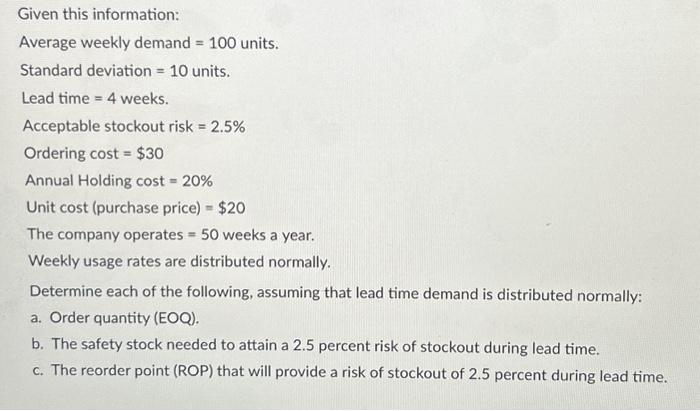

Question: Given this information: Average weekly demand =100 units. Standard deviation =10 units. Lead time =4 weeks. Acceptable stockout risk =2.5% Ordering cost =$30 Annual Holding

Given this information: Average weekly demand =100 units. Standard deviation =10 units. Lead time =4 weeks. Acceptable stockout risk =2.5% Ordering cost =$30 Annual Holding cost =20% Unit cost (purchase price) =$20 The company operates =50 weeks a year. Weekly usage rates are distributed normally. Determine each of the following, assuming that lead time demand is distributed normally: a. Order quantity (EOQ). b. The safety stock needed to attain a 2.5 percent risk of stockout during lead time. c. The reorder point (ROP) that will provide a risk of stockout of 2.5 percent during lead time

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts