Question: Harley - Davidson has its engine assembly plant in Milwaukee and its motorcycle assembly plant in Pennsylvania. Engines are transported between the two plants using

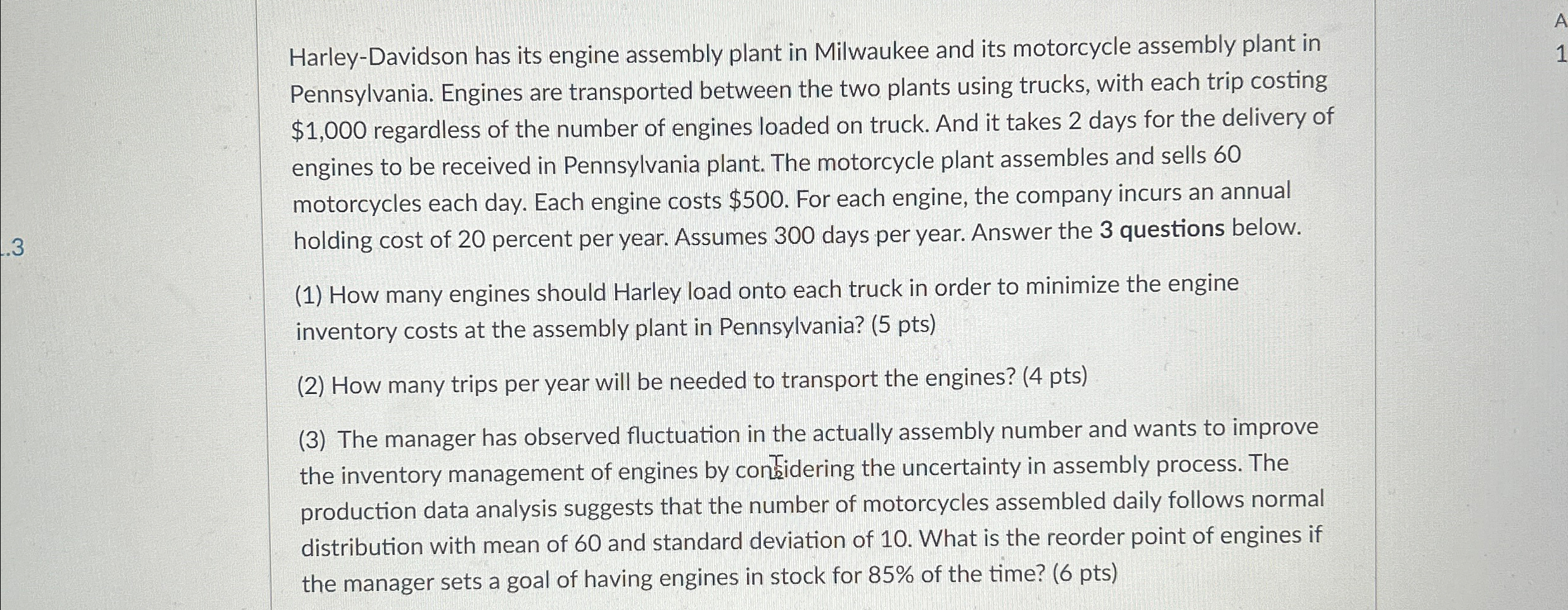

HarleyDavidson has its engine assembly plant in Milwaukee and its motorcycle assembly plant in Pennsylvania. Engines are transported between the two plants using trucks, with each trip costing $ regardless of the number of engines loaded on truck. And it takes days for the delivery of engines to be received in Pennsylvania plant. The motorcycle plant assembles and sells motorcycles each day. Each engine costs $ For each engine, the company incurs an annual holding cost of percent per year. Assumes days per year. Answer the questions below.

How many engines should Harley load onto each truck in order to minimize the engine inventory costs at the assembly plant in Pennsylvania? pts

How many trips per year will be needed to transport the engines? pts

The manager has observed fluctuation in the actually assembly number and wants to improve the inventory management of engines by con Lidering the uncertainty in assembly process. The production data analysis suggests that the number of motorcycles assembled daily follows normal distribution with mean of and standard deviation of What is the reorder point of engines if the manager sets a goal of having engines in stock for of the time? pts

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock