Question: Given the following data, develop MRP plans for items C, D, E and F. MPS start for end items: The following table shows the MPS

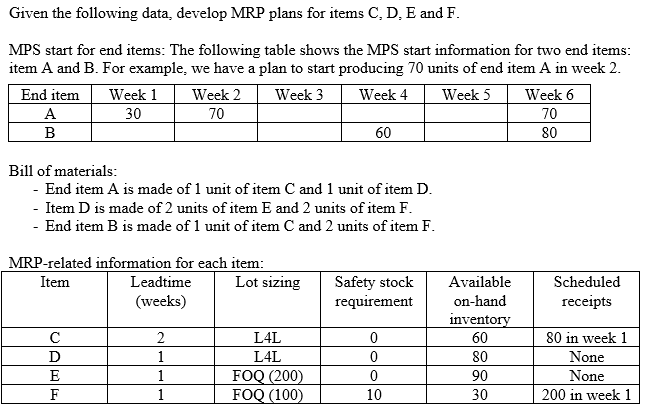

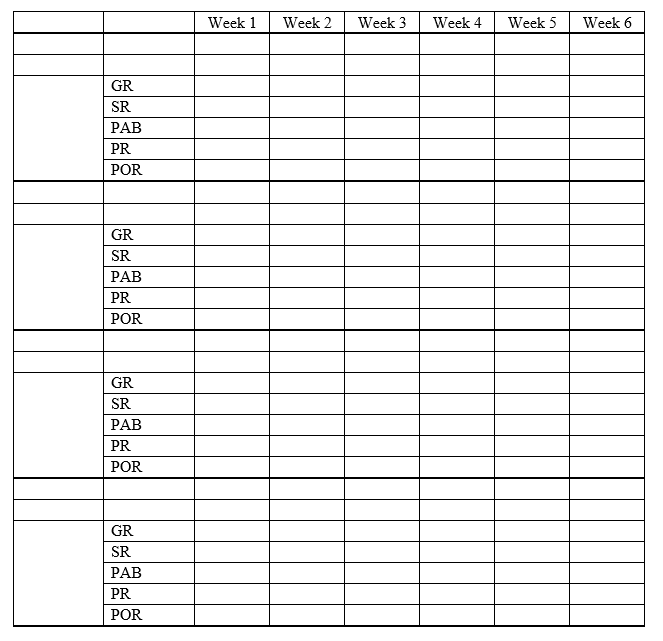

Given the following data, develop MRP plans for items C, D, E and F. MPS start for end items: The following table shows the MPS start information for two end items: item A and B. For example, we have a plan to start producing 70 units of end item A in week 2. End item Week 1 Week 2 Week 3 Week 4 Week 5 Week 6 A 30 70 70 B 60 80 Bill of materials: - End item A is made of 1 unit of item C and 1 unit of item D. - Item D is made of 2 units of item E and 2 units of item F. - End item B is made of 1 unit of item C and 2 units of item F. MRP-related information for each item: Item Leadtime Lot sizing (weeks) Safety stock requirement Scheduled receipts D E F 2 1 1 1 L4L L4L FOQ (200) FOQ (100) 0 0 0 10 Available on-hand inventory 60 80 90 30 80 in week 1 None None 200 in week 1 Week 1 Week 2 Week 3 Week 4 Week 5 Week 6 GR SR PAB PR POR GR SR PAB PR POR GR SR PAB PR POR GR SR PAB PR POR Given the following data, develop MRP plans for items C, D, E and F. MPS start for end items: The following table shows the MPS start information for two end items: item A and B. For example, we have a plan to start producing 70 units of end item A in week 2. End item Week 1 Week 2 Week 3 Week 4 Week 5 Week 6 A 30 70 70 B 60 80 Bill of materials: - End item A is made of 1 unit of item C and 1 unit of item D. - Item D is made of 2 units of item E and 2 units of item F. - End item B is made of 1 unit of item C and 2 units of item F. MRP-related information for each item: Item Leadtime Lot sizing (weeks) Safety stock requirement Scheduled receipts D E F 2 1 1 1 L4L L4L FOQ (200) FOQ (100) 0 0 0 10 Available on-hand inventory 60 80 90 30 80 in week 1 None None 200 in week 1 Week 1 Week 2 Week 3 Week 4 Week 5 Week 6 GR SR PAB PR POR GR SR PAB PR POR GR SR PAB PR POR GR SR PAB PR POR

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts