Question: helpImagine a food processing facility where a crucial step involves heating a sugar solution. In this operation, a specialized stainless - steel jacketed pan, with

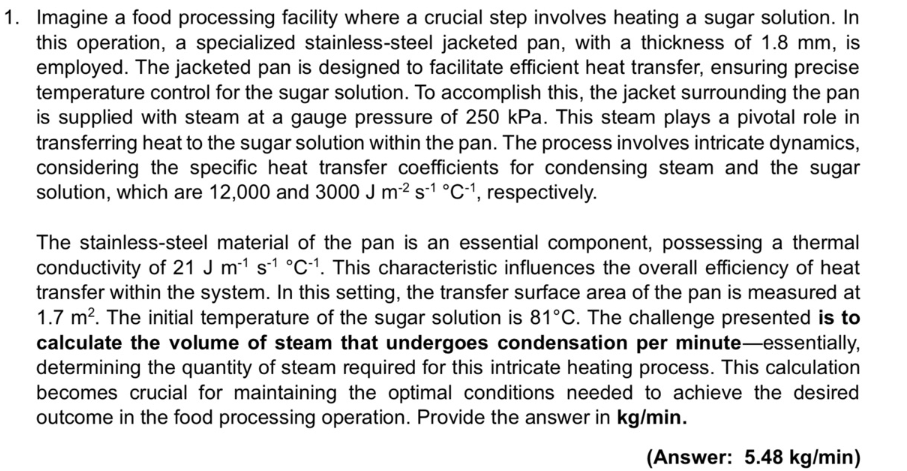

helpImagine a food processing facility where a crucial step involves heating a sugar solution. In

this operation, a specialized stainlesssteel jacketed pan, with a thickness of is

employed. The jacketed pan is designed to facilitate efficient heat transfer, ensuring precise

temperature control for the sugar solution. To accomplish this, the jacket surrounding the pan

is supplied with steam at a gauge pressure of kPa. This steam plays a pivotal role in

transferring heat to the sugar solution within the pan. The process involves intricate dynamics,

considering the specific heat transfer coefficients for condensing steam and the sugar

solution, which are and respectively.

The stainlesssteel material of the pan is an essential component, possessing a thermal

conductivity of This characteristic influences the overall efficiency of heat

transfer within the system. In this setting, the transfer surface area of the pan is measured at

The initial temperature of the sugar solution is The challenge presented is to

calculate the volume of steam that undergoes condensation per minuteessentially,

determining the quantity of steam required for this intricate heating process. This calculation

becomes crucial for maintaining the optimal conditions needed to achieve the desired

outcome in the food processing operation. Provide the answer in

Answer:

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock