Question: Help 4.42 A process flowehat and a wemestat everinphified dessriprion of what huppens in the proces follow: Problems 189 Inside the column a liquid stream

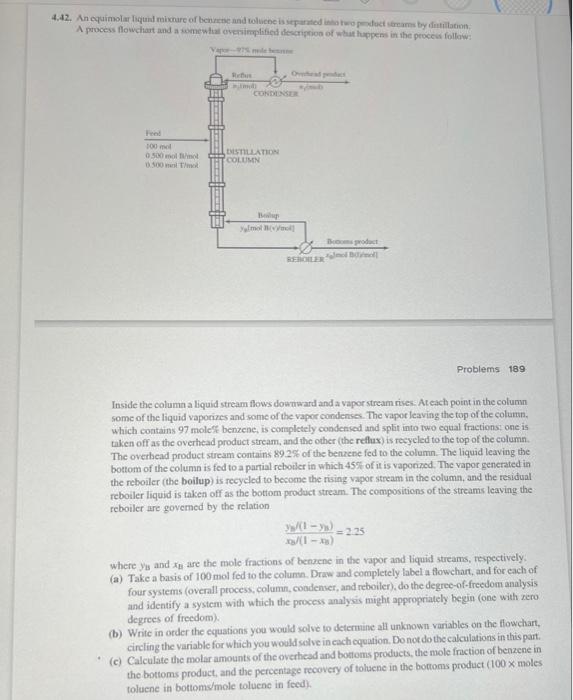

A process flowehat and a wemestat everinphified dessriprion of what huppens in the proces follow: Problems 189 Inside the column a liquid stream flows downward and a vapor stream rives. At each point in the column some of the liquid vaporires and some of the vapor condenses. The vapor leaving the top of the column. which contains 97 molef benzene, is completely condenved and split into two equal fractions: one is taken off as the overhead product stream, and the other (the reflax) is reeycled to the top of the column. The overbead product siream contains 892% of the berzene fed to the column. The liquid leaving the bottom of the colunn is fed to a partial rebotler in which 45% of it is vaporized. The vapor generated in the reboiler (the boilup) is recycled to besome the rising vapor stream in the column, and the residual reboiler liquid is taken off as the bottom product stream. The compositions of the streams leaving the reboiler are govemed by the relation x3/(1x3)y2/(1y1)=2.25 where y3 and x1 are the mole fractions of benzene in the vapor and liquid streams, respectively. (a) Take a basis of 100mol fed to the colume. Draw and completely label a flowehart, and for each of four systems (overall process, column, condenier, and reboiler), do the degree-of-freedom analysis and identify a system with which the process analysis might appropriately beein (one with rero degrees of freedom). (b) Write in order the equations you would solve to determine all unknown varables on the flowehart, circling the variable for whch you would selve in each cquation. Donot do the calculations in this pant. (c) Calculate the molar amounts of the overhesd and botioms products, the mole fruction of benzene in the botioms product, and the pereentage recovery of toluene in the botoms product (100 moles toluene in bottomsmole toluene in feed). A process flowehat and a wemestat everinphified dessriprion of what huppens in the proces follow: Problems 189 Inside the column a liquid stream flows downward and a vapor stream rives. At each point in the column some of the liquid vaporires and some of the vapor condenses. The vapor leaving the top of the column. which contains 97 molef benzene, is completely condenved and split into two equal fractions: one is taken off as the overhead product stream, and the other (the reflax) is reeycled to the top of the column. The overbead product siream contains 892% of the berzene fed to the column. The liquid leaving the bottom of the colunn is fed to a partial rebotler in which 45% of it is vaporized. The vapor generated in the reboiler (the boilup) is recycled to besome the rising vapor stream in the column, and the residual reboiler liquid is taken off as the bottom product stream. The compositions of the streams leaving the reboiler are govemed by the relation x3/(1x3)y2/(1y1)=2.25 where y3 and x1 are the mole fractions of benzene in the vapor and liquid streams, respectively. (a) Take a basis of 100mol fed to the colume. Draw and completely label a flowehart, and for each of four systems (overall process, column, condenier, and reboiler), do the degree-of-freedom analysis and identify a system with which the process analysis might appropriately beein (one with rero degrees of freedom). (b) Write in order the equations you would solve to determine all unknown varables on the flowehart, circling the variable for whch you would selve in each cquation. Donot do the calculations in this pant. (c) Calculate the molar amounts of the overhesd and botioms products, the mole fruction of benzene in the botioms product, and the pereentage recovery of toluene in the botoms product (100 moles toluene in bottomsmole toluene in feed)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts