Question: help with number 3, please Try to develop a possible hybrid plan that would accomplish the task with smaller total costs than either level or

help with number 3, please

Try to develop a possible hybrid plan that would accomplish the task with smaller total costs than either level or chase.

(I've attached work for questions 1 and 2 for reference).

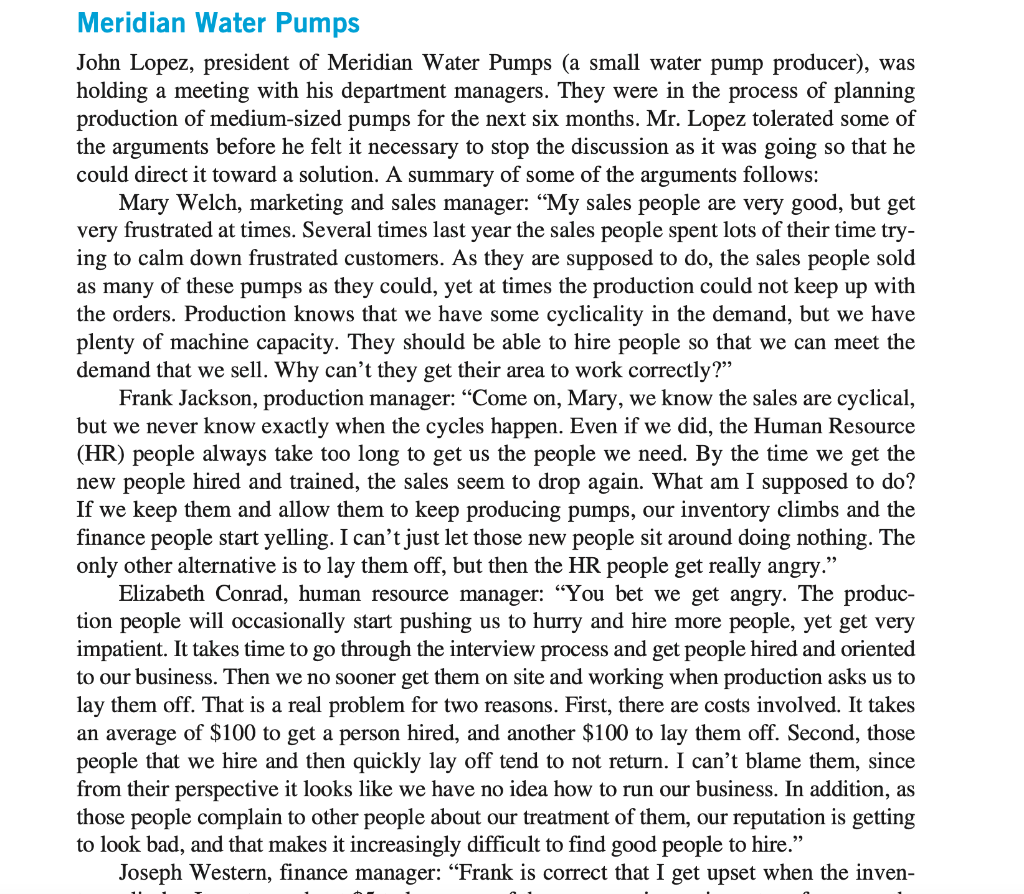

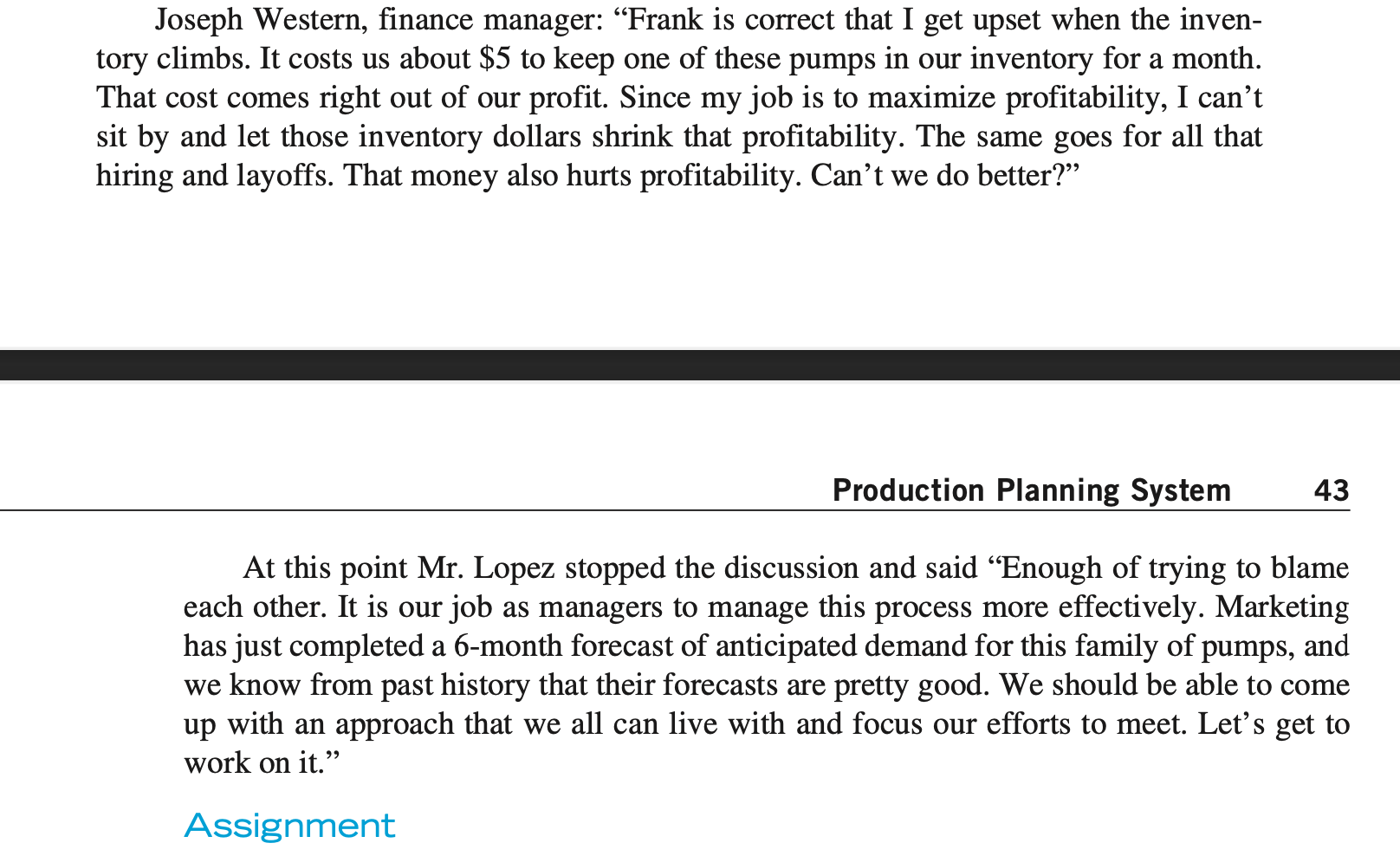

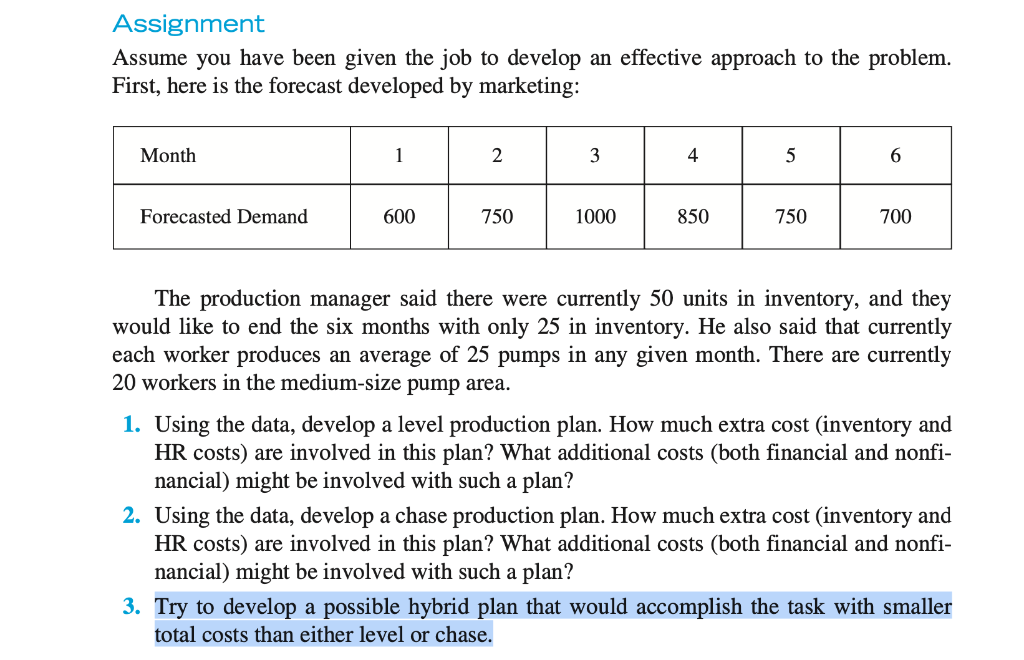

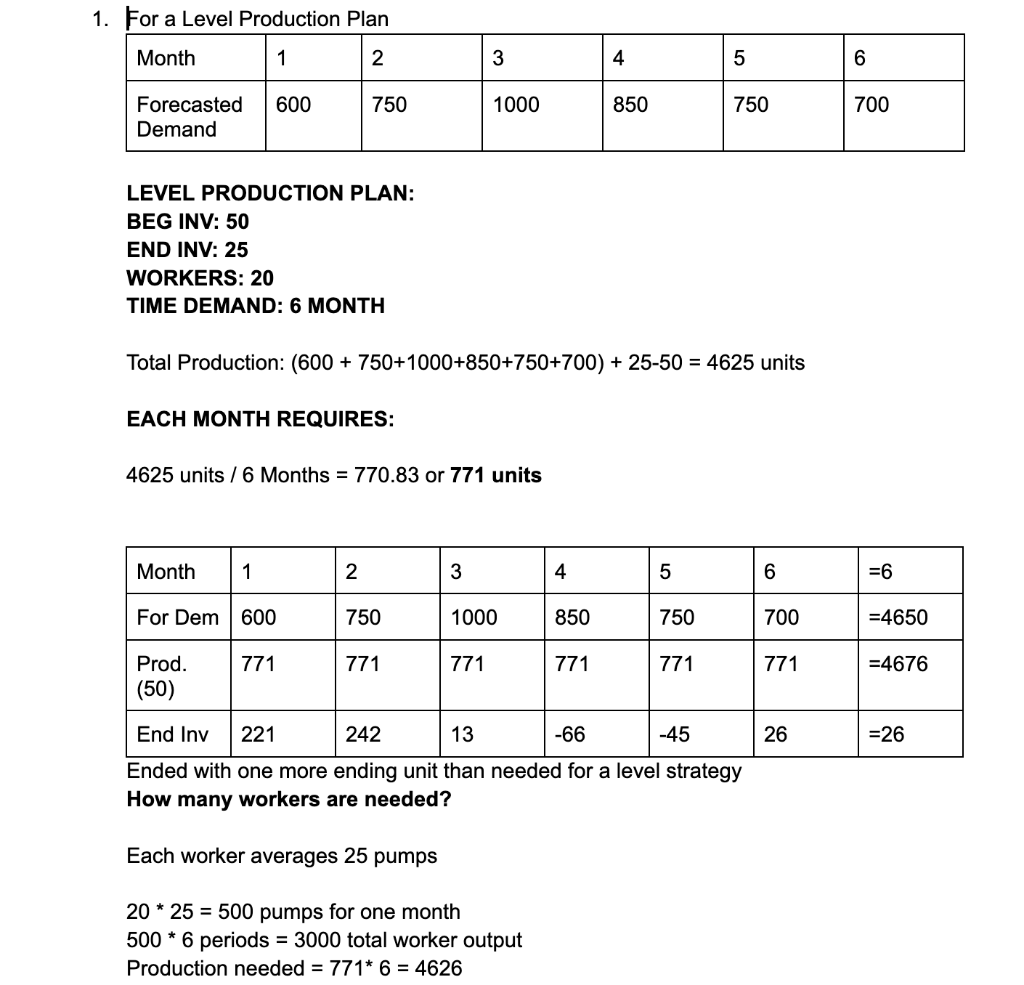

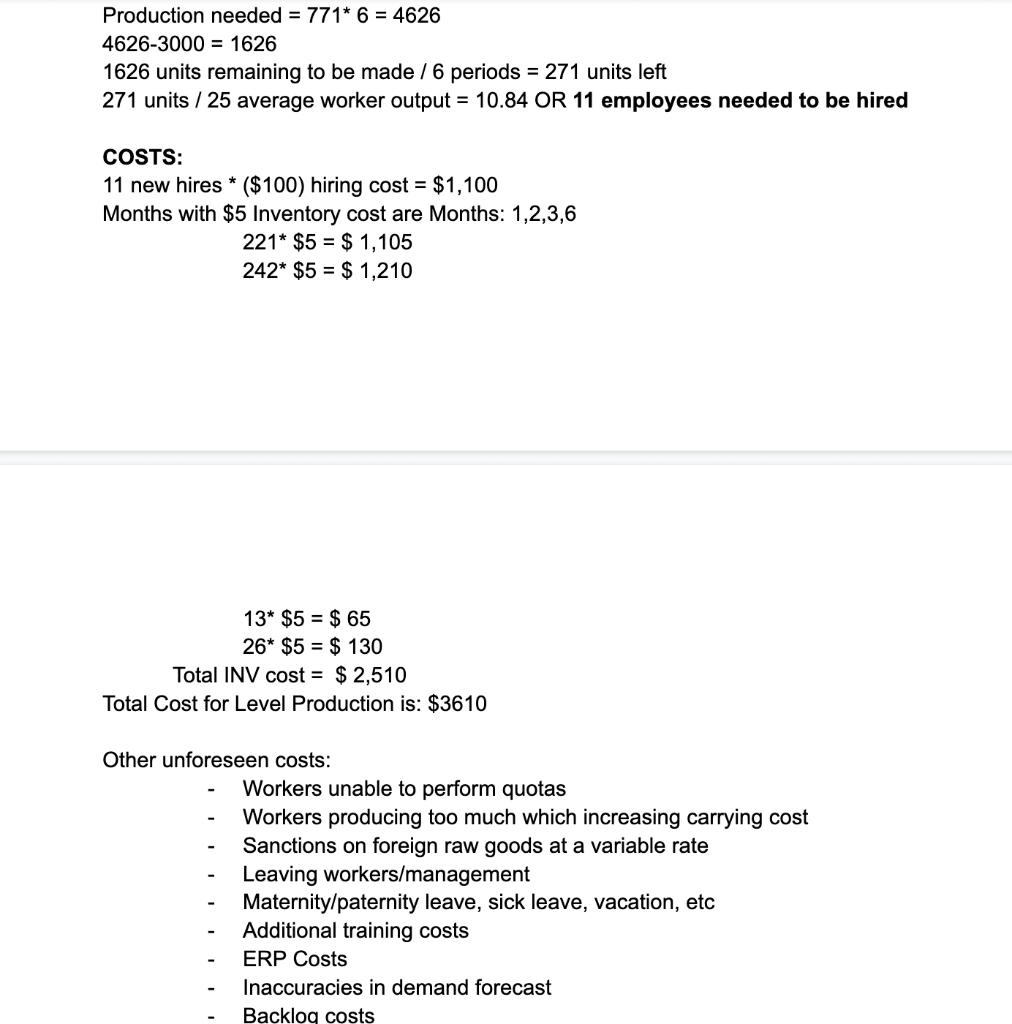

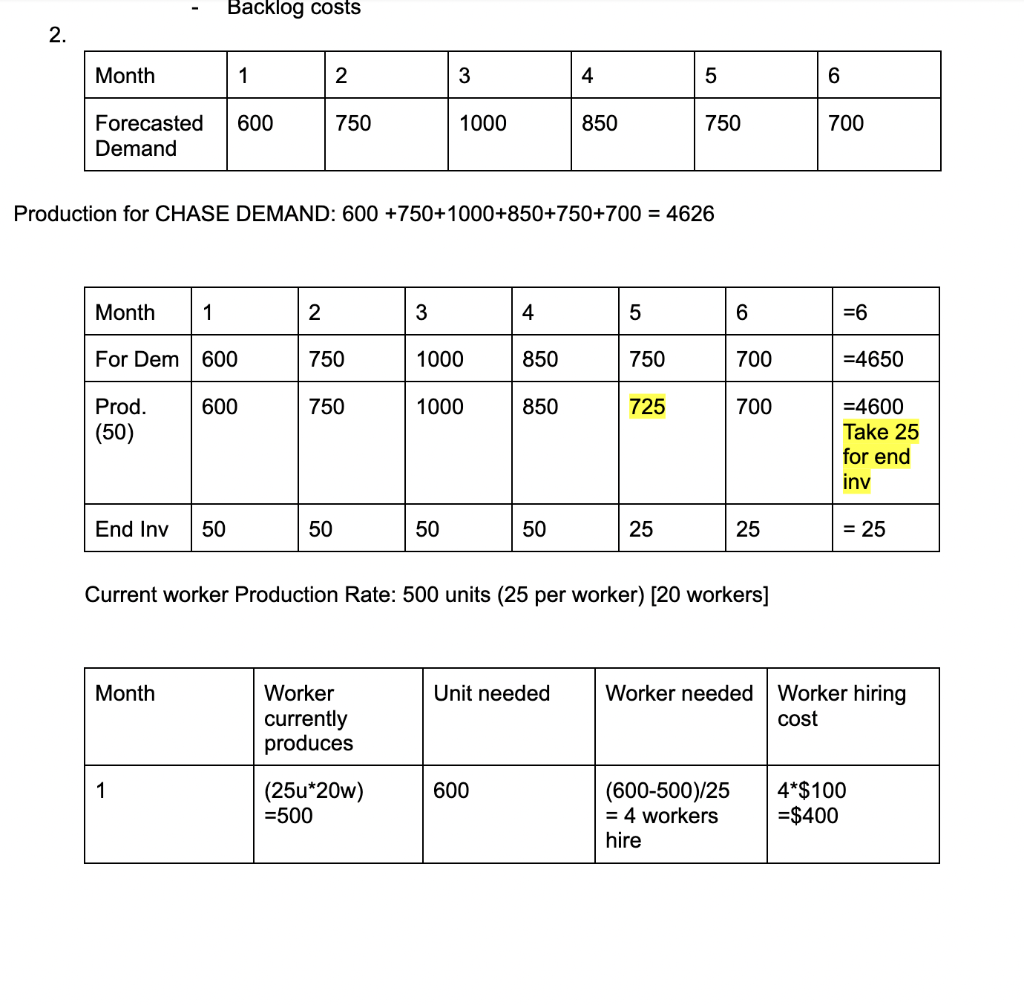

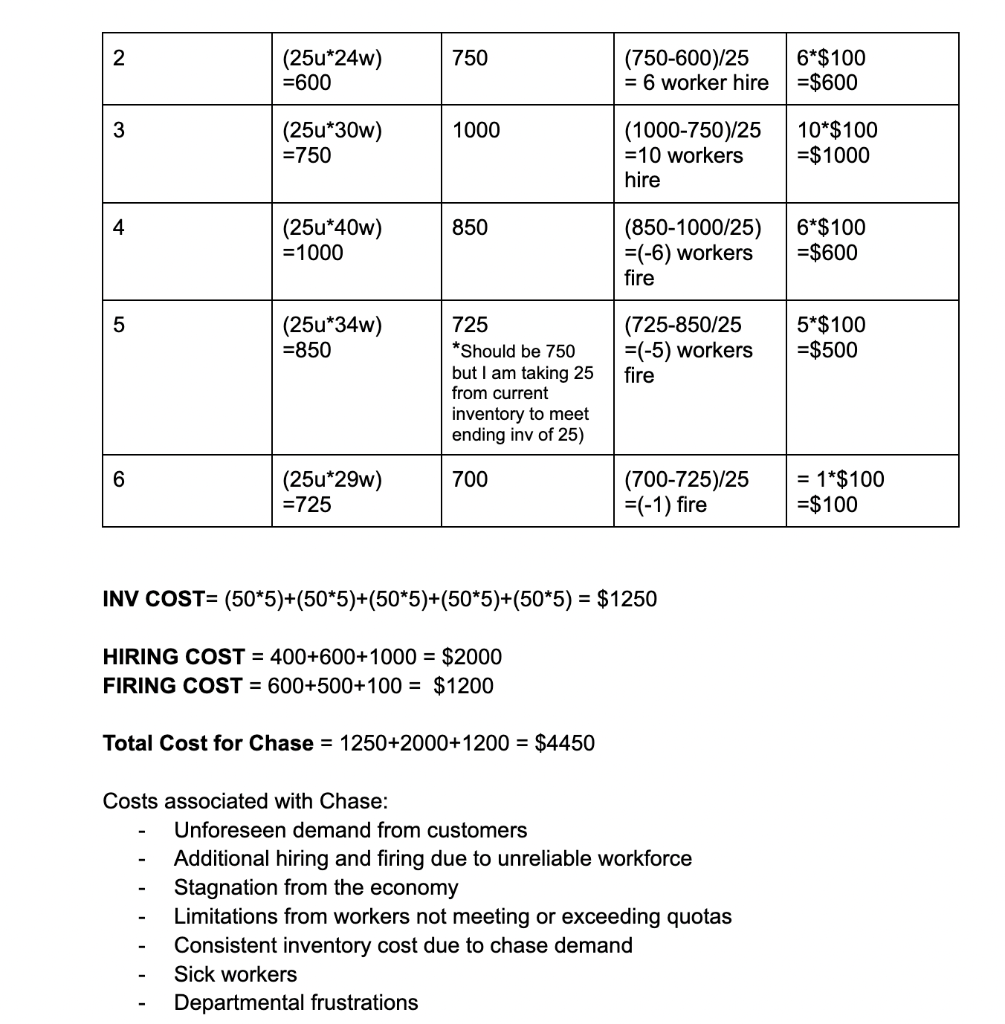

Meridian Water Pumps John Lopez, president of Meridian Water Pumps (a small water pump producer), was holding a meeting with his department managers. They were in the process of planning production of medium-sized pumps for the next six months. Mr. Lopez tolerated some of the arguments before he felt it necessary to stop the discussion as it was going so that he could direct it toward a solution. A summary of some of the arguments follows: Mary Welch, marketing and sales manager: My sales people are very good, but get very frustrated at times. Several times last year the sales people spent lots of their time try- ing to calm down frustrated customers. As they are supposed to do, the sales people sold as many of these pumps as they could, yet at times the production could not keep up with the orders. Production knows that we have some cyclicality in the demand, but we have plenty of machine capacity. They should be able to hire people so that we can meet the demand that we sell. Why can't they get their area to work correctly? Frank Jackson, production manager: Come on, Mary, we know the sales are cyclical, but we never know exactly when the cycles happen. Even if we did, the Human Resource (HR) people always take too long to get us the people we need. By the time we get the new people hired and trained, the sales seem to drop again. What am I supposed to do? If we keep them and allow them to keep producing pumps, our inventory climbs and the finance people start yelling. I can't just let those new people sit around doing nothing. The only other alternative is to lay them off, but then the HR people get really angry." Elizabeth Conrad, human resource manager: You bet we get angry. The produc- tion people will occasionally start pushing us to hurry and hire more people, yet get very impatient. It takes time to go through the interview process and get people hired and oriented to our business. Then we no sooner get them on site and working when production asks us to lay them off. That is a real problem for two reasons. First, there are costs involved. It takes an average of $100 to get a person hired, and another $100 to lay them off. Second, those people that we hire and then quickly lay off tend to not return. I can't blame them, since from their perspective it looks like we have no idea how to run our business. In addition, as those people complain to other people about our treatment of them, our reputation is getting to look bad, and that makes it increasingly difficult to find good people to hire. Joseph Western, finance manager: Frank is correct that I get upset when the inven- a Joseph Western, finance manager: Frank is correct that I get upset when the inven- tory climbs. It costs us about $5 to keep one of these pumps in our inventory for a month. That cost comes right out of our profit. Since my job is to maximize profitability, I can't sit by and let those inventory dollars shrink that profitability. The same goes for all that hiring and layoffs. That money also hurts profitability. Can't we do better? Production Planning System 43 At this point Mr. Lopez stopped the discussion and said Enough of trying to blame each other. It is our job as managers to manage this process more effectively. Marketing has just completed a 6-month forecast of anticipated demand for this family of pumps, and we know from past history that their forecasts are pretty good. We should be able to come up with an approach that we all can live with and focus our efforts to meet. Let's get to work on it. Assignment Assignment Assume you have been given the job to develop an effective approach to the problem. First, here is the forecast developed by marketing: Month 1 2 3 4 5 6 Forecasted Demand 600 750 1000 850 750 700 The production manager said there were currently 50 units in inventory, and they would like to end the six months with only 25 in inventory. He also said that currently each worker produces an average of 25 pumps in any given month. There are currently 20 workers in the medium-size pump area. 1. Using the data, develop a level production plan. How much extra cost inventory and HR costs) are involved in this plan? What additional costs (both financial and nonfi- nancial) might be involved with such a plan? 2. Using the data, develop a chase production plan. How much extra cost (inventory and HR costs) are involved in this plan? What additional costs (both financial and nonfi- nancial) might be involved with such a plan? 3. Try to develop a possible hybrid plan that would accomplish the task with smaller total costs than either level or chase. 1. For a Level Production Plan Month 1 2 3 4 5 01 6 600 750 1000 850 750 700 Forecasted Demand LEVEL PRODUCTION PLAN: BEG INV: 50 END INV: 25 WORKERS: 20 TIME DEMAND: 6 MONTH Total Production: (600 + 750+1000+850+750+700) + 25-50 = 4625 units EACH MONTH REQUIRES: 4625 units / 6 Months = 770.83 or 771 units Month 1 2 3 4 5 6 =6 For Dem600 750 1000 850 750 700 =4650 771 771 771 771 771 771 =4676 Prod. (50) End Iny 221 242 13 -66 -45 26 =26 Ended with one more ending unit than needed for a level strategy How many workers are needed? Each worker averages 25 pumps 20 * 25 = 500 pumps for one month 500 * 6 periods = 3000 total worker output Production needed = 771* 6 = 4626 Production needed = 771* 6 = 4626 4626-3000 = 1626 1626 units remaining to be made / 6 periods = 271 units left 271 units / 25 average worker output = 10.84 OR 11 employees needed to be hired COSTS: 11 new hires * ($100) hiring cost = $1,100 Months with $5 Inventory cost are Months: 1,2,3,6 221* $5 = $ 1,105 242* $5 = $ 1,210 13* $5 = $ 65 26* $5 = $ 130 Total INV cost = $ 2,510 Total Cost for Level Production is: $3610 Other unforeseen costs: Workers unable to perform quotas Workers producing too much which increasing carrying cost Sanctions on foreign raw goods at a variable rate Leaving workers/management Maternity/paternity leave, sick leave, vacation, etc Additional training costs ERP Costs Inaccuracies in demand forecast Backlog costs Backlog costs 2. Month 1 2 3 4 5 6 600 750 1000 850 750 700 Forecasted Demand Production for CHASE DEMAND: 600 + 750+1000+850+750+700 = 4626 Month 1 2 3 4 5 6 =6 For Dem600 750 1000 850 750 700 =4650 600 750 1000 850 725 700 Prod. (50) =4600 Take 25 for end iny End Inv 50 50 50 50 25 25 = 25 Current worker Production Rate: 500 units (25 per worker) [20 workers] Month Unit needed Worker currently produces Worker needed Worker hiring cost 1 600 (25u*20w) =500 (600-500)/25 = 4 workers hire 4*$100 =$400 2 750 (25u*24w) =600 (750-600)/25 = 6 worker hire 6*$100 =$600 3 1000 (25u*30w) =750 (1000-750)/25 =10 workers hire 10*$100 =$1000 4 850 (25u*40w) =1000 (850-1000/25) =(-6) workers fire 6*$100 =$600 5 (25u*34w) =850 725 *Should be 750 but I am taking 25 from current inventory to meet ending inv of 25) (725-850/25 =(-5) workers fire 5*$100 =$500 6 700 (25u*29w) =725 (700-725)/25 =(-1) fire = 1*$100 =$100 INV COST= (50*5)+(50*5)+(50*5)+(50*5)+(50*5) = $1250 HIRING COST = 400+600+1000 = $2000 FIRING COST = 600+500+100 = $1200 Total Cost for Chase = 1250+2000+1200 = $4450 - Costs associated with Chase: Unforeseen demand from customers Additional hiring and firing due to unreliable workforce Stagnation from the economy Limitations from workers not meeting or exceeding quotas Consistent inventory cost due to chase demand Sick workers Departmental frustrationsStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts