Question: please help. These problem are alredy solved but i do not understand them, could someone help me understand computation logic and solution. thank you in

please help. These problem are alredy solved but i do not understand them, could someone help me understand computation logic and solution. thank you in advance.

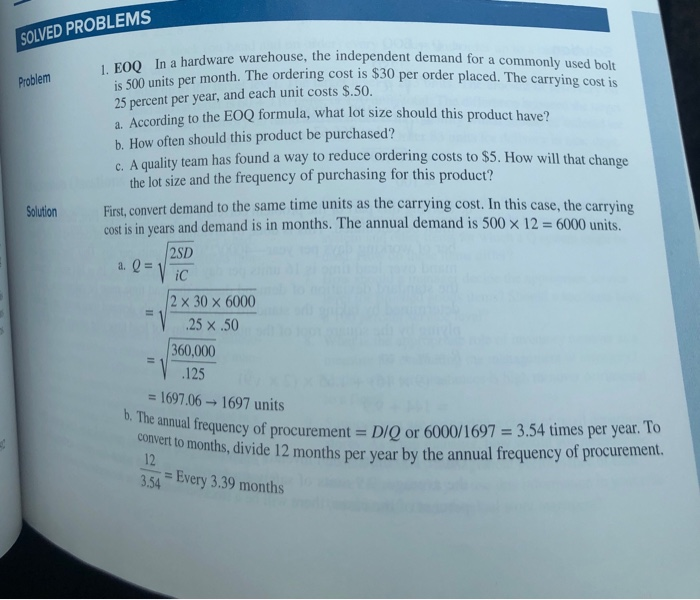

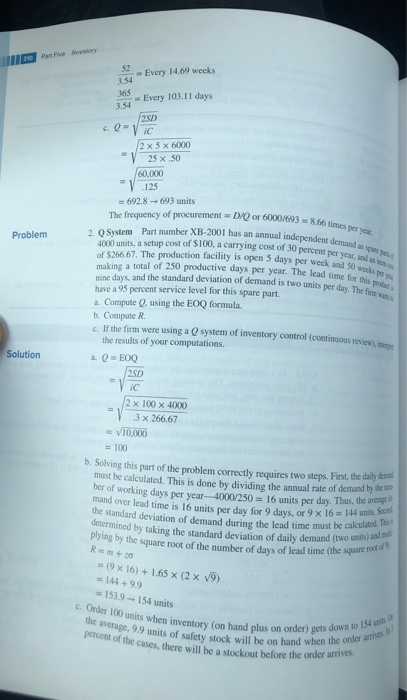

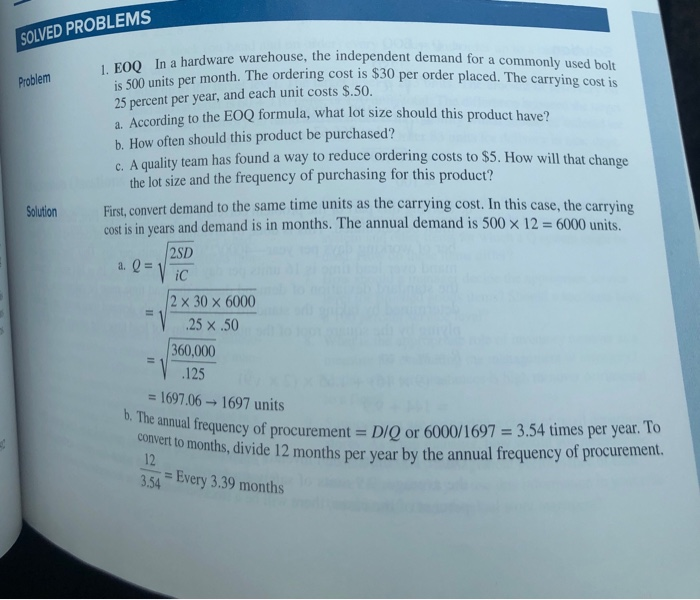

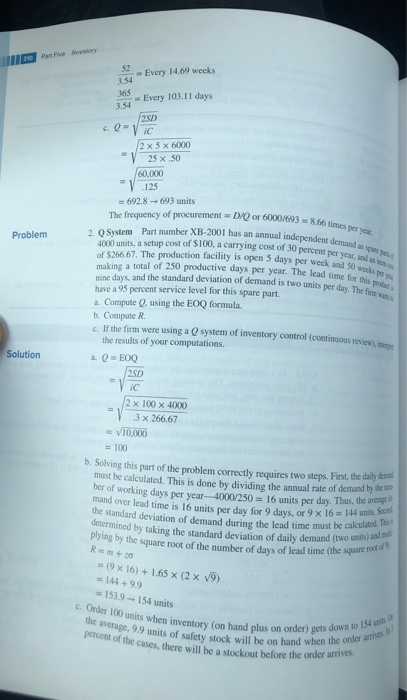

SOLVED PROBLEMS 1. EOQ In a hardware warehouse, the Problem rdware warehouse, the independent demand for a commonly used bolt rdering cost is $30 per order placed. The carrying cost is 500 units per month. The ordering cost is $30 per order placed the 25 percent per year, and each unit costs $.50. According to the EOQ formula, what lot size should this product have? b. How often should this product be purchased? team has found a way to reduce ordering costs to $5. How will that change the lot size and the frequency of purchasing for this product? First convert demand to the same time units as the carrying cost. In this case, the carrying cost is in years and demand is in months. The annual demand is 500 x 12 = 6000 units. Solution 2SD a. e=Vic 2 x 30 x 6000 .25 .50 360,000 125 = 1697.06 1697 units annual frequency of procurement = D/O or 6000/1697 = 3.54 times per year. To divide 12 months per year by the annual frequency of procurement. 12 3.54 = Every 3.39 months convert to months, divide 12 months per year 32 Every 14.69 weeks 3 365 Every 103.11 days 3.54 2SD ceyic 2 x 5 x 6000 "V 25 x 50 160,000 * 1.125 = 692.8 - 693 units The frequency of procurement = DQ or 6000/693 O Sustem Part number XB-2001 has an annual independent de is a setup cost of S100, a carrying cost of 30 percent $266 67. The production facility is open days per week and making a total of 250 productive days per year. The lead time for nine days and the standard deviation of demand is two units per have a 95 percent service level for this spare part a Compute, using the EOQ formula b. Compute R. If the firm were using a system of inventory control continuous review, the results of your computations O ECO 8.66 times per you et demand as su Problem 50 words per day. The fimm Solution 250 ic 2 x 100 x 4000 Y3 x 266.67 = V10,000 = 100 b. Solving this part of the problem correctly requires two steps. First, the daily dom must be calculated. This is done by dividing the annual rate of demands ber of working days per year-4000/250 = 16 units per day. Thus, the mand over lead time is 16 units per day for 9 days, or 9 x 16 = 14 the standard deviation of demand during the lead time must be calcu. by taking the standard deviation of daily demand (wo twn uits) and ) plying by the square root of the number of days of lead time (the determined by taking the standard deviatu days, or 9 x 16 = 144 units. Som the lead time must be calculated. This Time (the square not Ram+30 = 19 x 16) + 1.65 X (2 x 19) = 144 +99 = 1539-154 units e. Order 100 units when inventory the average, 99 units of safety percent of the cases, there will be a Percent ,99 uden inventory en inventory (on hand plus on order) gets down to 9 units of safety stock will be on hand when the one cases, there will be a stockout before the order arrives wn to 1540 order ammes