Question: Homework: Modular Fixture Design You have been given a solid model of a finished component called Gearplate. You will be responsible for creating a modular

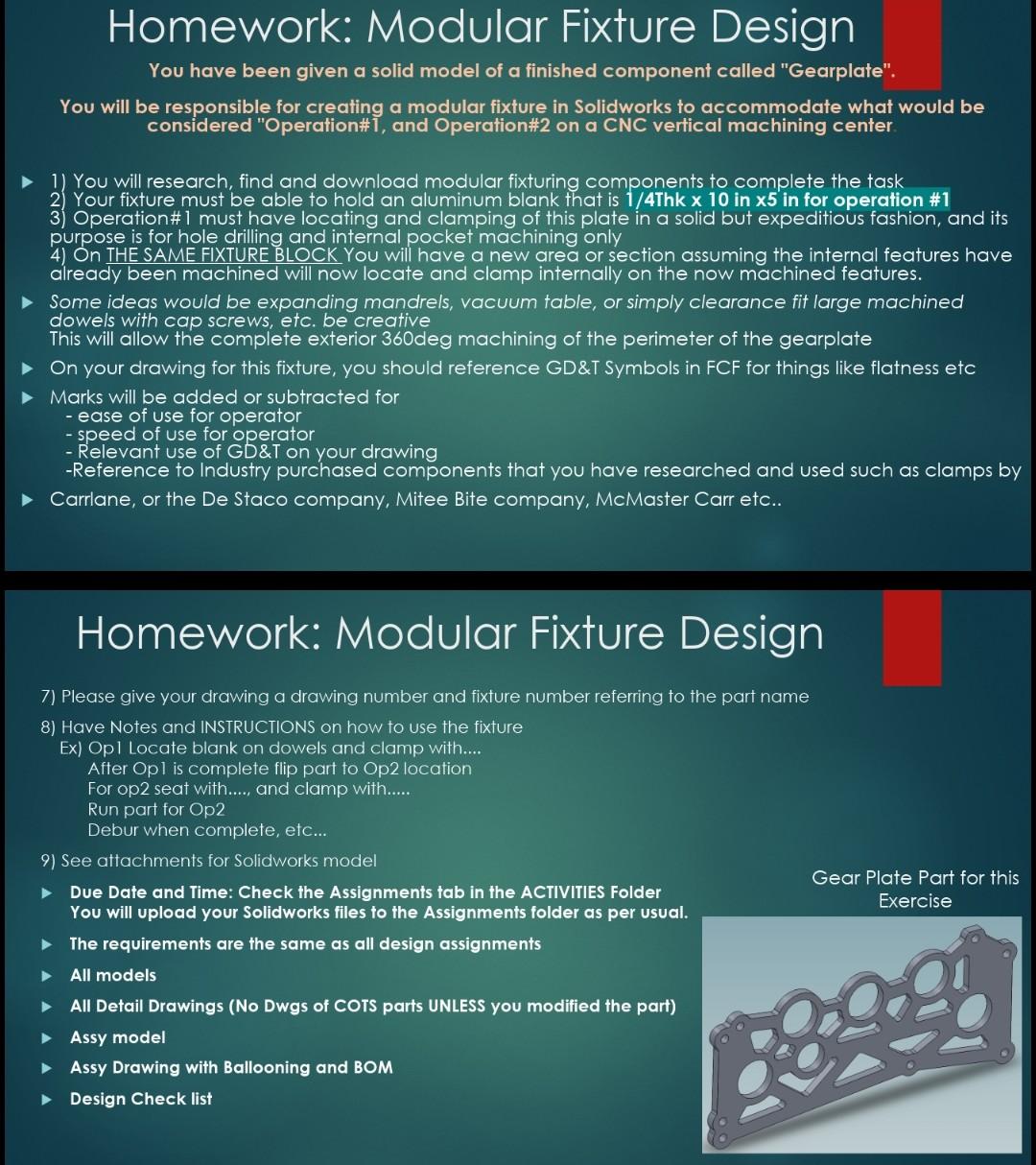

Homework: Modular Fixture Design You have been given a solid model of a finished component called "Gearplate". You will be responsible for creating a modular fixture in Solidworks to accommodate what would be considered "Operation#1, and Operation#2 on a CNC vertical machining center 1) You will research, find and download modular fixturing components to complete the task 2) Your fixture must be able to hold an aluminum blank that is 1/4Thk x 10 in x5 in for operation #1 3) Operation#1 must have locating and clamping of this plate in a solid but expeditious fashion, and its purpose is for hole drilling and internal pocket machining only 4) On THE SAME FIXTURE BLOCK You will have a new area or section assuming the internal features have already been machined will now locate and clamp internally on the now machined features. Some ideas would be expanding mandrels, vacuum table, or simply clearance fit large machined dowels with cap screws, etc. be creative This will allow the complete exterior 360deg machining of the perimeter of the gearplate On your drawing for this fixture, you should reference GD&T Symbols in FCF for things like flatness etc Marks will be added or subtracted for - ease of use for operator - speed of use for operator - Relevant use of GD&T on your drawing -Reference to Industry purchased components that you have researched and used such as clamps by Carrlane, or the De Staco company, Mitee Bite company, McMaster Carr etc.. Homework: Modular Fixture Design 7) Please give your drawing a drawing number and fixture number referring to the part name 8) Have Notes and INSTRUCTIONS on how to use the fixture Ex) Opl Locate blank on dowels and clamp with.... After Opl is complete flip part to Op2 location For op2 seat with...., and clamp with..... Run part for Op2 Debur when complete, etc... 9) See attachments for Solidworks model Gear Plate Part for this Due Date and Time: Check the Assignments tab in the ACTIVITIES Folder Exercise You will upload your Solidworks files to the Assignments folder as per usual. The requirements are the same as all design assignments All models All Detail Drawings (No Dwgs of Cots parts UNLESS you modified the part) Assy model Assy Drawing with Ballooning and BOM Design Check list Homework: Modular Fixture Design You have been given a solid model of a finished component called "Gearplate". You will be responsible for creating a modular fixture in Solidworks to accommodate what would be considered "Operation#1, and Operation#2 on a CNC vertical machining center 1) You will research, find and download modular fixturing components to complete the task 2) Your fixture must be able to hold an aluminum blank that is 1/4Thk x 10 in x5 in for operation #1 3) Operation#1 must have locating and clamping of this plate in a solid but expeditious fashion, and its purpose is for hole drilling and internal pocket machining only 4) On THE SAME FIXTURE BLOCK You will have a new area or section assuming the internal features have already been machined will now locate and clamp internally on the now machined features. Some ideas would be expanding mandrels, vacuum table, or simply clearance fit large machined dowels with cap screws, etc. be creative This will allow the complete exterior 360deg machining of the perimeter of the gearplate On your drawing for this fixture, you should reference GD&T Symbols in FCF for things like flatness etc Marks will be added or subtracted for - ease of use for operator - speed of use for operator - Relevant use of GD&T on your drawing -Reference to Industry purchased components that you have researched and used such as clamps by Carrlane, or the De Staco company, Mitee Bite company, McMaster Carr etc.. Homework: Modular Fixture Design 7) Please give your drawing a drawing number and fixture number referring to the part name 8) Have Notes and INSTRUCTIONS on how to use the fixture Ex) Opl Locate blank on dowels and clamp with.... After Opl is complete flip part to Op2 location For op2 seat with...., and clamp with..... Run part for Op2 Debur when complete, etc... 9) See attachments for Solidworks model Gear Plate Part for this Due Date and Time: Check the Assignments tab in the ACTIVITIES Folder Exercise You will upload your Solidworks files to the Assignments folder as per usual. The requirements are the same as all design assignments All models All Detail Drawings (No Dwgs of Cots parts UNLESS you modified the part) Assy model Assy Drawing with Ballooning and BOM Design Check list

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock