Question: help pls :/ (10 points) A manufacturing item (handle) has the following master production schedule, product structure and the resource profile. Week 1 0 Week

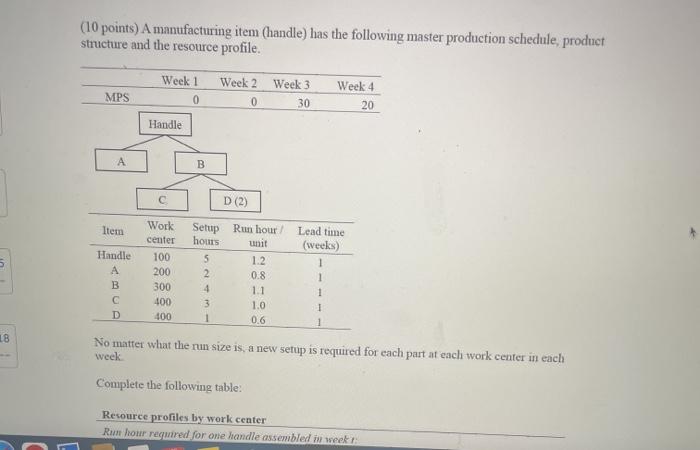

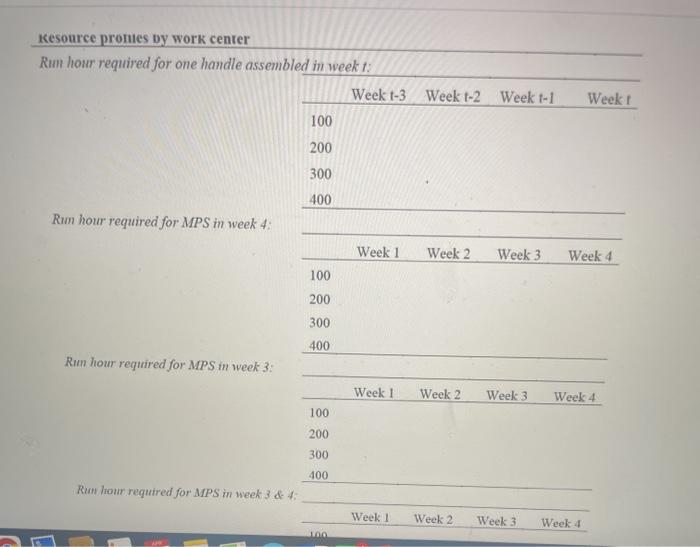

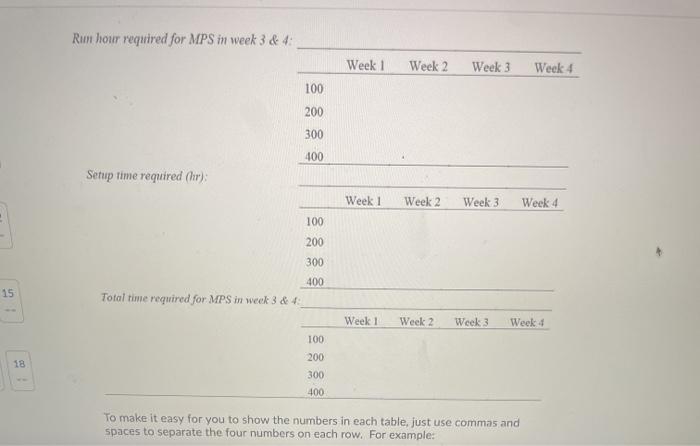

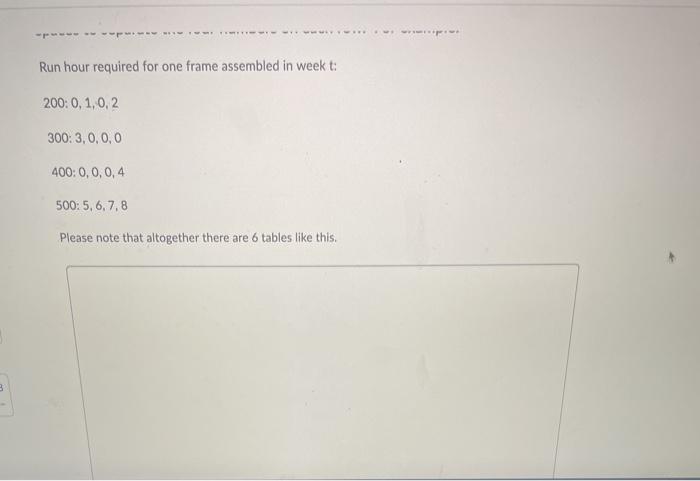

(10 points) A manufacturing item (handle) has the following master production schedule, product structure and the resource profile. Week 1 0 Week 2 0 MPS Week 3 30 Week 4 20 Handle B c D (2) Item 5 Handle A B Work center 100 200 300 400 400 Setup Run hour' Lead time hours unit (weeks) 5 1.2 1 2 0.8 1 4 11 1 3 1.0 1 1 0.6 1 D 18 No matter what the run size is a new setup is required for each part at each work center in each week Complete the following table: Resource profiles by work center Run hour required for one handle assembled in weet Resource prones by work center Run hour required for one handle assembled in week 1: Week t-3 Week 1-2 100 Week 1-1 Weekt 200 300 400 Run hour required for MPS in week 4: Week 1 Week 2 Week 3 Week 4 100 200 300 400 Run hour required for MPS in week 3: Week 1 Week 2 Week 3 Week 4 100 200 300 400 Rulour required for MPS in week 3&4: Week! Week 2 Week 3 Week 4 10 Run hour required for MPS in week 3 & 4: Week 1 Week 2 Week 3 Week 4 100 200 300 400 Setup time required (hr) Week 1 Week 2 Week 3 Week 4 100 200 300 400 15 Total time required for MPS in week 3 & 4 Week 1 Week 2 Week 3 Week 4 100 200 18 300 400 To make it easy for you to show the numbers in each table, just use commas and spaces to separate the four numbers on each row. For example: . Run hour required for one frame assembled in weekt: 200: 0,1,0,2 300:3,0,0,0 400:0, 0, 0,4 500:5,6,7,8 Please note that altogether there are 6 tables like this. 3 (10 points) A manufacturing item (handle) has the following master production schedule, product structure and the resource profile. Week 1 0 Week 2 0 MPS Week 3 30 Week 4 20 Handle B c D (2) Item 5 Handle A B Work center 100 200 300 400 400 Setup Run hour' Lead time hours unit (weeks) 5 1.2 1 2 0.8 1 4 11 1 3 1.0 1 1 0.6 1 D 18 No matter what the run size is a new setup is required for each part at each work center in each week Complete the following table: Resource profiles by work center Run hour required for one handle assembled in weet Resource prones by work center Run hour required for one handle assembled in week 1: Week t-3 Week 1-2 100 Week 1-1 Weekt 200 300 400 Run hour required for MPS in week 4: Week 1 Week 2 Week 3 Week 4 100 200 300 400 Run hour required for MPS in week 3: Week 1 Week 2 Week 3 Week 4 100 200 300 400 Rulour required for MPS in week 3&4: Week! Week 2 Week 3 Week 4 10 Run hour required for MPS in week 3 & 4: Week 1 Week 2 Week 3 Week 4 100 200 300 400 Setup time required (hr) Week 1 Week 2 Week 3 Week 4 100 200 300 400 15 Total time required for MPS in week 3 & 4 Week 1 Week 2 Week 3 Week 4 100 200 18 300 400 To make it easy for you to show the numbers in each table, just use commas and spaces to separate the four numbers on each row. For example: . Run hour required for one frame assembled in weekt: 200: 0,1,0,2 300:3,0,0,0 400:0, 0, 0,4 500:5,6,7,8 Please note that altogether there are 6 tables like this. 3

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts