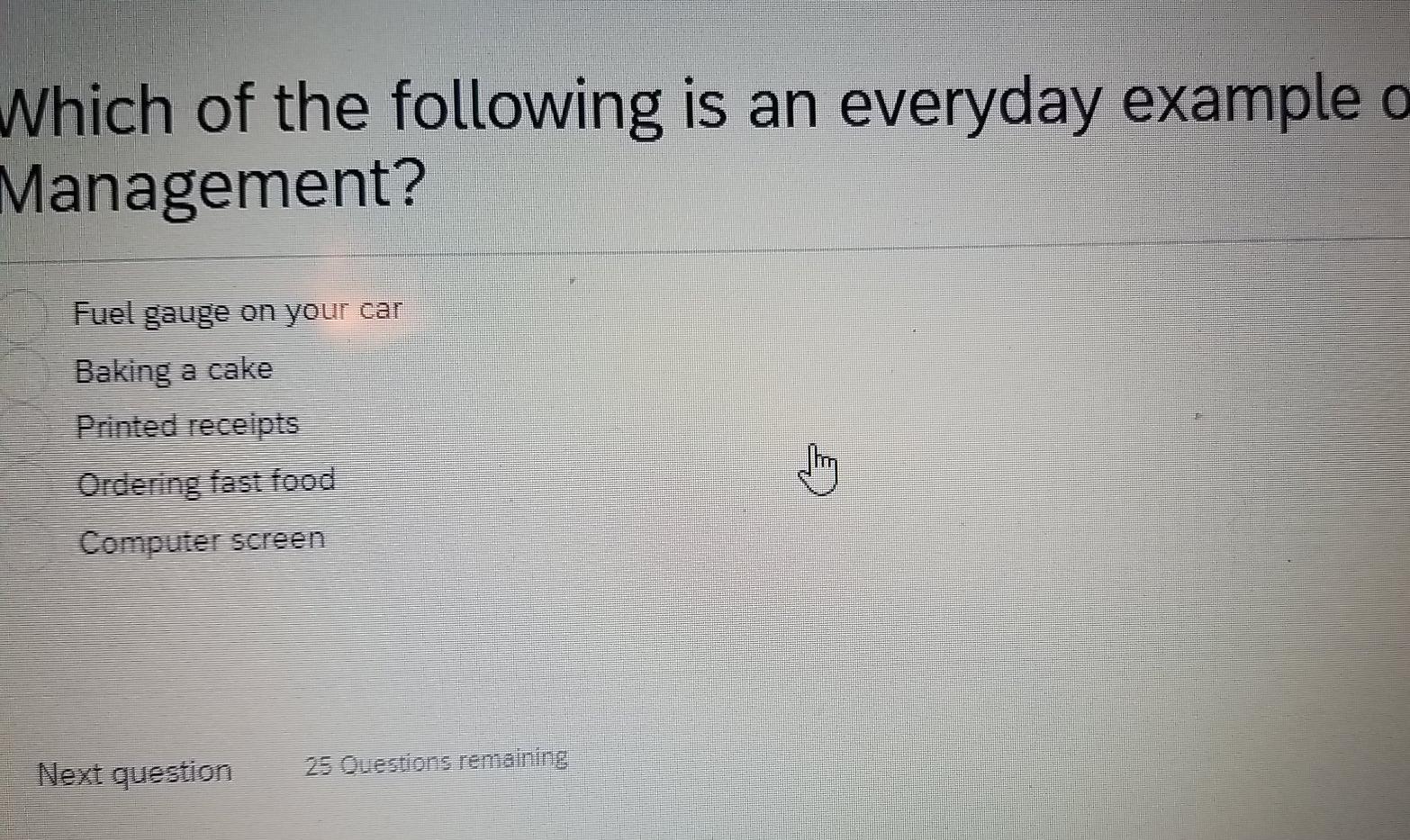

Question: help done it over 20 times and fail miserably Which of the following is an everyday example o Management? Fuel gauge on your car Baking

help done it over 20 times and fail miserably

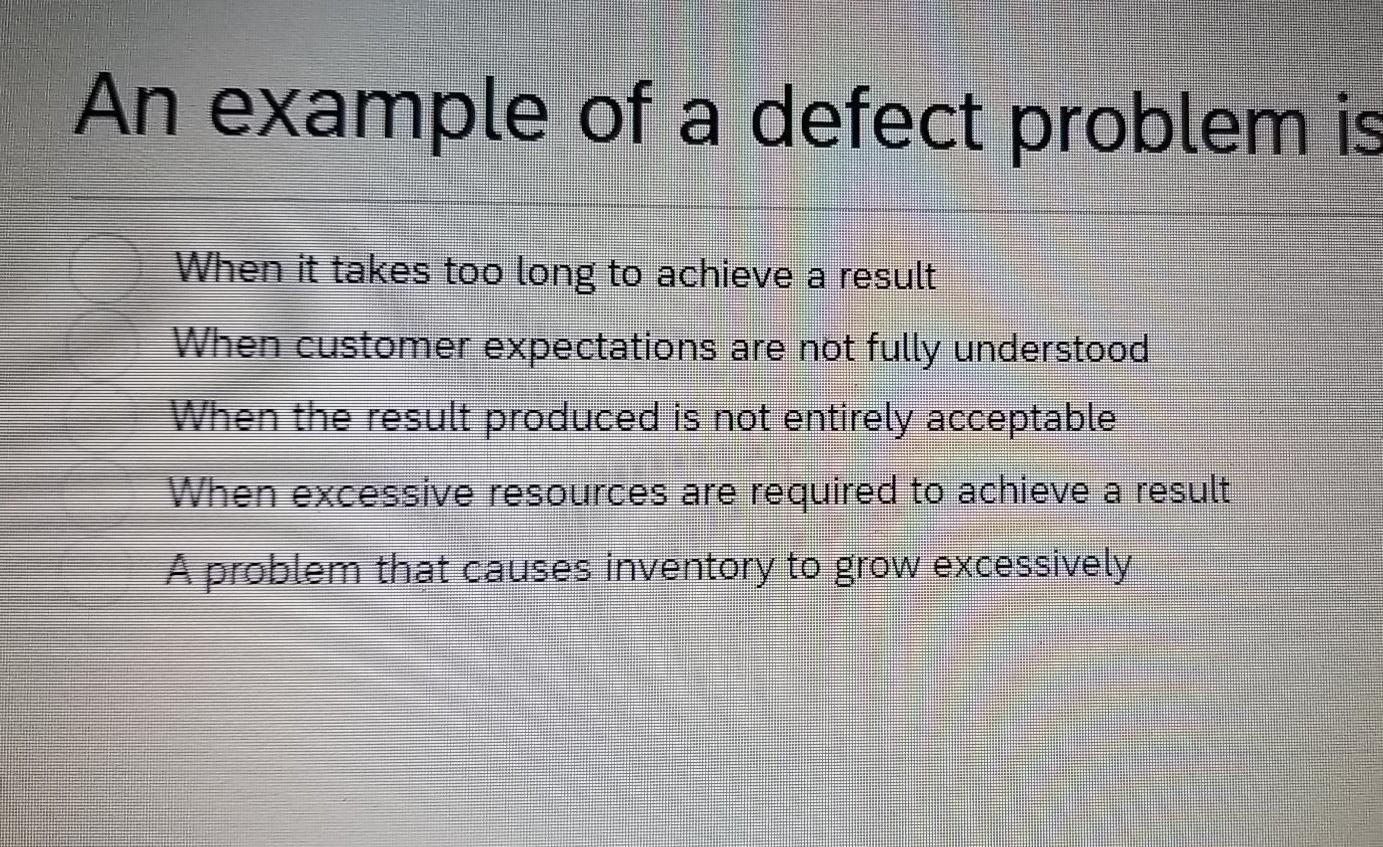

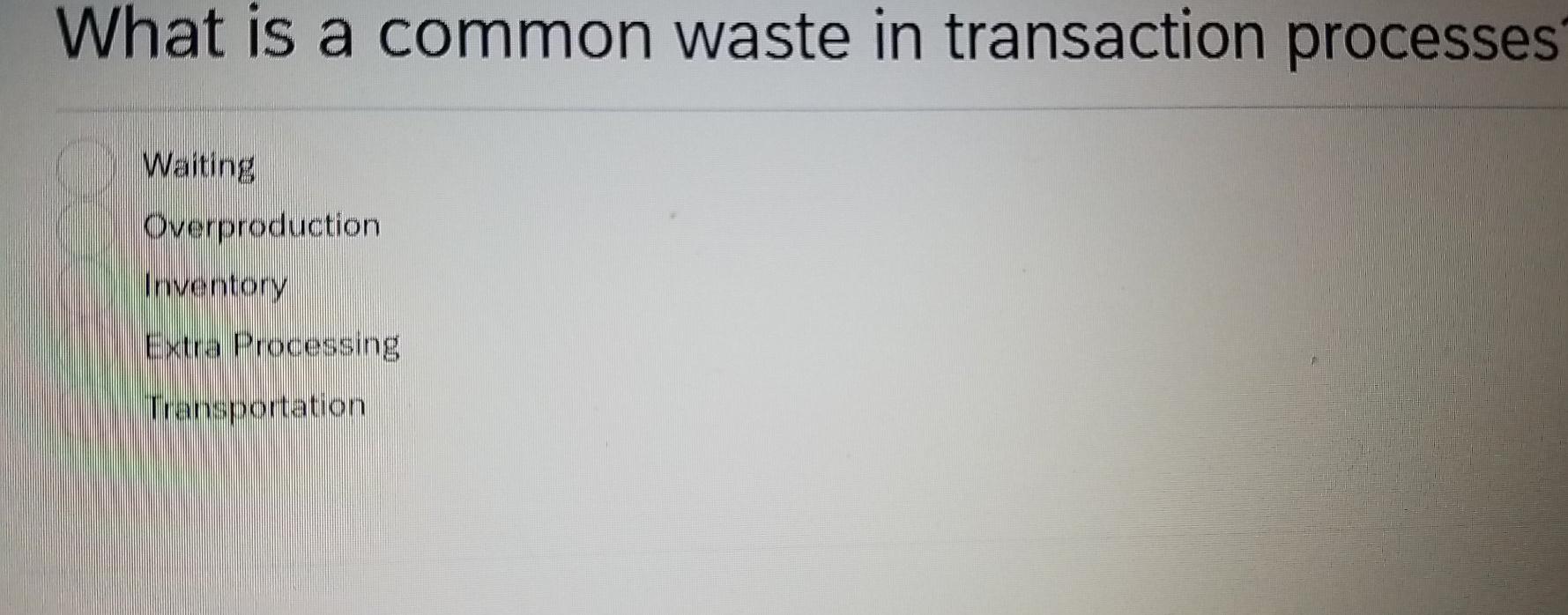

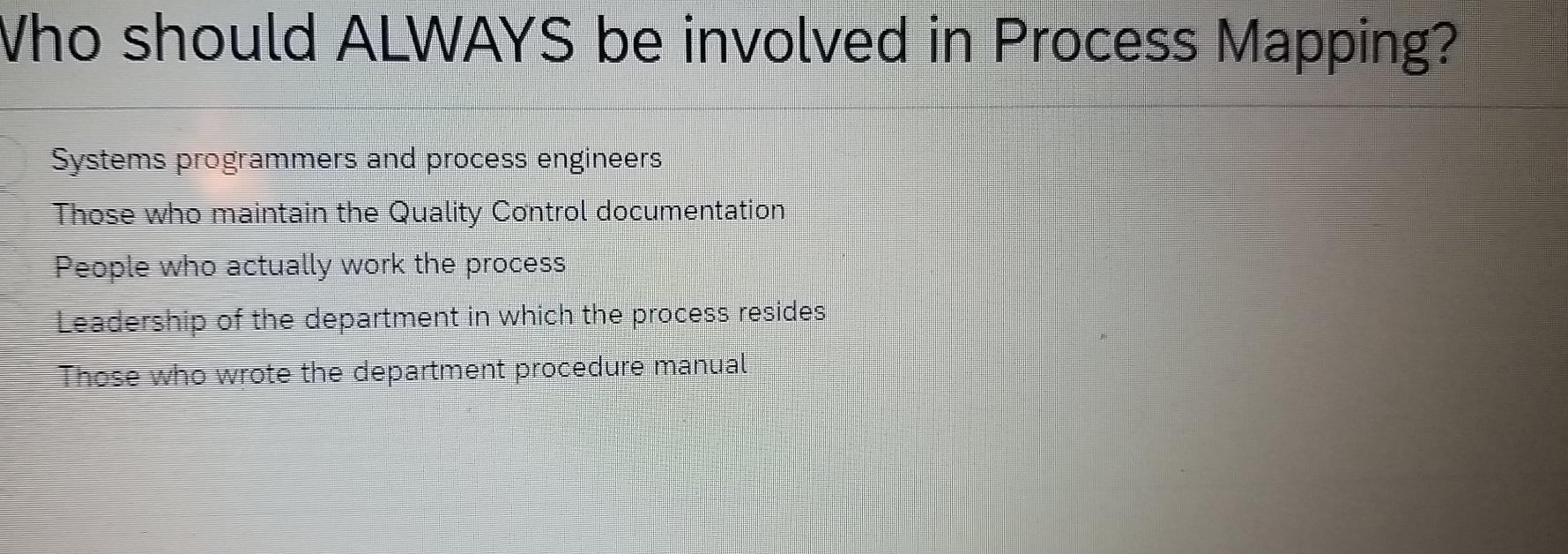

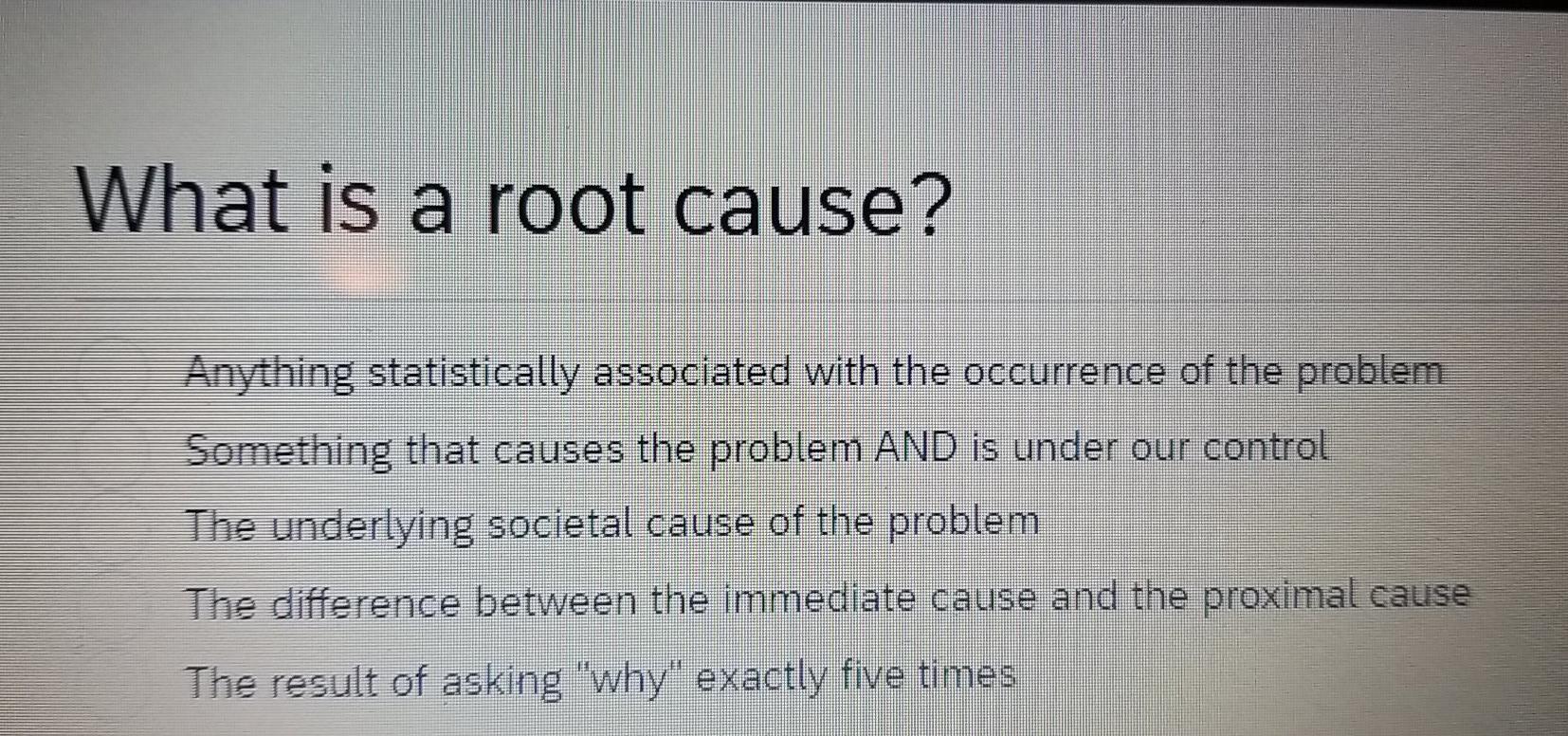

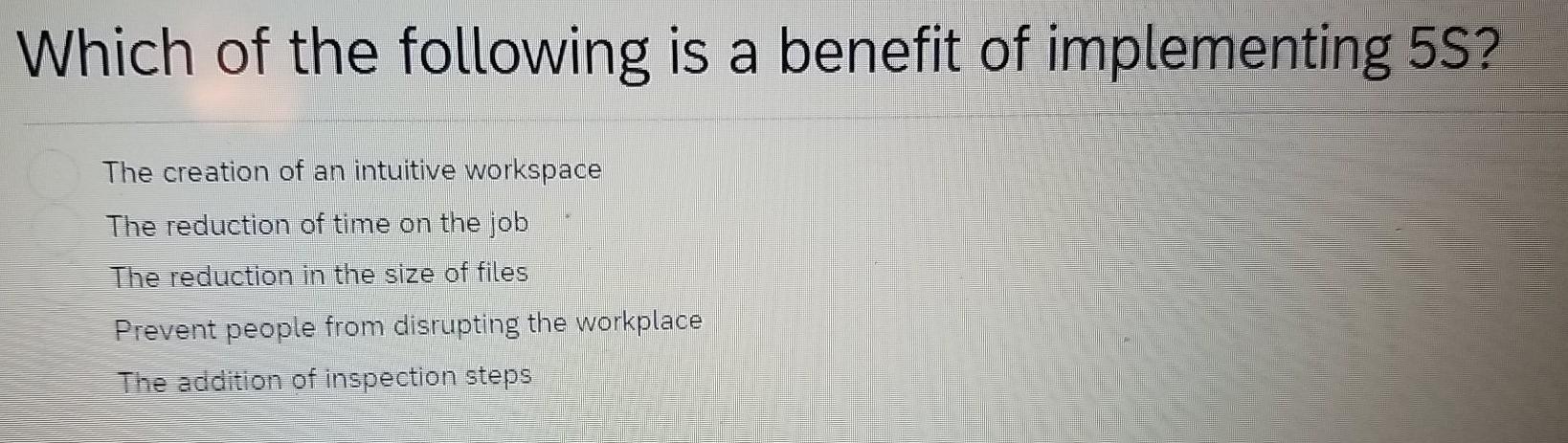

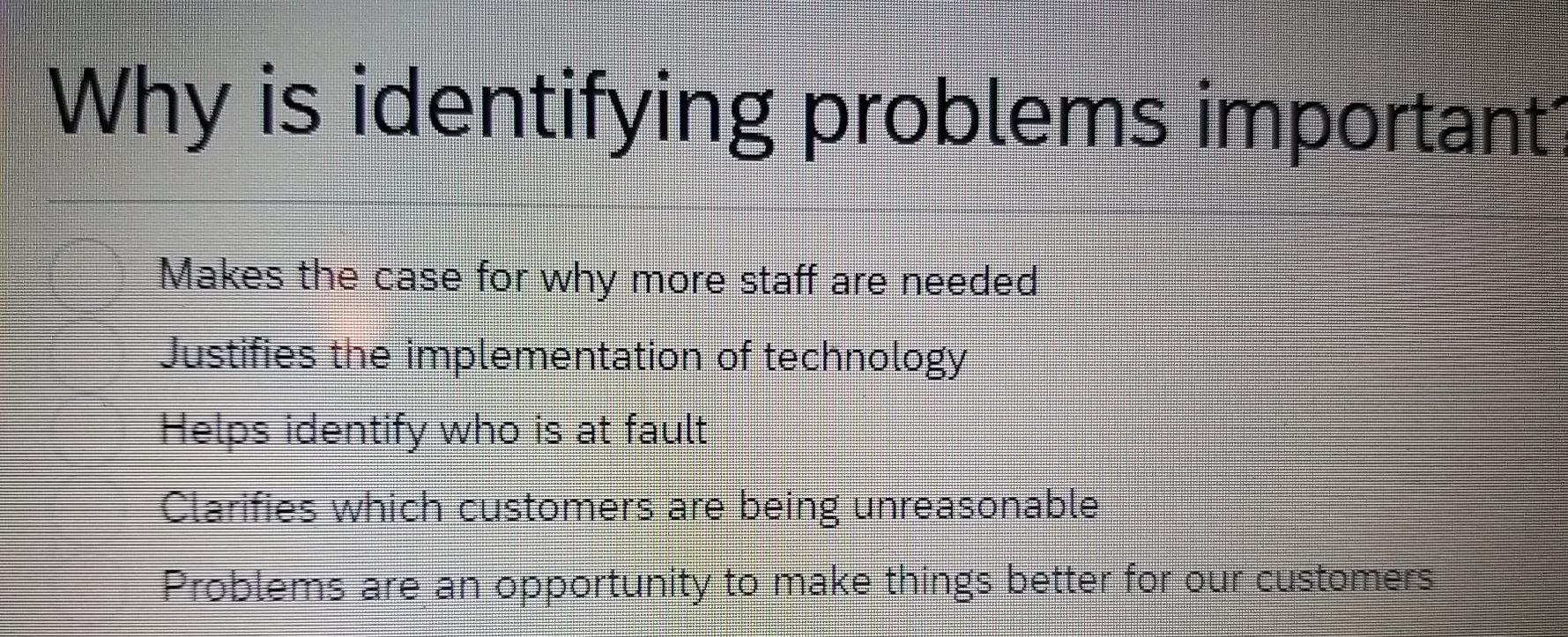

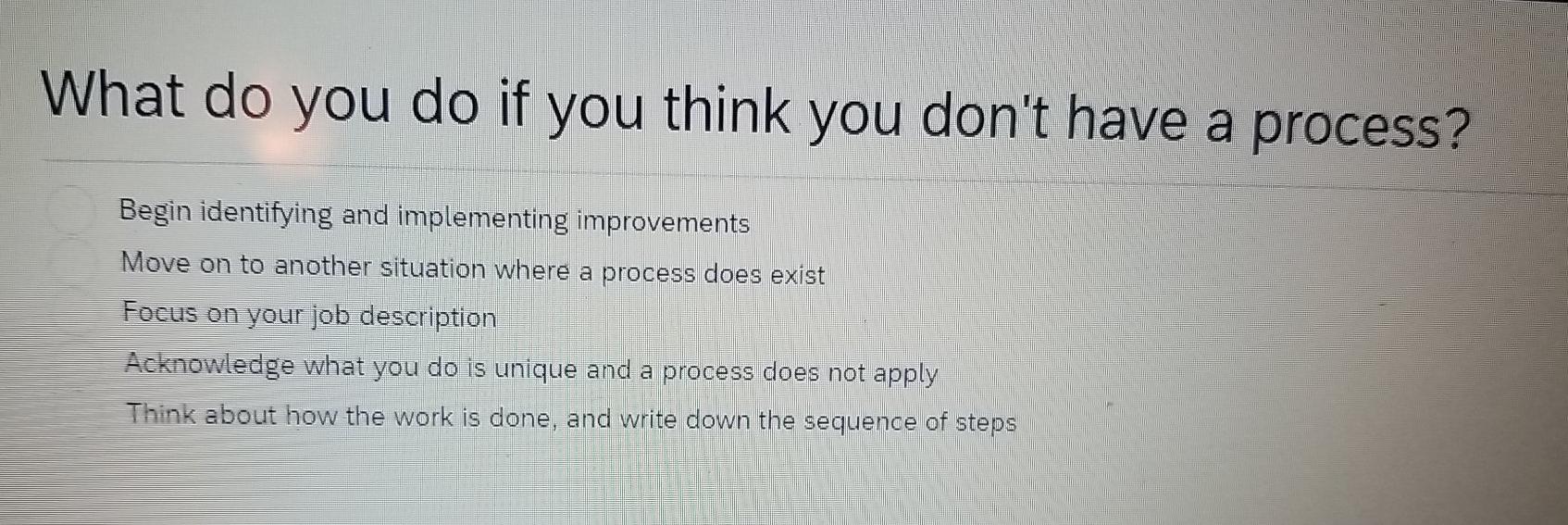

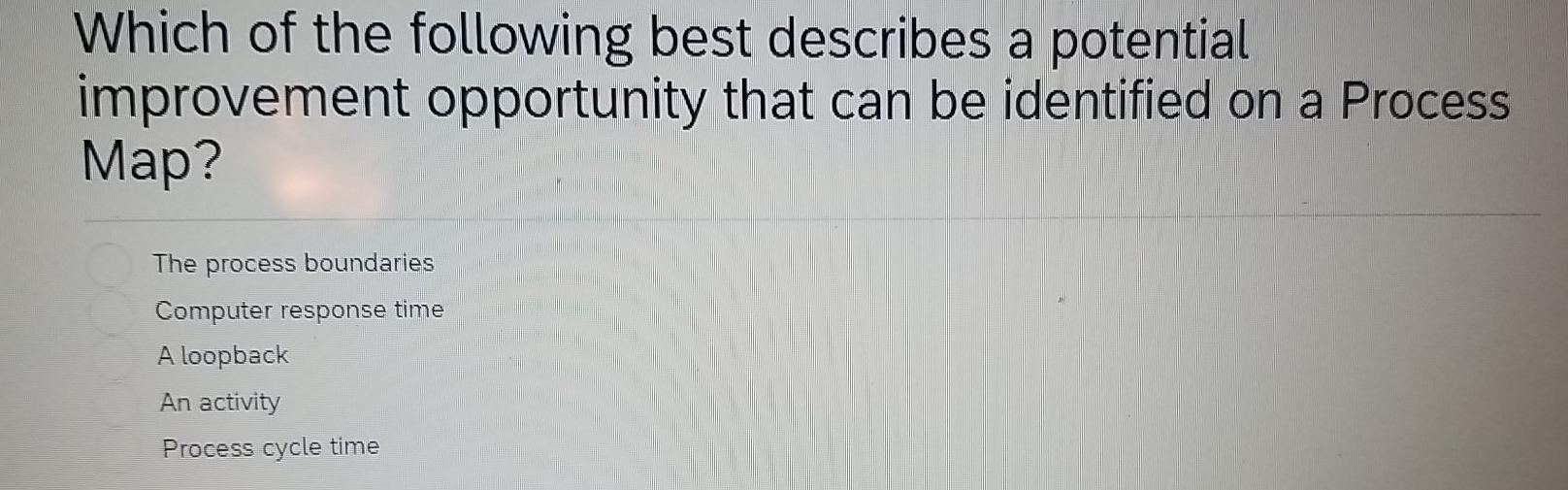

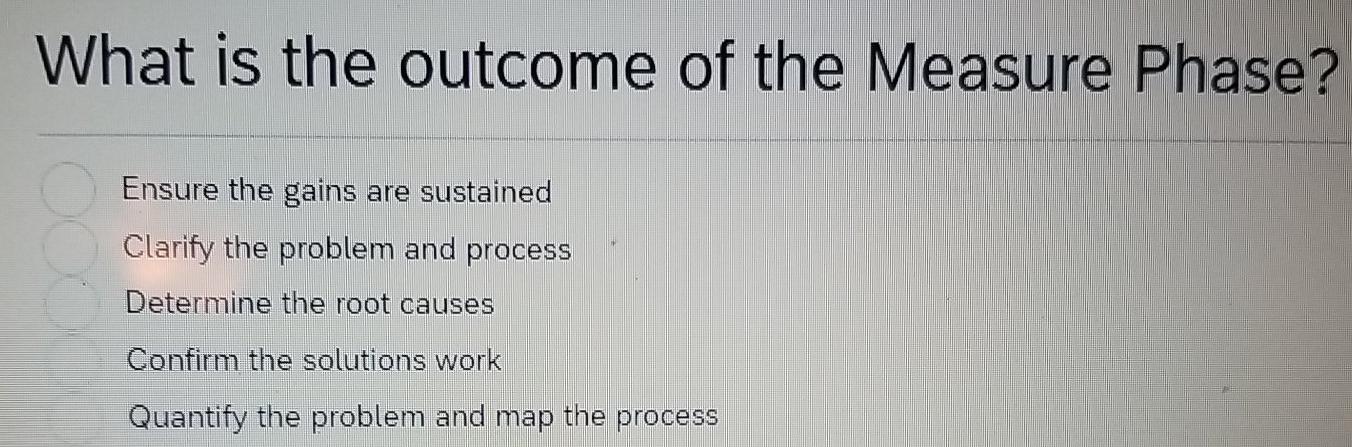

Which of the following is an everyday example o Management? Fuel gauge on your car Baking a cake Printed receipts Ordering fast food Computer screen Next question 25 Questions remaining An example of a defect problem is When it takes too long to achieve a result When customer expectations are not fully understood When the result produced is not entirely acceptable When excessive resources are required to achieve a result A problem that causes inventory to grow excessively Vho should ALWAYS be involved in Process Mapping? Systems programmers and process engineers Those who maintain the Quality Control documentation People who actually work the process Leadership of the department in which the process resides Those who wrote the department procedure manual When do you stop asking "why?" After exactly 5 whys When team consensus is achieved Any time before 5 whys are asked When no further whys can be answered When you reach a dead end What criteria should be used when to decide to act on waste? It is moved to the red tag area It represents two or more of the 8 wastes It can be eliminated without making a capital purchase It doesn't look nice It has a significant impact on the operation or outcome of the process or contributes to the problem at hand When do you stop asking "why?" When you've reached the root cause When you've identified the person responsible When the team agrees When you've identified the best solution After exactly 5 whys A cycle time problem can lead to Increased productivity A reduction in staff hours Work being completed early No: being able to produce enough in the time available Defects or inaccuracies What should be done if it is difficult to determine which of the 8 Wastes to assign? Conduct a multi-vote by your team Ask the process participant nearest the waste The name is the same as the most similar waste found Choose a waste not yet selected, or less often selected Just pick one because seeing the waste is more important than naming it Vhat is the purpose of the STANDARDIZE step? To establish standard cost values for the work To define periodic clean-up duties for each person To define the standard work for each process step To challenge the workforce to reach higher levels of performance To assure that only proper materials are used in the process hat should participants look for in a Process Walk? Opportunities for headcount reduction The degree of cooperation between process participants Process participants not executing their functions properly Weste flow disruptions and deviations from the process map Solutions that can be readily implemented What is the outcome of the Improve Phase? Confirm the solutions work Determine the root causes Clarify the problem and process Quantify the problem and map the process Ensure the gains are sustained What is a root cause? Anything statistically associated with the occurrence of the problem Something that causes the problem AND is under our control The underlying societal cause of the problem The difference between the immediate cause and the proximal cause The result of asking "why" exactly five times Which of the following is a benefit of implementing 5S? The creation of an intuitive workspace The reduction of time on the job The reduction in the size of files Prevent people from disrupting the workplace The addition of inspection steps Why is identifying problems important Makes the case for why more staff are needed Justifies the implementation of technology Helps identify who is at fault Clarifies which customers are being unreasonable Problems are an opportunity to make things better for our customers What do you do if you think you don't have a process? Begin identifying and implementing improvements Move on to another situation where a process does exist Focus on your job description Acknowledge what you do is unique and a process does not apply Think about how the work is done, and write down the sequence of steps Which of the following best describes a potential improvement opportunity that can be identified on a Process ? The process boundaries Computer response time A loopback An activity Process cycle time What is the outcome of the Measure Phase? Ensure the gains are sustained Clarify the problem and process Determine the root causes Confirm the solutions work Quantify the problem and map the processStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock