Question: Hello dear Please answer this question Note I need u to answer my questions by using my values Look carefully to annual quantity values With

Hello dear

Please answer this question

Note

I need u to answer my questions by using my values

Look carefully to annual quantity values

With best regards

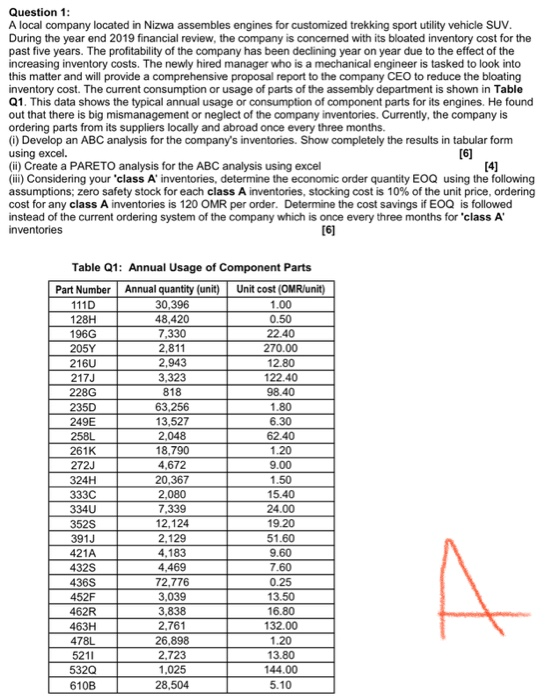

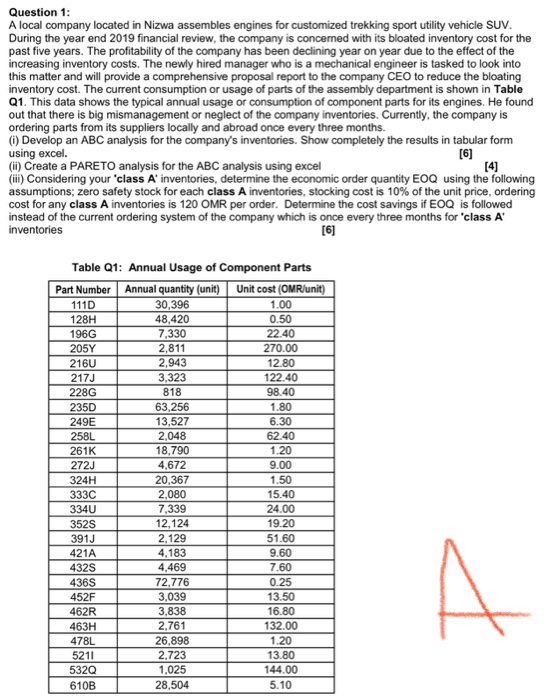

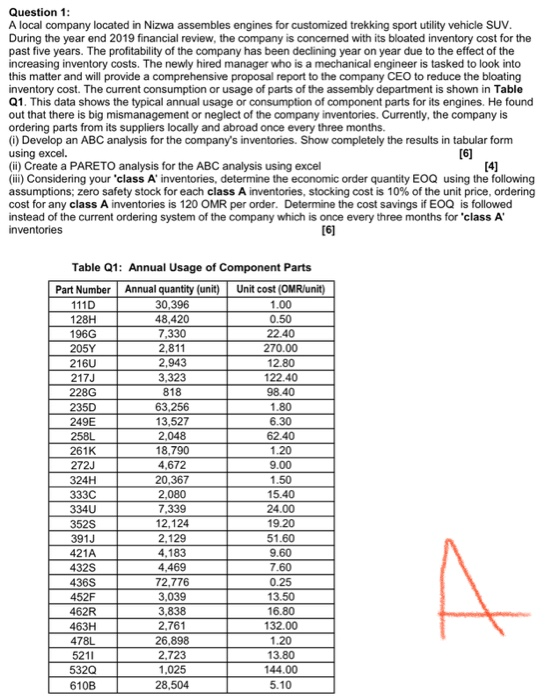

Question 1: A local company located in Nizwa assembles engines for customized trekking sport utility vehicle SUV. During the year end 2019 financial review, the company is concerned with its bloated inventory cost for the past five years. The profitability of the company has been declining year on year due to the effect of the increasing inventory costs. The newly hired manager who is a mechanical engineer is tasked to look into this matter and will provide a comprehensive proposal report to the company CEO to reduce the bloating inventory cost. The current consumption or usage of parts of the assembly department is shown in Table Q1. This data shows the typical annual usage or consumption of component parts for its engines. He found out that there is big mismanagement or neglect of the company inventories. Currently, the company is ordering parts from its suppliers locally and abroad once every three months. (0) Develop an ABC analysis for the company's inventories. Show completely the results in tabular form using excel. (6) Create a PARETO analysis for the ABC analysis using excel (1) Considering your class A inventories, determine the economic order quantity EOQ using the following assumptions; zero safety stock for each class A inventories, stocking cost is 10% of the unit price, ordering cost for any class A inventories is 120 OMR per order. Determine the cost savings if EOQ is followed instead of the current ordering system of the company which is once every three months for class A inventories Table Q1: Annual Usage of Component Parts Part Number Annual quantity (unit) Unit cost (OMR/unit) 111D 30,396 1.00 128H 48,420 0.50 196G 7,330 22.40 205Y 2,811 270.00 216U 2.943 12.80 217J 3,323 122.40 228G 818 98.40 235D 63,256 1.80 249E 13,527 6.30 258L 2,048 62.40 261K 18.790 1.20 272J 4,672 9.00 324H 20,367 1.50 333C 2,080 15.40 334U 7,339 24.00 3525 12,124 19.20 391J 2.129 51.60 421A 4,183 9.60 432S 4,469 7.60 4365 72,776 0.25 452F 3,039 13.50 462R 3.838 16.80 463H 2,761 132.00 478L 26.898 1.20 5211 2.723 13.80 5320 1,025 144.00 610B 28,504 5.10 A Question 1: A local company located in Nizwa assembles engines for customized trekking sport utility vehicle SUV. During the year end 2019 financial review, the company is concerned with its bloated inventory cost for the past five years. The profitability of the company has been declining year on year due to the effect of the increasing inventory costs. The newly hired manager who is a mechanical engineer is tasked to look into this matter and will provide a comprehensive proposal report to the company CEO to reduce the bloating inventory cost. The current consumption or usage of parts of the assembly department is shown in Table Q1. This data shows the typical annual usage or consumption of component parts for its engines. He found out that there is big mismanagement or neglect of the company inventories. Currently, the company is ordering parts from its suppliers locally and abroad once every three months. (0) Develop an ABC analysis for the company's inventories. Show completely the results in tabular form using excel. (6) Create a PARETO analysis for the ABC analysis using excel (1) Considering your class A inventories, determine the economic order quantity EOQ using the following assumptions; zero safety stock for each class A inventories, stocking cost is 10% of the unit price, ordering cost for any class A inventories is 120 OMR per order. Determine the cost savings if EOQ is followed instead of the current ordering system of the company which is once every three months for class A inventories Table Q1: Annual Usage of Component Parts Part Number Annual quantity (unit) Unit cost (OMR/unit) 111D 30,396 1.00 128H 48,420 0.50 196G 7,330 22.40 205Y 2,811 270.00 216U 2.943 12.80 217J 3,323 122.40 228G 818 98.40 235D 63,256 1.80 249E 13,527 6.30 258L 2,048 62.40 261K 18.790 1.20 272J 4,672 9.00 324H 20,367 1.50 333C 2,080 15.40 334U 7,339 24.00 3525 12,124 19.20 391J 2.129 51.60 421A 4,183 9.60 432S 4,469 7.60 4365 72,776 0.25 452F 3,039 13.50 462R 3.838 16.80 463H 2,761 132.00 478L 26.898 1.20 5211 2.723 13.80 5320 1,025 144.00 610B 28,504 5.10 A