Question: Hi, I could really use help with this problem! I'd really appreciate any help I'm given. and d, respectively? Do not attempt to use solver

Hi, I could really use help with this problem! I'd really appreciate any help I'm given.

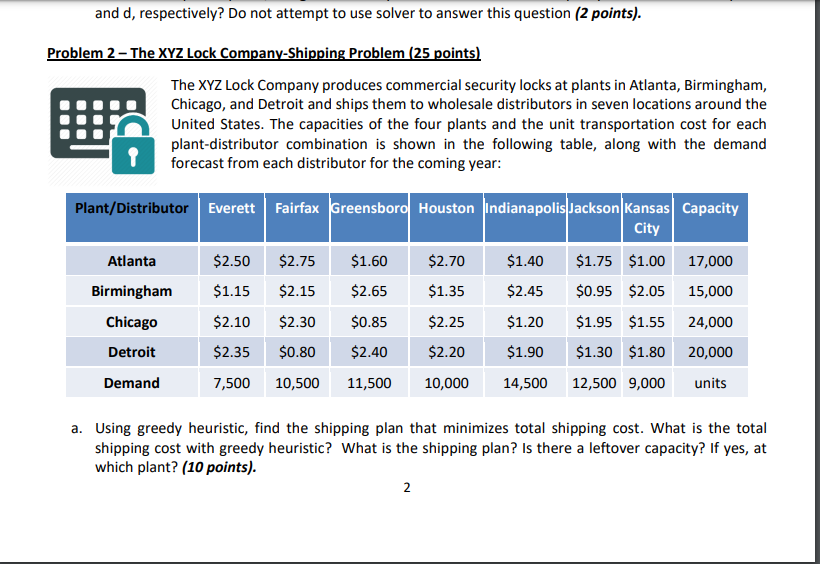

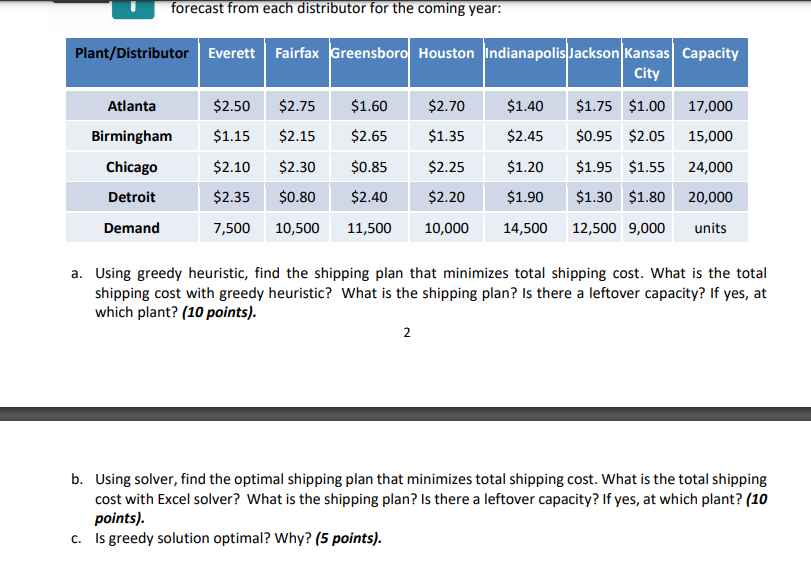

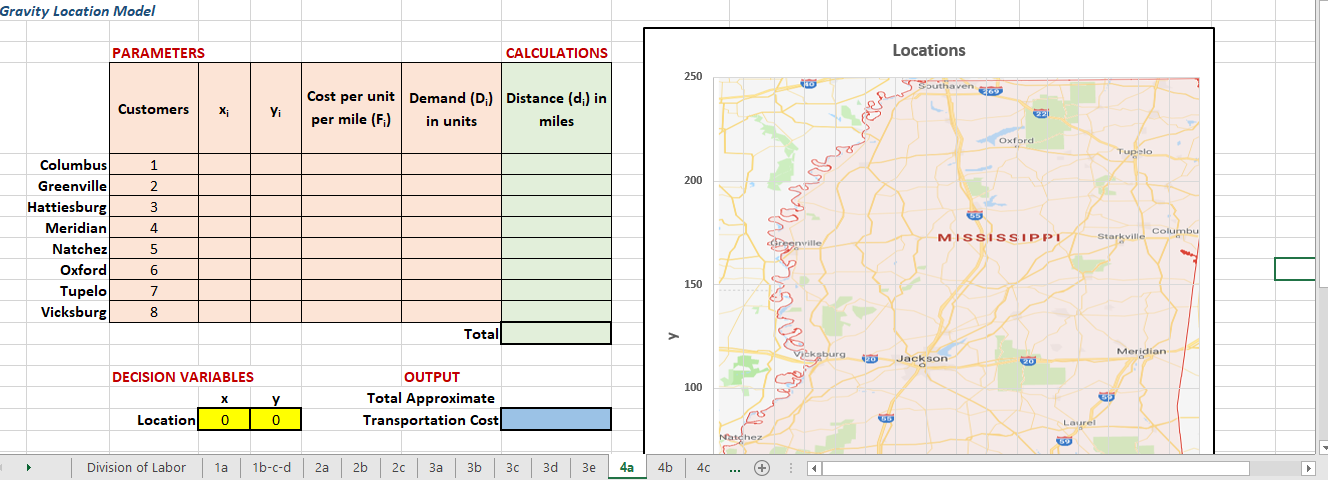

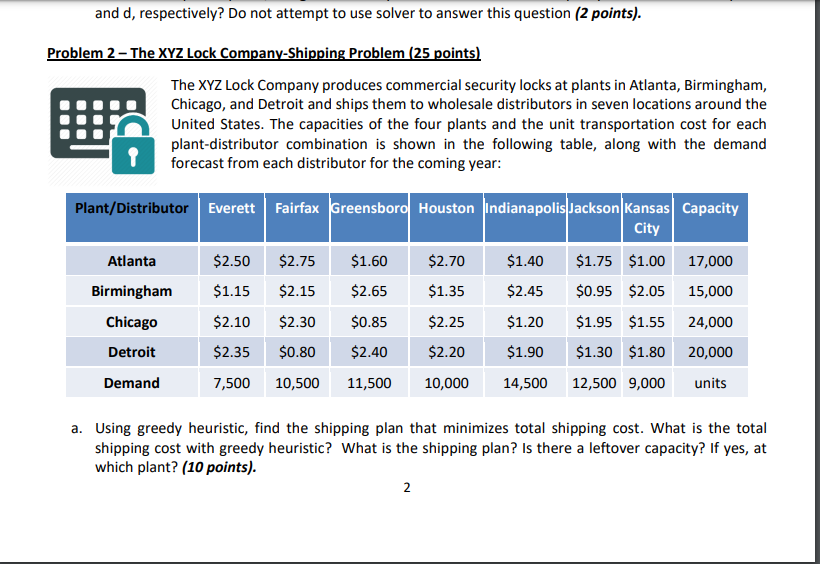

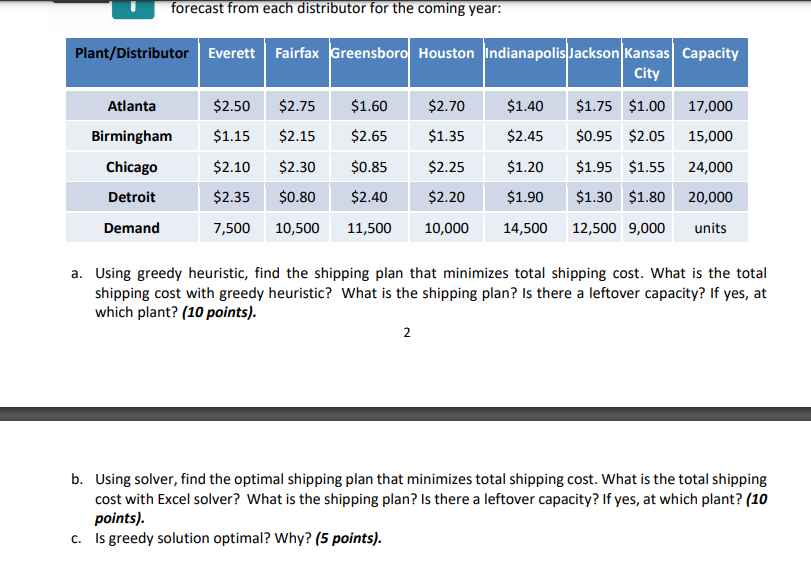

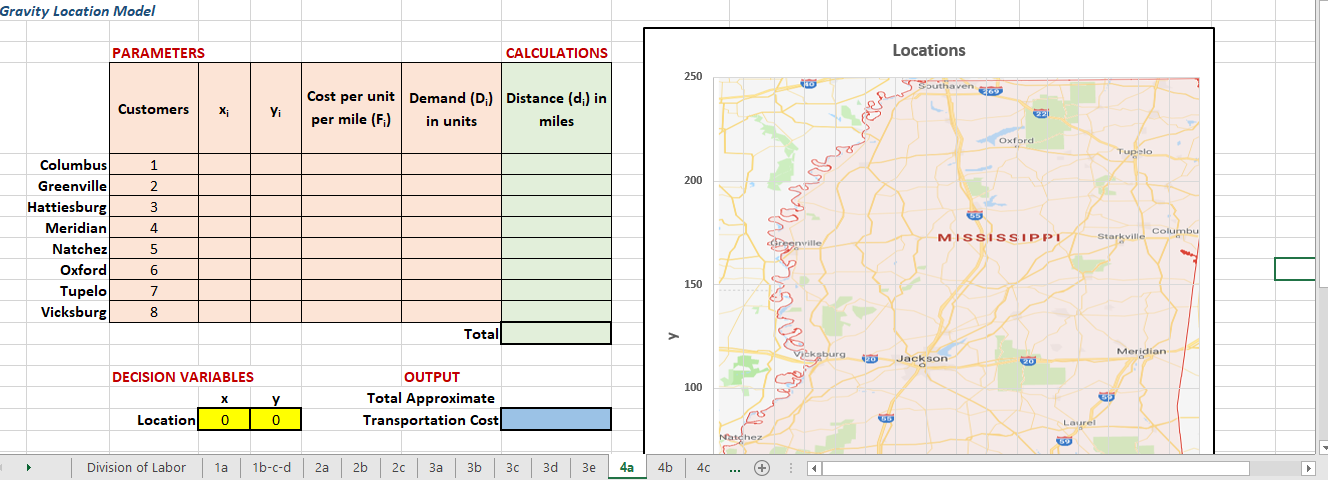

and d, respectively? Do not attempt to use solver to answer this question (2 points). Problem 2 - The XYZ Lock Company-Shipping Problem (25 points) The XYZ Lock Company produces commercial security locks at plants in Atlanta, Birmingham, Chicago, and Detroit and ships them to wholesale distributors in seven locations around the United States. The capacities of the four plants and the unit transportation cost for each plant-distributor combination is shown in the following table, along with the demand forecast from each distributor for the coming year: Plant/Distributor Everett Fairfax Greensboro Houston Indianapolis Jackson Kansas Capacity City $1.60 $2.75 $2.15 $1.40 $2.45 Atlanta Birmingham Chicago Detroit $2.50 $1.15 $2.10 $2.35 $2.65 $0.85 $2.30 $0.80 10,500 $2.70 $1.35 $2.25 $2.20 10,000 $1.75 $1.00 17,000 $0.95 $2.05 15,000 $1.95 $1.55 24,000 $1.30 $1.80 20,000 12,500 9,000 units $1.20 $1.90 14,500 $2.40 11,500 Demand 7,500 a. Using greedy heuristic, find the shipping plan that minimizes total shipping cost. What is the total shipping cost with greedy heuristic? What is the shipping plan? Is there a leftover capacity? If yes, at which plant? (10 points). 2 forecast from each distributor for the coming year: Plant/Distributor Everett Fairfax Greensboro Houston Indianapolis Jackson Kansas Capacity City $2.75 $1.60 $2.50 $1.15 $2.70 $1.35 $1.40 $2.45 $2.15 $2.65 Atlanta Birmingham Chicago Detroit $1.75 $1.00 17,000 $0.95 $2.05 15,000 $1.95 $1.55 24,000 $1.30 $1.80 20,000 $2.10 $2.30 $0.85 $2.25 $1.20 $2.35 $0.80 $2.40 $2.20 $1.90 Demand 7,500 10,500 11,500 10,000 14,500 12,500 9,000 units a. Using greedy heuristic, find the shipping plan that minimizes total shipping cost. What is the total shipping cost with greedy heuristic? What is the shipping plan? Is there a leftover capacity? If yes, at which plant? (10 points). 2 b. Using solver, find the optimal shipping plan that minimizes total shipping cost. What is the total shipping cost with Excel solver? What is the shipping plan? Is there a leftover capacity? If yes, at which plant? (10 points). C. Is greedy solution optimal? Why? (5 points). Gravity Location Model PARAMETERS CALCULATIONS Locations 250 10 Southaven Customers X; Yi Cost per unit Demand (D) Distance (d:) in per mile (F.) in units miles 221 Oxford Tupalo 200 1 1 2 3 4 5 orarischarger Columbus Greenville Hattiesburg Meridian Natchez Oxford Tupelo Vicksburg 15 55 tegnville MISSISSIPPI Starkville Columbu 6 150 7 8 Total Meridian Vickyburg 40 Jackson DECISION VARIABLES 100 Y OUTPUT Total Approximate Transportation Cost Location 0 0 Laurel Natchez Division of Labor 1a 1b-c-d 2a 2b 2c 3b 3c 3d 3e 4a 4b 40 +