parts Demanded Cost per bin Week 3 300 $1,840 2 425 $1,670 4 575 $2,190 5 700 $1,680 |Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts