Question: Hills operations manager (see Problems 13.3 through 13.5) is also considering two mixed strategies for January August: Produce in overtime or subcontracting only when there

Hills operations manager (see Problems 13.3 through 13.5) is also considering two mixed strategies for January August: Produce in overtime or subcontracting only when there is no inventory. Plan D: Keep the current workforce stable at producing 1,600 units per month. Permit a maximum of 20% overtime at an additional cost of $50 per unit. A warehouse now constrains the maximum allowable inventory on hand to 400 units or less. Plan E: Keep the current workforce, which is producing 1,600 units per month, and subcontract to meet the rest of the demand. Evaluate plans D and E and make a recommendation. Note: Do not produce in overtime if production or inventory are adequate to cover demand.

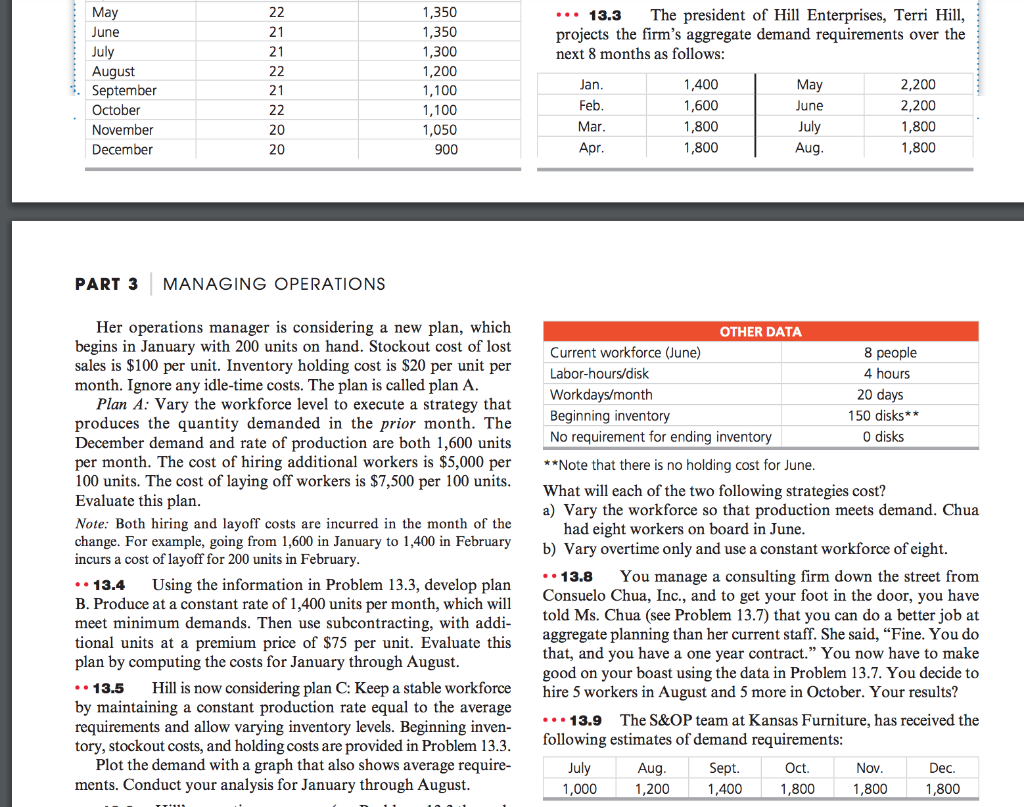

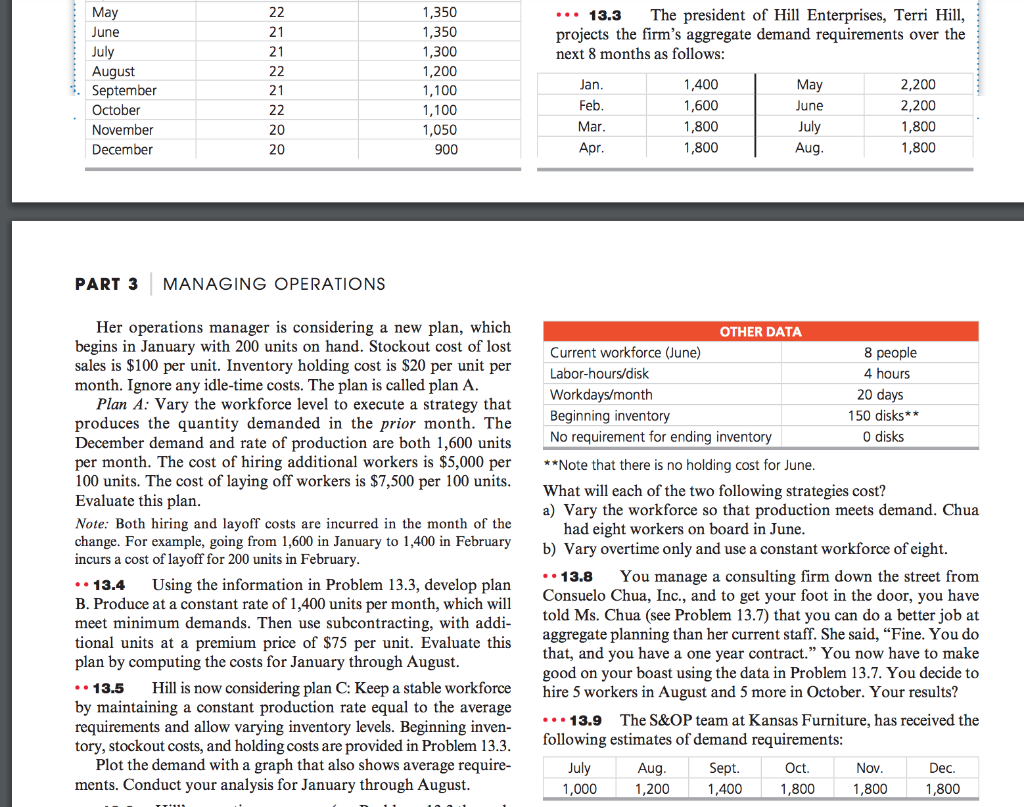

1,350 1,350 1,300 1,200 ... 13.3 The president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows: May June July August September October November December 1,100 1,100 1,050 900 Jan. Feb. Mar. Apr. 1,400 1,600 1,800 1,800 May June July Aug. 2,200 2,200 1,800 1,800 PART 3 MANAGING OPERATIONS Her operations manager is considering a new plan, which begins in January with 200 units on hand. Stockout cost of lost sales is $100 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan A. Plan A: Vary the workforce level to execute a strategy that produces the quantity demanded in the prior month. The December demand and rate of production are both 1,600 units per month. The cost of hiring additional workers is $5,000 per 100 units. The cost of laying off workers is $7,500 per 100 units. Evaluate this plan. Note: Both hiring and layoff costs are incurred in the month of the change. For example, going from 1,600 in January to 1,400 in February incurs a cost of layoff for 200 units in February. .. 13.4 Using the information in Problem 13.3, develop plan B. Produce at a constant rate of 1,400 units per month, which will meet minimum demands. Then use subcontracting, with addi- tional units at a premium price of $75 per unit. Evaluate this plan by computing the costs for January through August. .. 13.5 Hill is now considering plan C: Keep a stable workforce by maintaining a constant production rate equal to the average requirements and allow varying inventory levels. Beginning inven- tory, stockout costs, and holding costs are provided in Problem 13.3. Plot the demand with a graph that also shows average require- ments. Conduct your analysis for January through August. OTHER DATA Current workforce (June) 8 people Labor-hours/disk 4 hours Workdays/month 20 days Beginning inventory 150 disks** No requirement for ending inventory O disks **Note that there is no holding cost for June. What will each of the two following strategies cost? a) Vary the workforce so that production meets demand. Chua had eight workers on board in June. b) Vary overtime only and use a constant workforce of eight. .. 13.8 You manage a consulting firm down the street from Consuelo Chua, Inc., and to get your foot in the door, you have told Ms. Chua (see Problem 13.7) that you can do a better job at aggregate planning than her current staff. She said, "Fine. You do that, and you have a one year contract." You now have to make good on your boast using the data in Problem 13.7. You decide to hire 5 workers in August and 5 more in October. Your results? ... 13.9 The S&OP team at Kansas Furniture, has received the following estimates of demand requirements: July Aug. Sept. Oct Nov Dec. 1,000 1,200 1,400 1,800 1,800 1,800