Question: GFA has a contract with four local cities to acquire the compost that is recycled by city residents. GFA only pays for transportation from

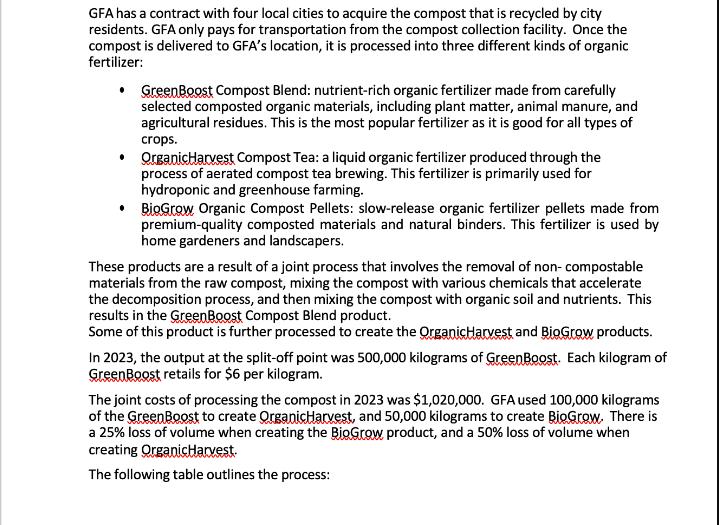

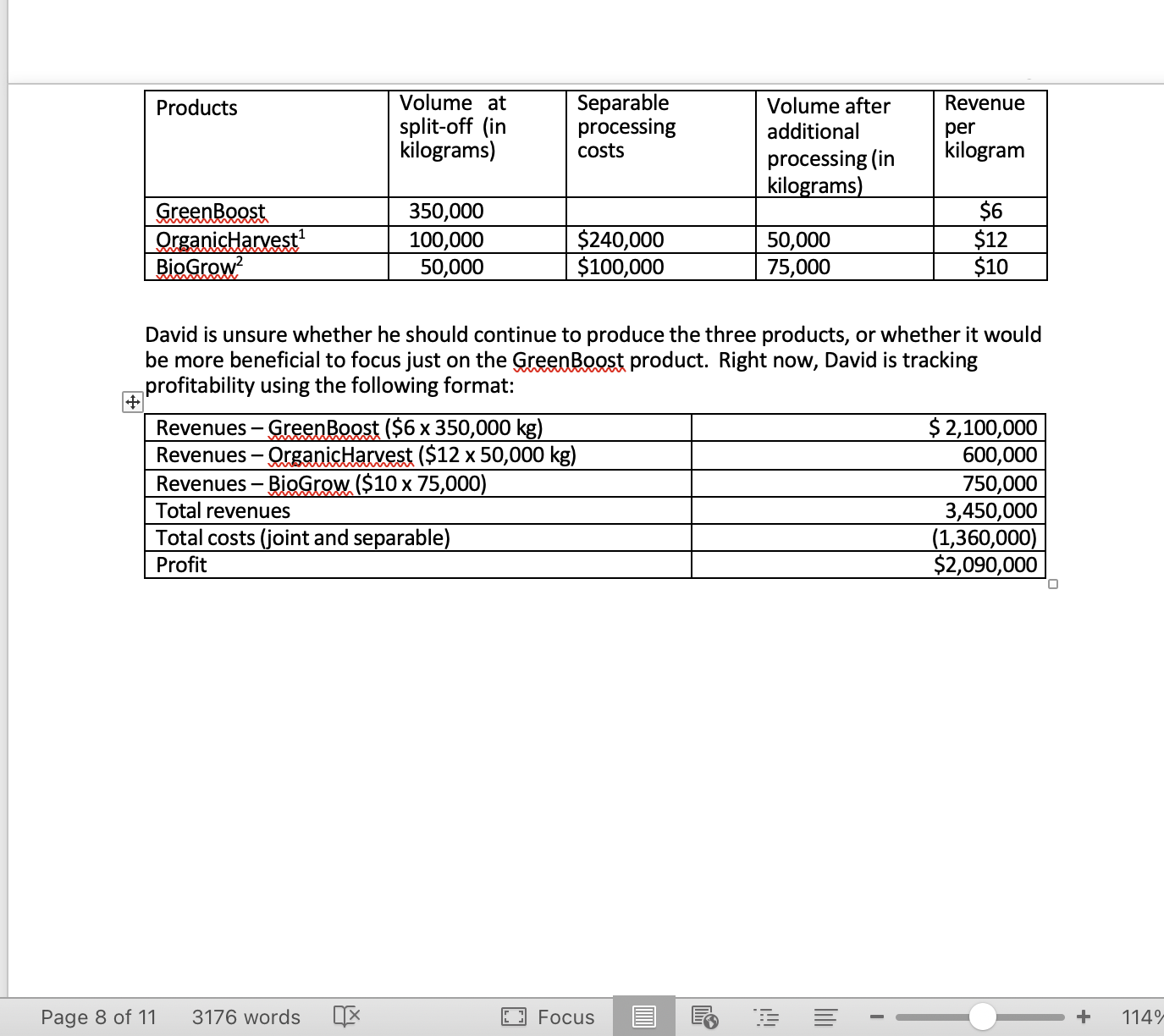

GFA has a contract with four local cities to acquire the compost that is recycled by city residents. GFA only pays for transportation from the compost collection facility. Once the compost is delivered to GFA's location, it is processed into three different kinds of organic fertilizer: GreenBoost Compost Blend: nutrient-rich organic fertilizer made from carefully selected composted organic materials, including plant matter, animal manure, and agricultural residues. This is the most popular fertilizer as it is good for all types of crops. OrganicHarvest Compost Tea: a liquid organic fertilizer produced through the process of aerated compost tea brewing. This fertilizer is primarily used for hydroponic and greenhouse farming. BioGrow Organic Compost Pellets: slow-release organic fertilizer pellets made from premium-quality composted materials and natural binders. This fertilizer is used by home gardeners and landscapers. These products are a result of a joint process that involves the removal of non-compostable materials from the raw compost, mixing the compost with various chemicals that accelerate the decomposition process, and then mixing the compost with organic soil and nutrients. This results in the Green Boost Compost Blend product. Some of this product is further processed to create the OrganicHarvest and BioGrow products. In 2023, the output at the split-off point was 500,000 kilograms of GreenBoost. Each kilogram of GreenBoost retails for $6 per kilogram. The joint costs of processing the compost in 2023 was $1,020,000. GFA used 100,000 kilograms of the GreenBoost to create OrganicHarvest, and 50,000 kilograms to create BioGrow. There is a 25% loss of volume when creating the BioGrow product, and a 50% loss of volume when creating OrganicHarvest. The following table outlines the process: Products Volume at split-off (in kilograms) Separable processing costs Volume after additional processing (in kilograms) GreenBoost 350,000 OrganicHarvest 100,000 BioGrow 50,000 $240,000 $100,000 50,000 75,000 Revenue per kilogram $6 $12 $10 David is unsure whether he should continue to produce the three products, or whether it would be more beneficial to focus just on the Green Boost product. Right now, David is tracking profitability using the following format: Revenues-Green Boost ($6 x 350,000 kg) Revenues - OrganicHarvest ($12 50,000 kg) Revenues BioGrow ($10 x 75,000) Total revenues Total costs (joint and separable) Profit $2,100,000 600,000 750,000 3,450,000 (1,360,000) $2,090,000 Page 8 of 11 3176 words Focus + 114%

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts