Question: Help! Read the scenario below. Then construct and interpret the appropriate control charts. Exercise Objective: Construct and interpret statistical process control charts. Course Learning Objective:

Help!

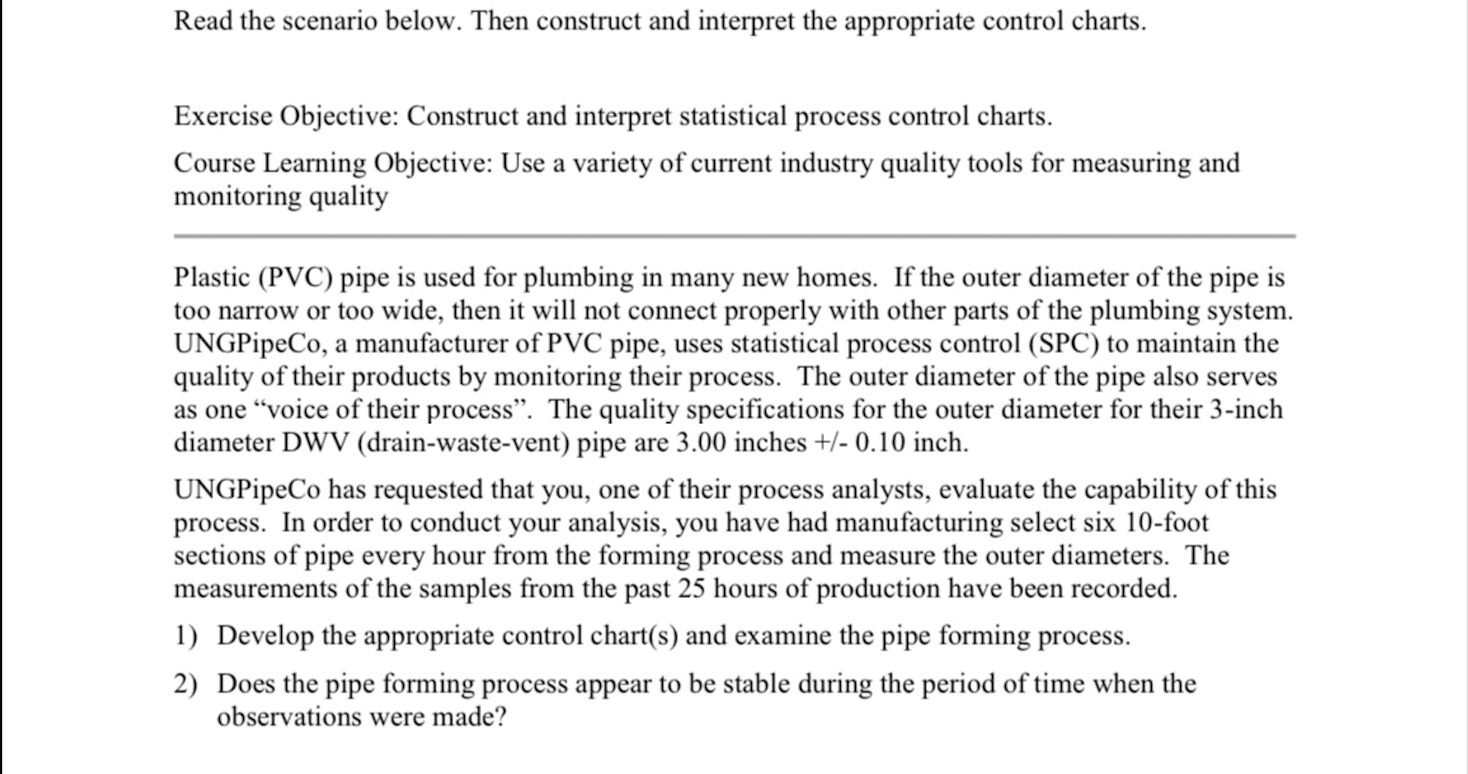

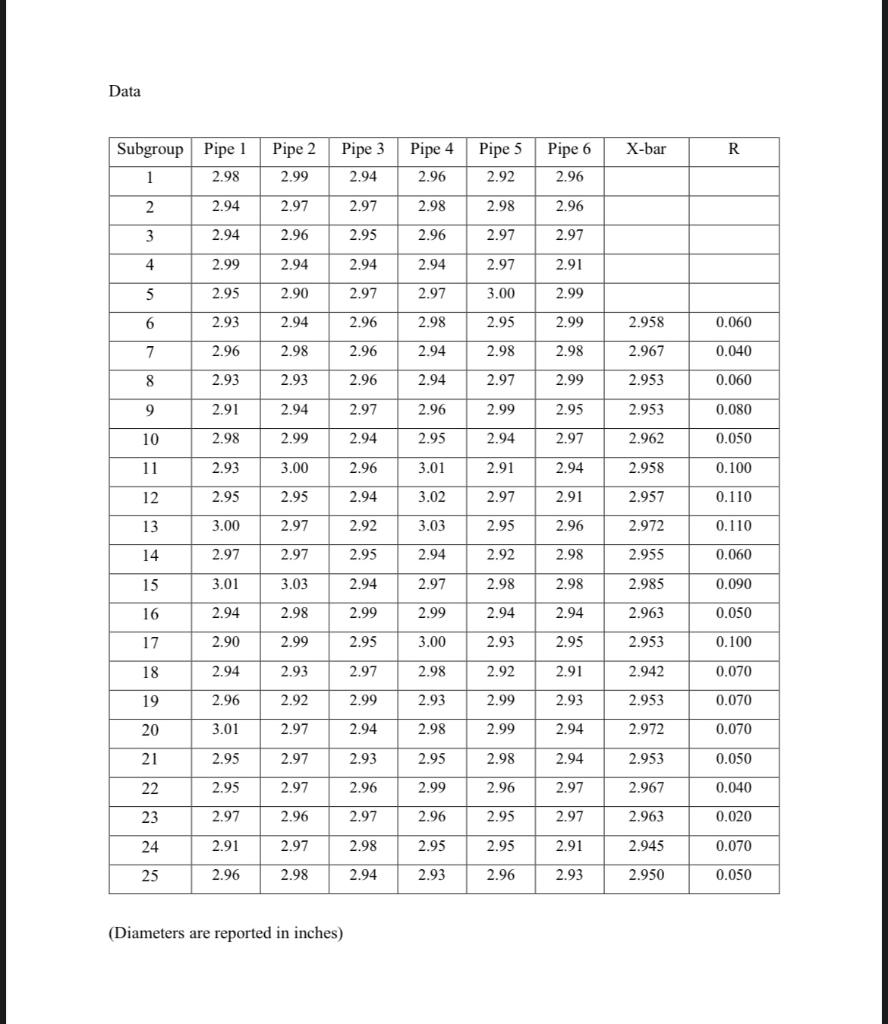

Read the scenario below. Then construct and interpret the appropriate control charts. Exercise Objective: Construct and interpret statistical process control charts. Course Learning Objective: Use a variety of current industry quality tools for measuring and monitoring quality Plastic (PVC) pipe is used for plumbing in many new homes. If the outer diameter of the pipe is too narrow or too wide, then it will not connect properly with other parts of the plumbing system. UNGPipeCo, a manufacturer of PVC pipe, uses statistical process control (SPC) to maintain the quality of their products by monitoring their process. The outer diameter of the pipe also serves as one voice of their process". The quality specifications for the outer diameter for their 3-inch diameter DWV (drain-waste-vent) pipe are 3.00 inches +/-0.10 inch. UNGPipeCo has requested that you, one of their process analysts, evaluate the capability of this process. In order to conduct your analysis, you have had manufacturing select six 10-foot sections of pipe every hour from the forming process and measure the outer diameters. The measurements of the samples from the past 25 hours of production have been recorded. 1) Develop the appropriate control chart(s) and examine the pipe forming process. 2) Does the pipe forming process appear to be stable during the period of time when the observations were made? Data Pipe 2 Pipe 3 Pipe 4 Pipe 6 X-bar R Subgroup Pipe 1 1 2.98 Pipe 5 2.92 2.99 2.94 2.96 2.96 2 2.94 2.97 2.97 2.98 2.98 2.96 3 2.94 2.96 2.95 2.96 2.97 2.97 4 2.99 2.94 2.94 2.94 2.97 2.91 5 2.95 2.90 2.97 2.97 3.00 2.99 6 2.93 2.94 2.96 2.98 2.95 2.99 2.958 0.060 7 2.96 2.98 2.96 2.94 2.98 2.98 2.967 0.040 oc 2.93 2.93 2.96 2.94 2.97 2.99 2.953 0.060 9 2.91 2.94 2.97 2.96 2.99 2.95 2.953 0.080 10 2.98 2.99 2.94 2.95 2.94 2.97 2.962 0.050 11 2.93 3.00 2.96 3.01 2.91 2.94 2.958 0.100 12 2.95 2.95 2.94 3.02 2.97 2.91 2.957 0.110 13 3.00 2.97 2.92 3.03 2.95 2.96 2.972 0.110 14 2.97 2.97 2.95 2.94 2.92 2.98 2.955 0.060 15 3.01 3.03 2.94 2.97 2.98 2.98 2.985 0.090 16 2.94 2.98 2.99 2.99 2.94 2.94 2.963 0.050 17 2.90 2.99 2.95 3.00 2.93 2.95 2.953 0.100 18 2.94 2.93 2.97 2.98 2.92 2.91 2.942 0.070 19 2.96 2.92 2.99 2.93 2.99 2.93 2.953 0.070 20 3.01 2.97 2.94 2.98 2.99 2.94 2.972 0.070 21 2.95 2.97 2.93 2.95 2.98 2.94 2.953 0.050 22 2.95 2.97 2.96 2.99 2.96 2.97 2.967 0.040 23 2.97 2.96 2.97 2.96 2.95 2.97 2.963 0.020 24 2.91 2.97 2.98 2.95 2.95 2.91 2.945 0.070 25 2.96 2.98 2.94 1 2.93 2.96 2.93 2.950 0.0 (Diameters are reported in inches)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts