Question: Help me develop and understand a value stream map for the data below. Customer Requirements Your customer, Modern Estates, Ltd., requires a total of 18,000

Help me develop and understand a value stream map for the data below.

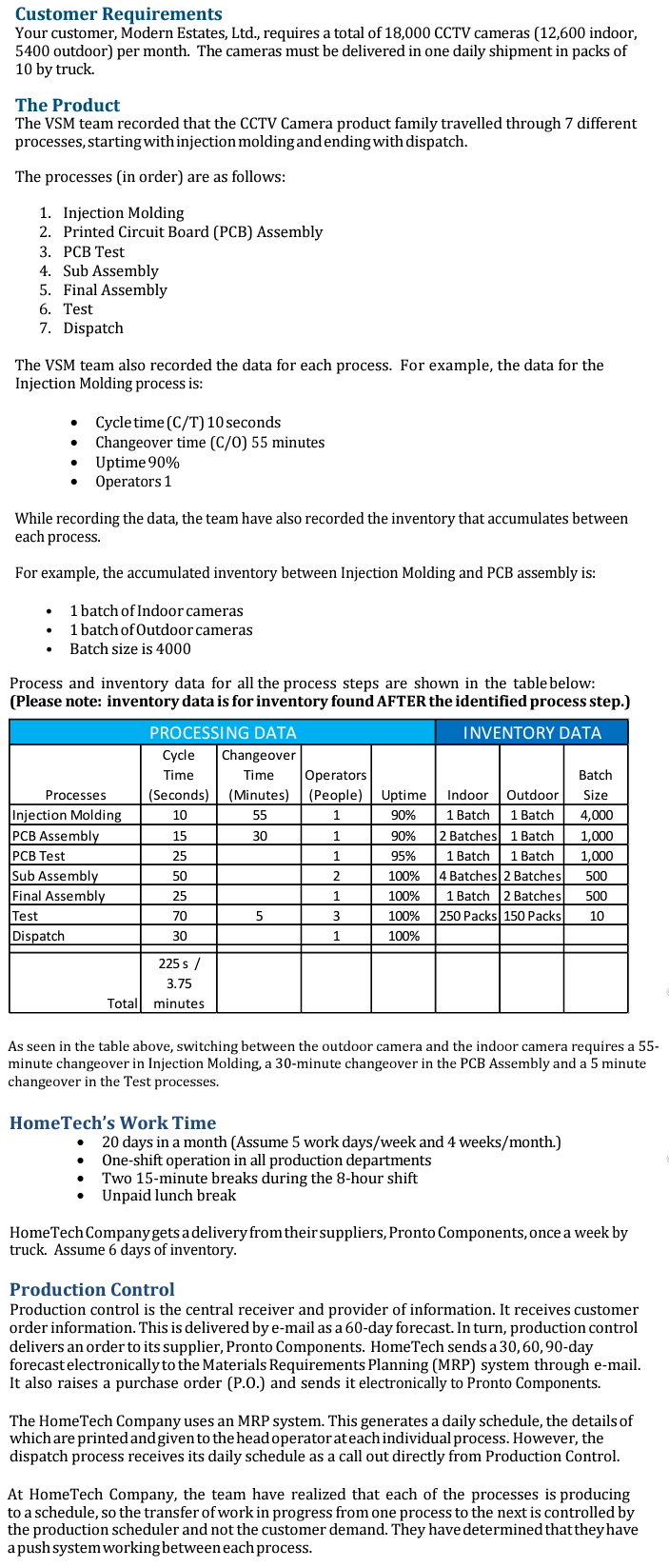

Customer Requirements Your customer, Modern Estates, Ltd., requires a total of 18,000 CCTV cameras [12,600 indoor, 5400 outdoor) per month. The cameras must be delivered in one daily shipment in packs of 10 by truck. The Product The VSM team recorded that the CCTV Camera product family travelled through 7 different processes, starting with injection molding and ending with dispatch. The processes (in order) are as follows: 1. Injection Molding 2. Printed Circuit Board (PCB) Assembly 3. PCB Test 4. Sub Assembly 5. Final Assembly 6. Test 7. Dispatch The VSM team also recorded the data for each process. For example, the data for the Injection Molding process is: - Cycletime (C/T) 10 seconds - Changeover time (C/0) 55 minutes - Uptime 90% - Operators 1 While recording the data, the team have also recorded the inventory that accumulates between each process. For example, the accumulated inventory between Injection Molding and PCB assembly is: - 1 batch of Indoor cameras - 1 batch of Outdoor cameras - Batch size is 4000 Process and inventory data for all the process steps are shown in the tablebelow: (Please note: inventory data is for inventory found AFTER the identified process step.) As seen in the table above, switching between the outdoor camera and the indoor camera requires a 55minute changeover in Injection Molding, a 30-minute changeover in the PCB Assembly and a 5 minute changeover in the Test processes. HomeTech's Work Time - 20 days in a month (Assume 5 work days/week and 4 weeks/month.) - One-shift operation in all production departments - Two 15-minute breaks during the 8-hour shift - Unpaid lunch break HomeTech Company gets a delivery from their suppliers, Pronto Components, once a week by truck. Assume 6 days of inventory. Production Control Production control is the central receiver and provider of information. It receives customer order information. This is delivered by e-mail as a 60-day forecast. In turn, production control delivers an order to its supplier, Pronto Components. HomeTech sends a 30,60, 90-day forecast electronically to the Materials Requirements Planning (MRP) system through e-mail. It also raises a purchase order (P.O.) and sends it electronically to Pronto Components. The HomeTech Company uses an MRP system. This generates a daily schedule, the details of which are printed and given to the head operator at each individual process. However, the dispatch process receives its daily schedule as a call out directly from Production Control. At HomeTech Company, the team have realized that each of the processes is producing to a schedule, so the transfer of work in progress from one process to the next is controlled by the production scheduler and not the customer demand. They have determined that they have a push system working between each process

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts