Question: Go over problems 2 and 3, which are already solved . You need to understand computation logic, methods and calculations. Discuss when the Q system

Go over problems 2 and 3, which are already solved. You need to understand computation logic, methods and calculations.

Discuss when the Q system is used and when the P system is used.

Question What are the distinguishing criteria for when they are used?

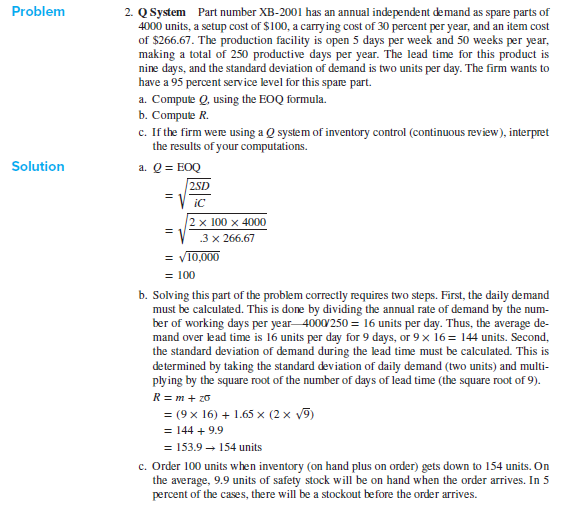

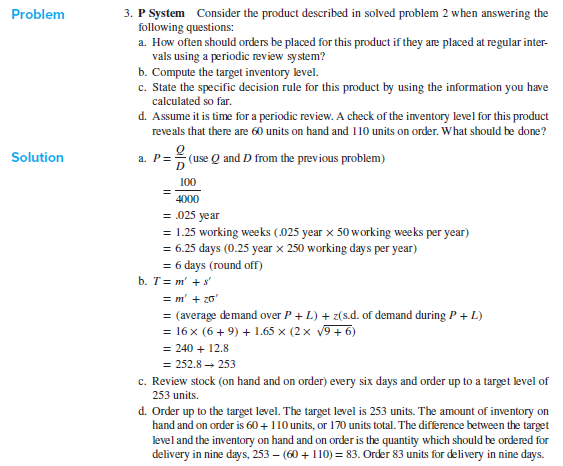

Problem 2. Q System Part number XB-2001 has an annual independent demand as spare parts of 4000 units, a setup cost of $100, a carrying cost of 30 percent per year, and an item cost of $266.67. The production facility is open 5 days per week and 50 weeks per year, making a total of 250 productive days per year. The lead time for this product is nine days, and the standard deviation of demand is two units per day. The firm wants to have a 95 percent service level for this spare part. a. Compute , using the EOQ formula. b. Compute R. c. If the firm were using a Q system of inventory control (continuous review), interpret the results of your computations. a. Q = EOQ 2SD Solution - Vic 2 x 100 x 4000 .3 x 266.67 = V10,000 = 100 b. Solving this part of the problem correctly requires two steps. First, the daily demand must be calculated. This is done by dividing the annual rate of demand by the num- ber of working days per year4000/250 = 16 units per day. Thus, the average de- mand over lead time is 16 units per day for 9 days, or 9 x 16 = 144 units. Second, the standard deviation of demand during the lead time must be calculated. This is determined by taking the standard deviation of daily demand (two units) and multi- plying by the square root of the number of days of lead time (the square root of 9). R=m+ zo = (9 x 16) + 1.65 X (2 x V9) = 144 +9.9 = 153.9 154 units c. Order 100 units when inventory (on hand plus on order) gets down to 154 units. On the average, 9.9 units of safety stock will be on hand when the order arrives. In 5 percent of the cases, there will be a stockout before the order arrives. Problem Solution 3. P System Consider the product described in solved problem 2 when answering the following questions: a. How often should orders be placed for this product if they are placed at regular inter- vals using a periodic review system? b. Compute the target inventory level. C. State the specific decision rule for this product by using the information you have calculated so far. d. Assume it is time for a periodic review. A check of the inventory level for this product reveals that there are 60 units on hand and 110 units on order. What should be done? Q a. P= (use Q and D from the previous problem) 100 4000 = .025 year = 1.25 working weeks (.025 year x 50 working weeks per year) = 6.25 days (0.25 year x 250 working days per year) = 6 days (round off) b. T= m' + s' = m' + zo = (average demand over P+L) + z(s.d. of demand during P+L) = 16 X (6 +9) + 1.65 x (2 x V9+6) = 240 + 12.8 = 252.8 253 c. Review stock (on hand and on order) every six days and order up to a target level of 253 units. d. Order up to the target level. The target level is 253 units. The amount of inventory on hand and on order is 60+ 110 units, or 170 units total. The difference between the target level and the inventory on hand and on order is the quantity which should be ordered for delivery in nine days, 253 (60 + 110) = 83. Order 83 units for delivery in nine days

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts