Question: Identify the Key Performance Indicators (KPIs - i.e., what key things were being measured) and the business benefits that were achieved. 1. Introduction Production of

Identify the Key Performance Indicators (KPIs - i.e., what key things were being measured) and the business benefits that were achieved.

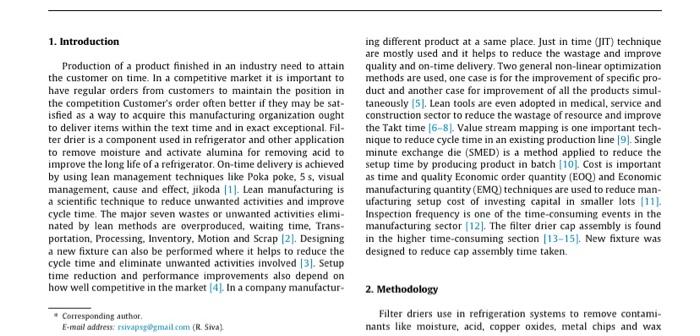

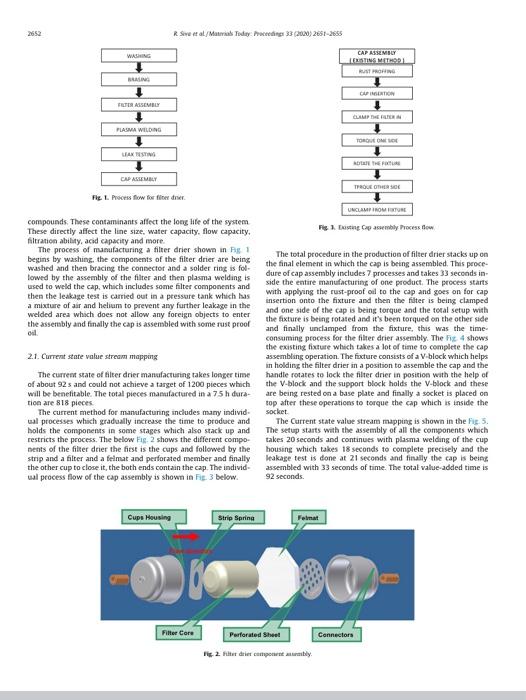

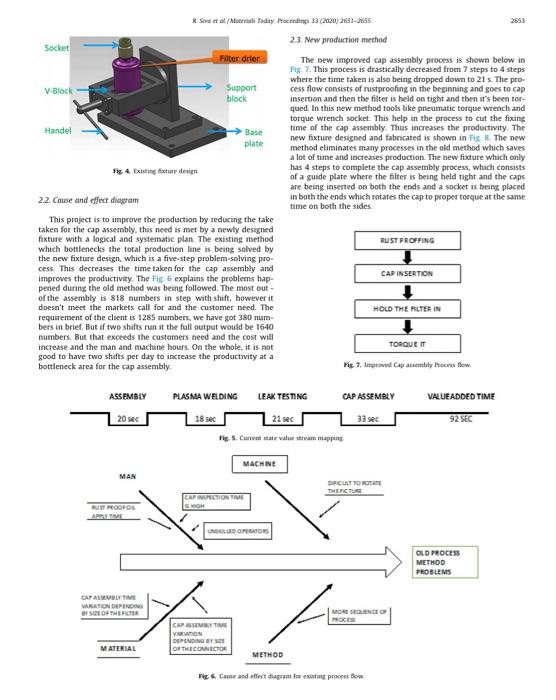

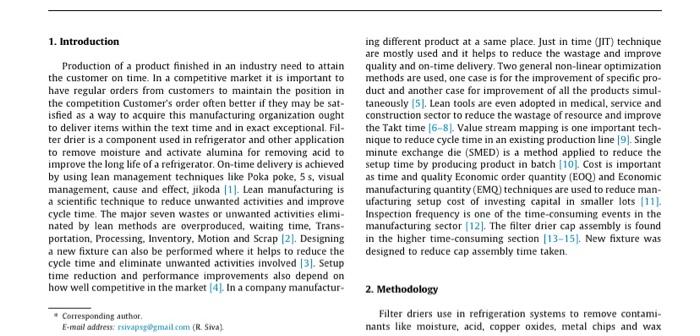

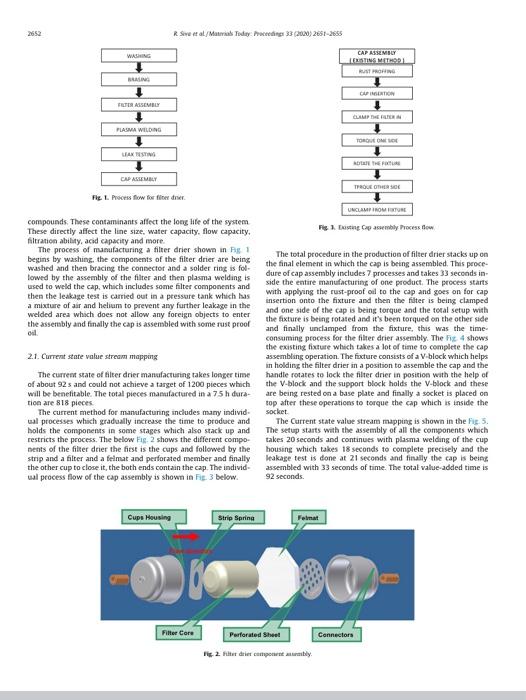

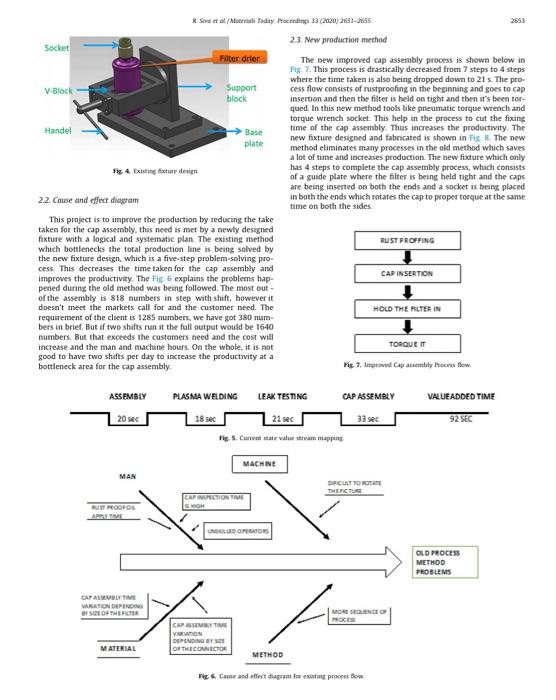

1. Introduction Production of a product finished in an industry need to attain the customer on time. In a competitive market it is important to have regular orders from customers to maintain the position in the competition Customer's order often better if they may be sat- isfied as a way to acquire this manufacturing organization ought to deliver items within the text time and in exact exceptional. Fil- ter drier is a component used in refrigerator and other application to remove moisture and activate alumina for removing acid to improve the long life of a refrigerator. On-time delivery is achieved by using lean management techniques like Poka poke, 5s, visual management, cause and effect, jikoda (1). Lean manufacturing is a scientific technique to reduce unwanted activities and improve cycle time. The major seven wastes or unwanted activities elimi- nated by lean methods are overproduced, waiting time, Trans- portation, Processing, Inventory, Motion and Scrap (2]. Designing a new fixture can also be performed where it helps to reduce the cycle time and eliminate unwanted activities involved 13). Setup time reduction and performance improvements also depend on how well competitive in the market (4]. In a company manufactur- ing different product at a same place. Just in time (JIT) technique are mostly used and it helps to reduce the wastage and improve quality and on-time delivery. Two general non-linear optimization methods are used, one case is for the improvement of specific pro- duct and another case for improvement of all the products simul- taneously (5]. Lean tools are even adopted in medical service and construction sector to reduce the wastage of resource and improve the Takt time 6-81. Value stream mapping is one important tech- nique to reduce cycle time in an existing production line 9). Single minute exchange die (SMED) is a method applied to reduce the setup time by producing product in batch (10]. Cost is important as time and quality Economic order quantity (EOQ) and Economic manufacturing quantity (EMO) techniques are used to reduce man- ufacturing setup cost of investing capital in smaller lots (11) Inspection frequency is one of the time-consuming events in the manufacturing sector (12). The filter drier cap assembly is found in the higher time-consuming section (13-15). New fixture was designed to reduce cap assembly time taken 2. Methodology Filter driers use in refrigeration systems to remove contami. nants like moisture, acid, copper oxides, metal chips and wax Corresponding author E-mail address: sivapeggmail.com (R. Swa). 2652 Revetal/Mais Today wings 33 (2020) 265-2655 WASHING CAP ASSEMBLY LESTING METHOD BALI TRTEN ASSEMBLY PLASMA WELDING LAKUSTING CAP ASSEMBLY TROUE OTHER SO Fig. Process flow files der UNCLAMP TROM STORE Fisting Capably hocess flow compounds. These contaminants affect the long life of the system These directly all the line size, water capacity, flow capacity. filtration ability, acid capacity and more The process of manufacturing a filter drier shown in Rg 1 begins by washing the components of the filter drier are being washed and then bracing the connector and a solder ring is fol- lowed by the assembly of the filter and then plasma welding is used to weld the cap, which includes some filter components and then the leakage test is carried out in a pressure tank which has a mixture of air and helium to prevent any further leakage in the welded area which does not allow any foreign objects to enter the assembly and finally the cap is assembled with some rust proof ol 2.1. Current state value stream mapping The current state of filter drier manufacturing takes longer time of about 92 s and could not achieve a target of 1200 pieces which will be benefitable. The total pieces manufactured in a 75 h dura- tion are 818 pieces The current method for manufacturing includes many individ ual processes which gradually increase the time to produce and holds the components in some stages which also stack up and restricts the process. The below Fig. 2 shows the different compo- nents of the filter drier the first is the cups and followed by the strip and a filter and a felmat and perforated member and finally the other cup to close it, the both ends contain the cap. The individ- ual process flow of the cap assembly is shown in Fig. 3 below. The total procedure in the production of filter drier stacks up on the final element in which the cap is being assembled. This proce- dure of cap assembly includes 7 processes and takes 33 seconds in side the entire manufacturing of one product. The process starts with applying the rust-proof oil to the cap and goes on for cap insertion onto the fixture and then the filter is being clamped and one side of the cap is being torque and the total setup with the fixture is being rotated and it's been torqued on the other side and finally unclamped from the fixture, this was the time consuming process for the filter drier assembly. The Fix 4 shows the existing fixture which takes a lot of time to complete the cap assembling operation. The fixture consists of a V-block which helps in holding the filter drier in a position to assemble the cap and the handle rotates to lock the filter drier in position with the help of the V-block and the support block holds the V-block and these are being rested on a base plate and finally a socket is placed on top after these operations to torque the cap which is inside the socker The Current state value stream mapping is shown in the rig 5. The setup starts with the assembly of all the components which takes 20 seconds and continues with plasma welding of the cup housing which takes 18 seconds to complete precisely and the leakage test is done at 21 seconds and finally the cap is being assembled with 33 seconds of time. The total value-added time is 92 seconds Cups Housing Strip Spring Felmat Filter Core Perforated Sheet Connectors Fig. 2. filter directly Swal Material Today Proceeding 33 (2020) 265-2655 2653 2.3 New production method Socket Filter drier The new improved cap assembly process is shown below in Fig. 7. This process is drastically decreased from 7 steps to 4 steps where the time taken is also being dropped down to 21 s. The pro- V-Block Support cess flow consists of rustproofing in the beginning and goes to cap block insertion and then the filter is held on tight and then it's been tor- qued. In this new method tools like Pneumatic torque Wrench and torque Wrench socket. This help in the process to cut the fixing Handel Base time of the cap assembly. Thus increases the productivity. The new fixture designed and fabricated is shown in Fig. 8. The new plate method eliminates many processes in the old method which saves a lot of time and increases production. The new fixture which only TE 4 Etting future design has 4 steps to complete the cap assembly process, which consists of a guide plate where the filter is being held tight and the caps are being inserted on both the ends and a socket is being placed 22. Cause and effect diagram in both the ends which rotates the cap to proper torque at the same time on both the sides. This project is to improve the production by reducing the take taken for the cap assembly. this need is met by a newly designed fixture with a logical and systematic plan. The existing method RUST PROFFING which bottlenecks the total production line is being solved by the new fixture design, which is a five-step problem-solving pro- cess. This decreases the time taken for the cap assembly and improves the productivity. The explains the problems hap CAP INSERTION pened during the old method was being followed. The most out of the assembly is 818 numbers in step with shift, however it doesn't meet the markets call for and the customer need. The HOLD THE RLTER IN requirement of the client is 1285 numbers, we have got 380 num- bers in brief. But if two shifts run it the full output would be 1640 numbers. But that exceeds the customers need and the cost will increase and the man and machine hours. On the whole, it is not TORQUE IT good to have two shifts per day to increase the productivity at a bottleneck area for the cap assembly Fig 1. Improved Capamtly les flow ASSEMBLY PLASMA WELDING LEAK TESTING CAP ASSEMBLY VALUE ADDED TIME 20 sec 92 SEC 18 sec 21 sec Fi S. Current state vara min MACHINE MAN DIFICULT TOOTH CAPINGPICTION TIME M RUS ROOF UNGGU OPERATOR OLD PROCESS METHOD PROBLEMS CAPAMBU TIME VARATION DEPENDING SEOFTHEHOTE MORE SOLENCE OF MOCES CAPASEMOTIVE VON DEPENDING DIT CONNECTOR MATERIAL METHOD Fig. 6. Come and effect diagram for existing process flow

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock